Crushed material collecting device for rice crust production

A collection device and debris technology, applied in cleaning methods and utensils, separating solids from solids with airflow, solid separation, etc., can solve the problems of not being able to achieve multiple screening effects, unfavorable external personnel operation and processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be clearly and completely described below with reference to the embodiments. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

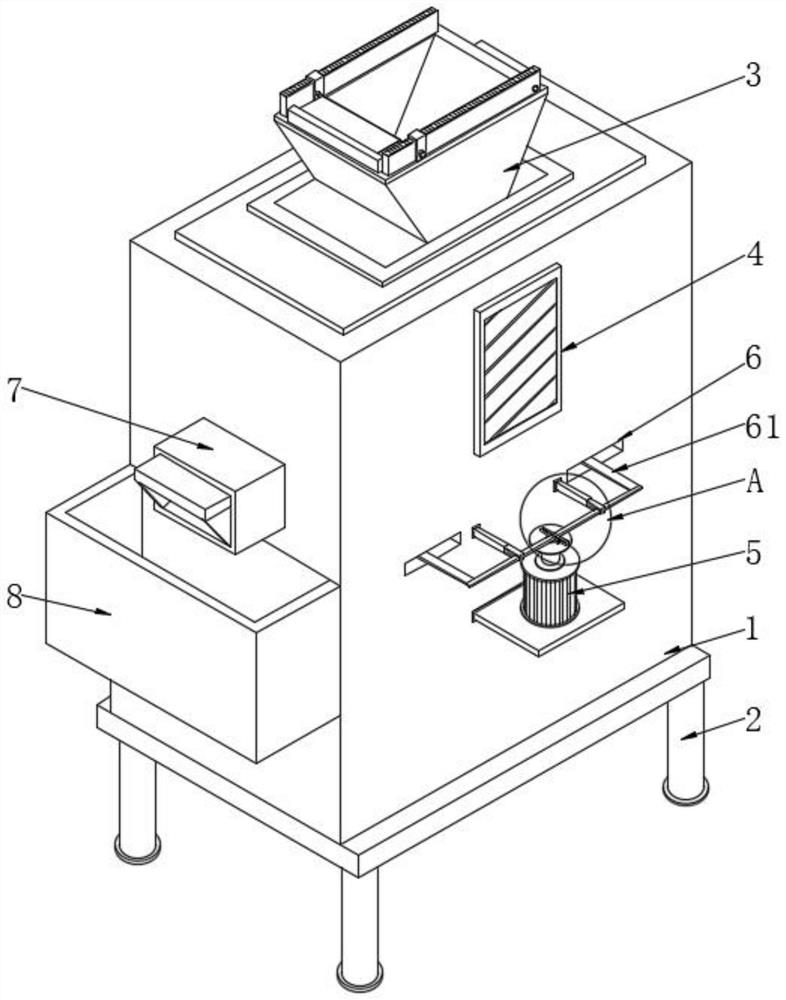

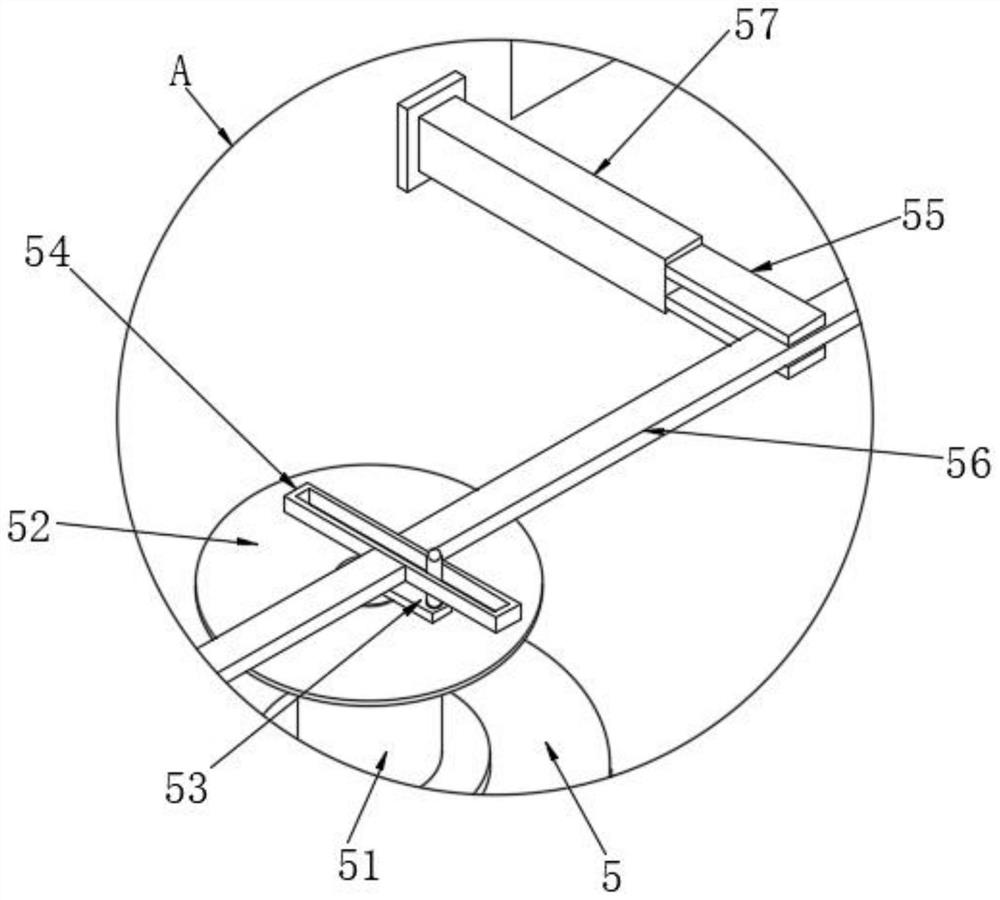

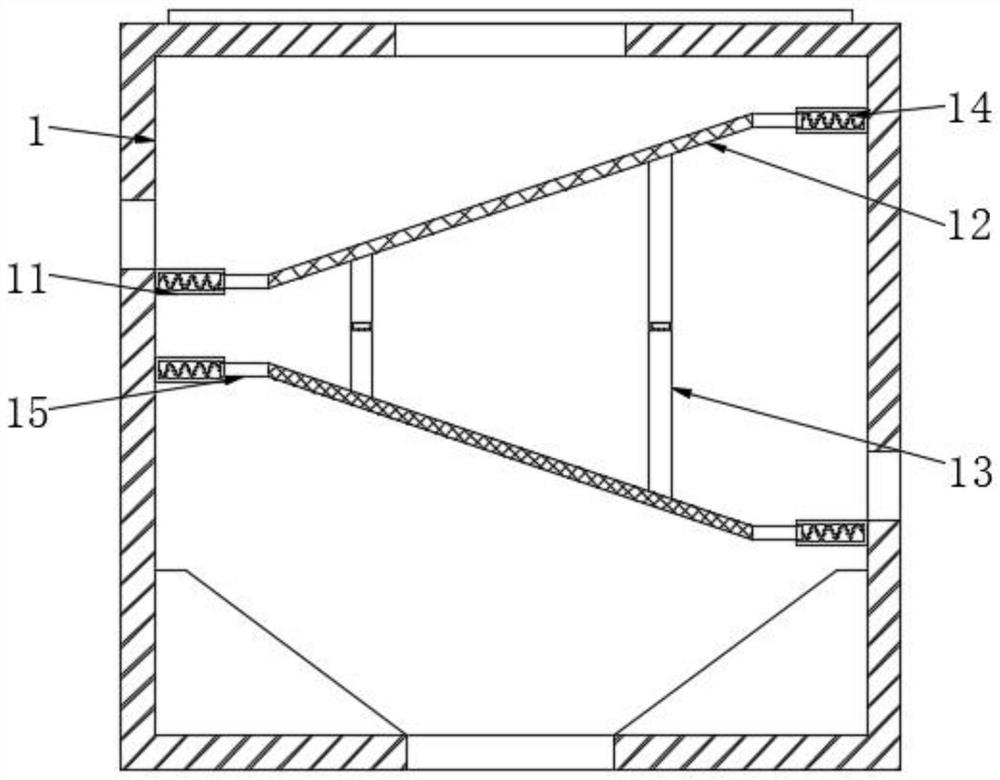

[0021] see figure 1 , the present application provides a scrap collection device for rice cooker production, including a frame body 1, the lower end of the frame body 1 is provided with support columns 2 at the four peripheral corners, and the upper end of the frame body 1 is provided with a hopper 3 in the middle. A servo motor 5 is provided at the lower middle of the front end of the frame body 1, and a rotating shaft 51 is provided at the output end of the servo motor 5. The upper end of the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com