NCVM finish paint as well as preparation method and application thereof

A technology of topcoat and reaction monomer, which is applied to the device for coating liquid on the surface, vacuum evaporation plating, coating, etc. The crystals are closely arranged and the hand feels fine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0201] The preparation method of Primer in the embodiment of the present invention is made up of the following steps:

[0202] S1. After mixing the bifunctional urethane acrylate resin, the solvent-based urethane acrylic resin, the hexafunctional urethane acrylic resin and the monomer, preheat at 45°C for 30min; then add 1 / 3 volume of the mixed solvent, and stir at 1000r / min for 60min , to obtain the first mixture;

[0203] S2, adding a photoinitiator and a leveling agent to the first mixture prepared in step S1, and stirring at 1500 r / min for 10 min to prepare a second mixture;

[0204] S3. Add the remaining part of the mixed solvent, stir at 1200 r / min for 30 min, stir evenly, and filter with a 400-mesh filter cloth.

[0205] In the embodiment of the present invention, the second primer is prepared from the following preparation raw materials:

[0206] Difunctional urethane acrylic resin (Japan Synthetic Chemical UV-3000B): 25%, solvent-based urethane acrylic resin (Changx...

Embodiment 1

[0217] This embodiment is an NCVM topcoat and its preparation method and application.

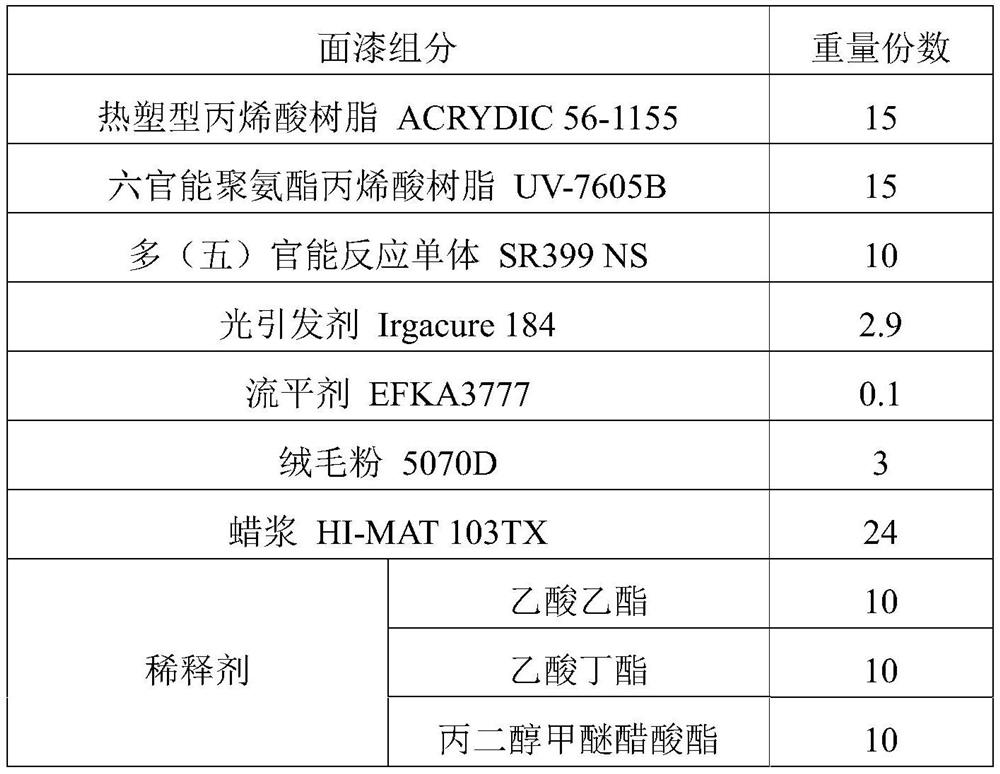

[0218] The preparation raw materials and parts by weight of NCVM topcoat in the present embodiment are shown in Table 1 below:

[0219] Table 1. The parts by weight of each preparation raw material in this embodiment

[0220]

[0221] The preparation method of NCVM topcoat in the present embodiment is made up of the following steps:

[0222] S1. After mixing thermoplastic acrylic resin, hexafunctional urethane acrylic resin and multifunctional reaction monomer, preheat at 45°C for 30min, add 1 / 3 volume of diluent, stir at 1500r / min for 60min, and stir evenly; producing a first mixture;

[0223] S2, adding a photoinitiator and a leveling agent to the first mixture prepared in step S1, stirring at 1500 r / min for 15 min, and stirring evenly; preparing a second mixture;

[0224] S3, adding fluff powder to the second mixture obtained in step S2 while stirring at a rotating speed of 800 r / m...

Embodiment 2

[0238] This embodiment is an NCVM topcoat and its preparation method and application.

[0239] The preparation raw materials and parts by weight of NCVM topcoat in the present embodiment are shown in Table 2 below:

[0240] Table 2. The parts by weight of each preparation raw material in the present embodiment

[0241]

[0242]

[0243] The preparation method of the topcoat in this example is the same as that in Example 1.

[0244] The method for preparing the topcoat as a coating in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com