Tower-shaped staggered laminated screen

A staggered and stacked technology, which is applied in the direction of screening, solid separation, and separation of solids from solids with airflow, can solve the problem of insufficient compactness of the horizontal layout of stacked screens, low utilization rate of screen surfaces, and material layers. Problems such as uneven thickness, to achieve the effect of increasing the residence time and the number of collisions, compact structure, and reducing the speed of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

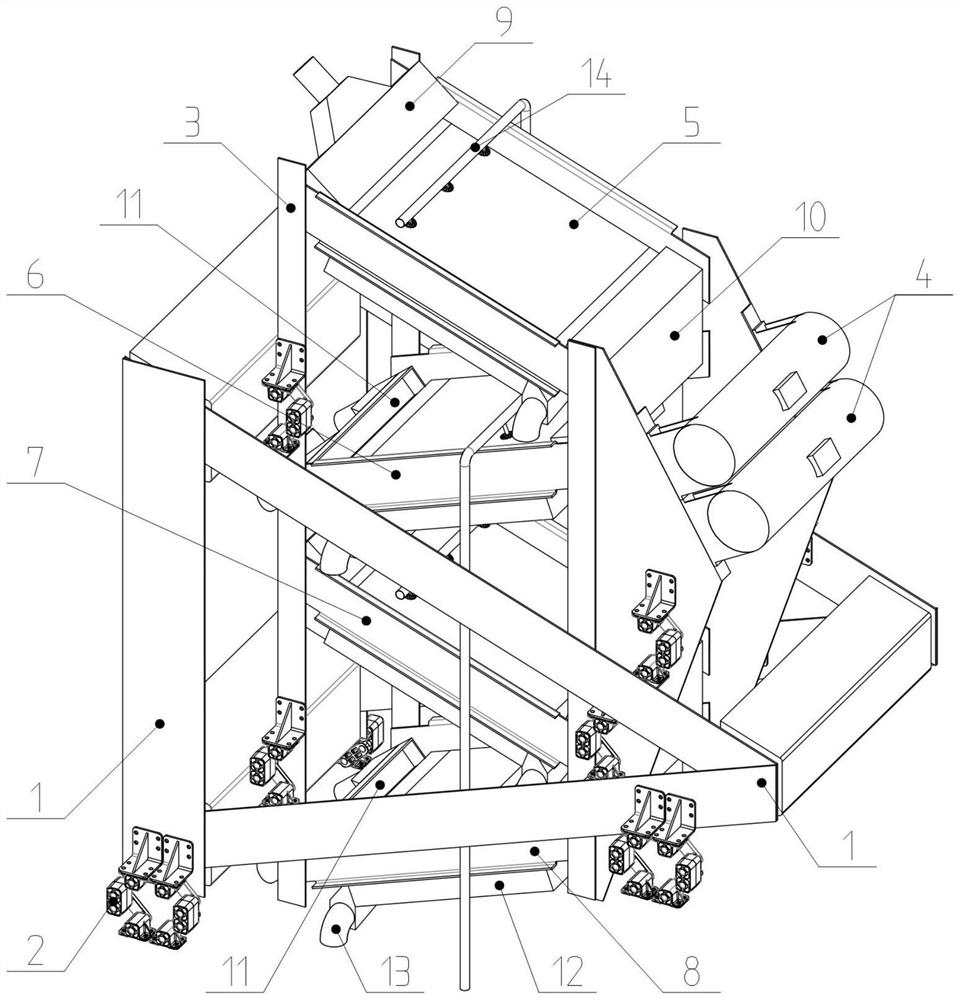

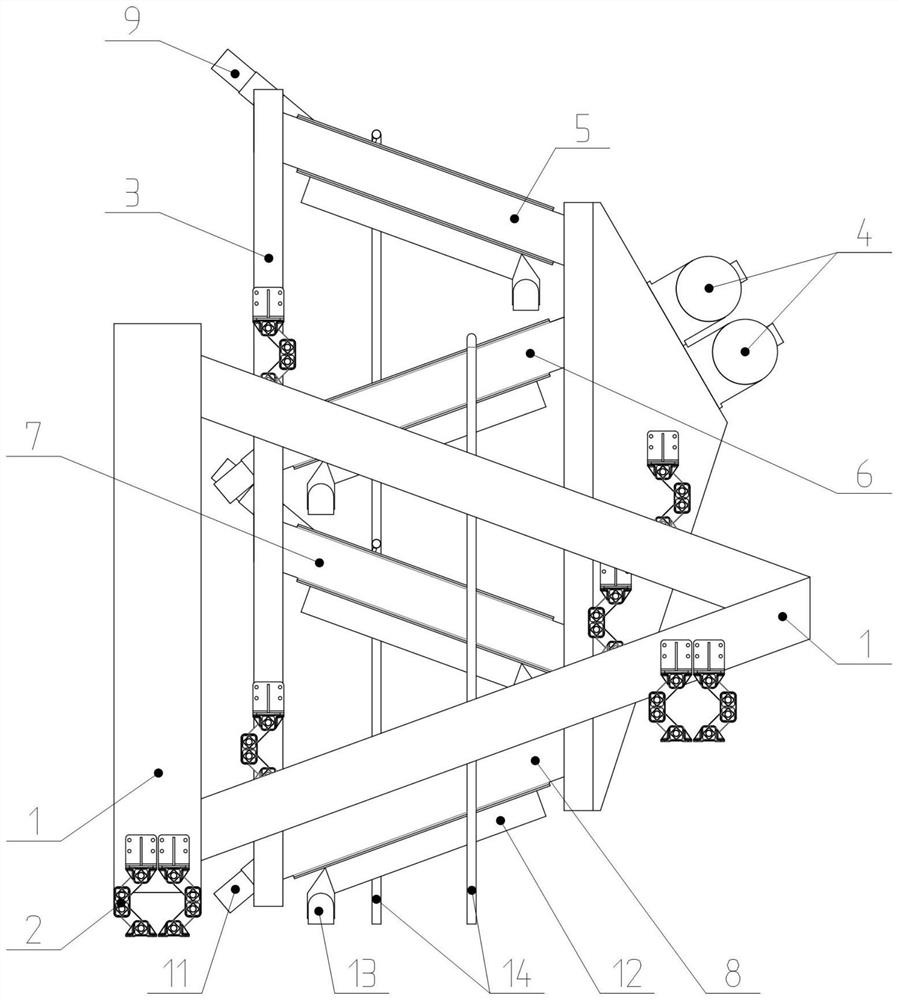

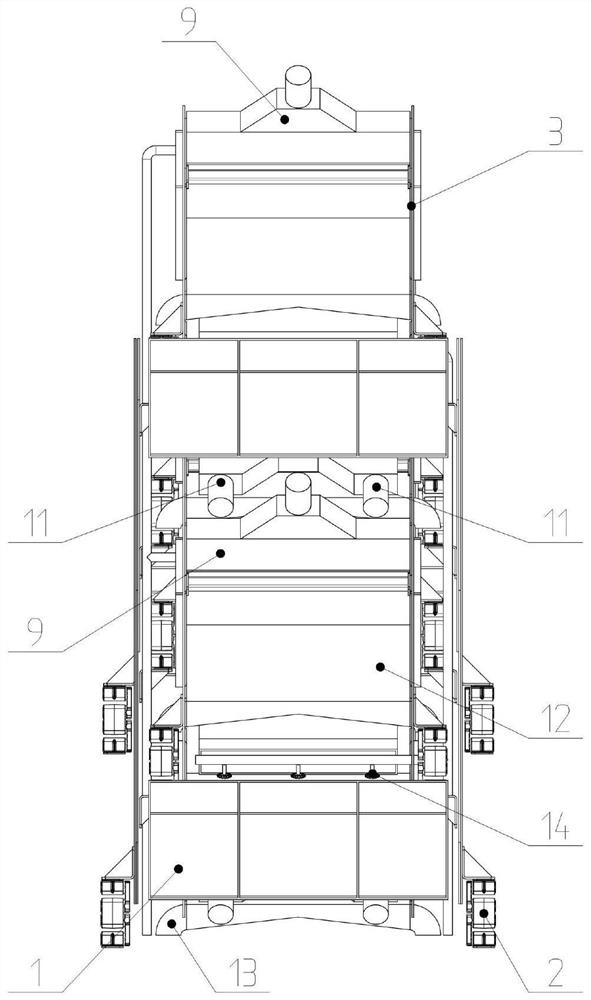

[0021] see figure 1 — Figure 4 , a tower-shaped staggered laminated screen, which includes a fixed frame 1, a screening device, an excitation device, a feeding port 9, an oversize chute 10 and a discharge device; the fixed frame 1 is connected to the The foundation; the screening device includes a movable frame 3 connected with the fixed frame 1 through the ROSTA spring 2 and the screen frames 5-8 arranged on the movable frame 3 obliquely and staggered; the excitation device includes a movable frame 3 connected to the movable frame 3 Two vibrating motors 4 running synchronously and reversely on the top; the discharge device includes the discharge port 11 for the over-screen material, the under-screen material collection tank 12 and the under-screen material discharge port 13; the four-layer screen frames 5-8 are made of spray The water spray device 14 evenly provides spray water.

[0022] In this embodiment, the fixed frame 1 is triangular, and the fixed frames 1 on both si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap