On-site mixed emulsion explosive loading device and method for tunnel peripheral holes

A technology of mixing and emulsifying explosives on site, which is applied in blasting and other directions, can solve problems such as not being able to meet the quality requirements of blasting around tunnel holes, and achieve the effects of ensuring smooth blasting effects, saving manpower, and optimizing hole network parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

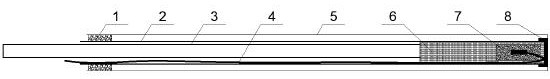

[0025] Example 1, see figure 1 , an on-site mixed emulsion explosive charging device for tunnel peripheral holes, comprising a charging sleeve 2 located in the blast hole 5, a casing sealing member 8 and an elastic fixing ring 1; The bottom of the hole of 5 extends to the orifice, the casing sealing member 8 seals the nozzle of the charging casing 2 at the bottom of the blast hole, and the elastic fixing ring 1 is arranged at the orifice of the blast hole 5, and is stuck on the charging sleeve. Between the outer circumference of the tube 2 and the hole wall of the blast hole 5, the charge sleeve 2 is used to install the detonating charge pack 7 with the detonator 4 and to mix the emulsion explosives on the filling site.

[0026] Wherein, the diameter of the blast hole 5 is 42mm~52mm, the depth is 1m~5m, the outer diameter of the charging sleeve 2 is 28mm~32mm, the inner diameter is 26mm~30mm or the wall thickness is 1mm~2mm. The elastic fixing ring 1 is made of foam sponge ho...

Embodiment 2

[0027] Example 2, combined figure 1 , an on-site mixed emulsion explosive charging method for tunnel peripheral holes is implemented based on the on-site mixed emulsion explosive charging device for tunnel peripheral holes in Example 1, and the on-site mixed emulsion explosive charging pipe 3 Fill the charge casing 2 with low-density on-site mixed emulsion explosives with a density of 0.85g / cm³~1.0g / cm³ to a set amount, and the specific charge amount is determined by the blasting design.

[0028] The method specifically includes the following steps:

[0029] S1, the charging device installation: according to the casing sealing member 8 is placed at the bottom of the blast hole 5, the charging casing 2 is fixed to the blast hole 5 by the elastic fixing ring 1, and the scene of the embodiment 1 is used for the tunnel peripheral hole. The mixed emulsion explosive charging device is installed in the blast hole 5;

[0030] S2, the installation of the detonating charge bag 7: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com