Gallium nitride crystal production equipment

A production equipment, gallium nitride technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of poor effect of gallium nitride crystal, waste construction time of construction personnel, etc. The effect of good body mass and speeding up the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

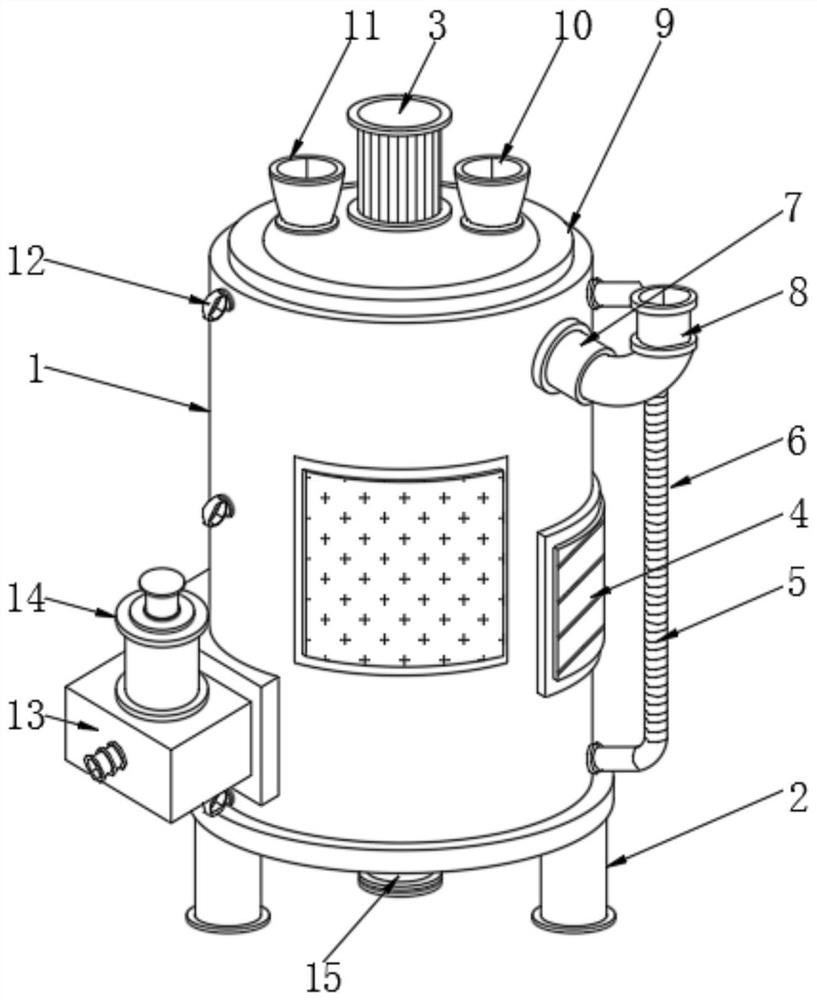

[0031] A gallium nitride crystal production equipment, comprising a barrel body 1, support columns 2 are fixedly installed at the four peripheral corners of the lower surface of the barrel body 1, an upper cover plate 9 is fixedly installed on the upper surface of the barrel body 1, and the upper cover plate 9 A servo motor 3 is fixedly installed in the middle of the surface, a first feed pipe 10 is fixedly installed on the upper surface of the upper cover plate 9 at one side of the servo motor 3, and the upper surface of the upper cover plate 9 is located at the other side of the servo motor 3 A second feed pipe 11 is fixedly installed, a liquid crystal touch display 4 is fixedly installed on one side of the annular outer surface of the barrel body 1, and a discharge pipe 15 is fixedly installed at the middle position inside the barrel body 1, and the annular outer surface of the barrel body 1 is close to A connecting pipe 7 is fixedly installed at one side of the upper end, a...

Embodiment 2

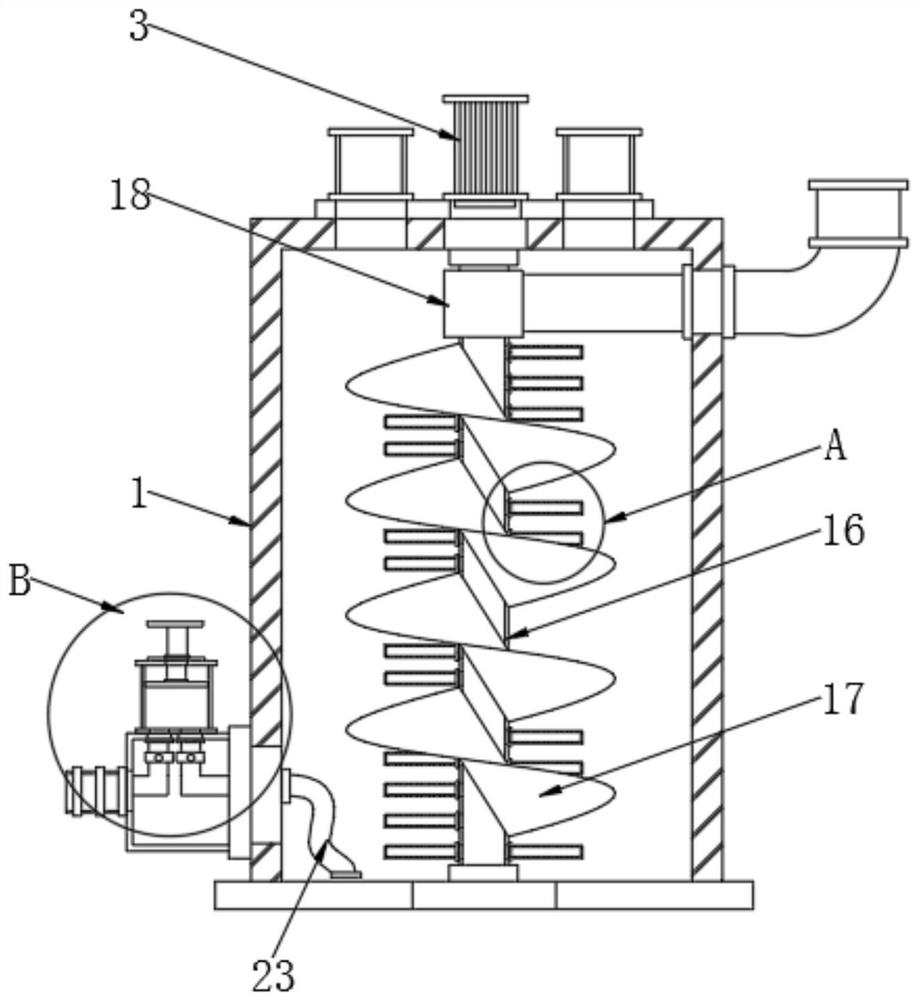

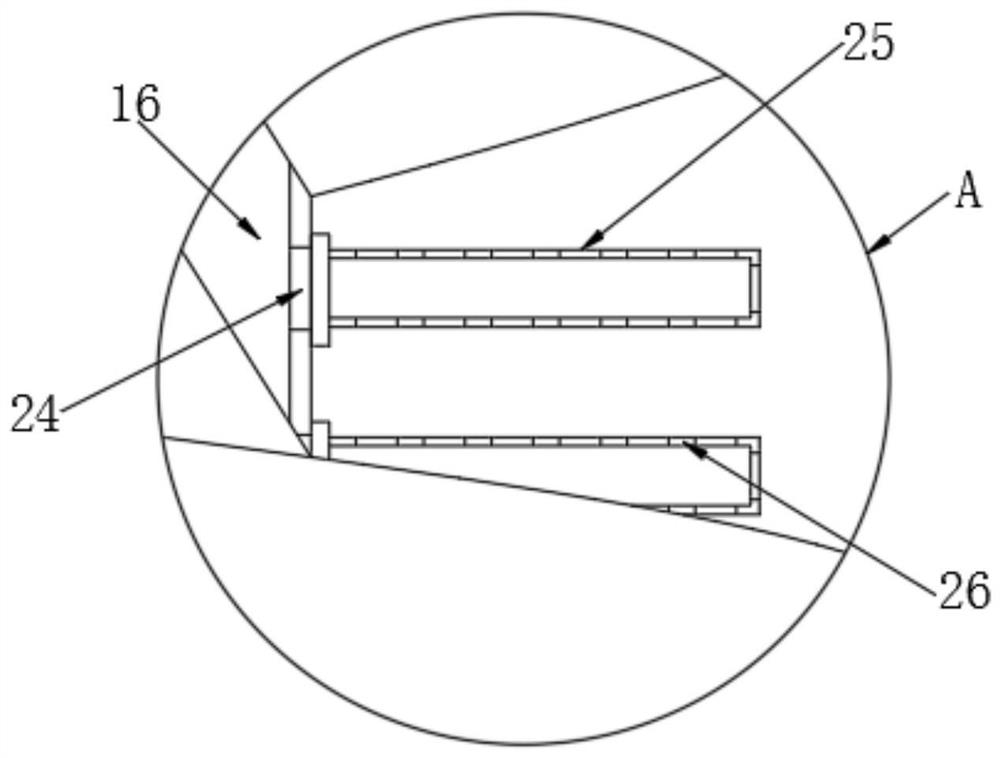

[0034] A gallium nitride crystal production equipment, comprising a barrel body 1, support columns 2 are fixedly installed at the four peripheral corners of the lower surface of the barrel body 1, an upper cover plate 9 is fixedly installed on the upper surface of the barrel body 1, and the upper cover plate 9 A servo motor 3 is fixedly installed in the middle of the surface, a first feed pipe 10 is fixedly installed on the upper surface of the upper cover plate 9 at one side of the servo motor 3, and the upper surface of the upper cover plate 9 is located at the other side of the servo motor 3 A second feed pipe 11 is fixedly installed, a liquid crystal touch display 4 is fixedly installed on one side of the annular outer surface of the barrel body 1, and a discharge pipe 15 is fixedly installed at the middle position inside the barrel body 1, and the annular outer surface of the barrel body 1 is close to A connecting pipe 7 is fixedly installed at one side of the upper end, a...

Embodiment 3

[0037] A gallium nitride crystal production equipment, comprising a barrel body 1, support columns 2 are fixedly installed at the four peripheral corners of the lower surface of the barrel body 1, an upper cover plate 9 is fixedly installed on the upper surface of the barrel body 1, and the upper cover plate 9 A servo motor 3 is fixedly installed in the middle of the surface, a first feed pipe 10 is fixedly installed on the upper surface of the upper cover plate 9 at one side of the servo motor 3, and the upper surface of the upper cover plate 9 is located at the other side of the servo motor 3 A second feed pipe 11 is fixedly installed, a liquid crystal touch display 4 is fixedly installed on one side of the annular outer surface of the barrel body 1, and a discharge pipe 15 is fixedly installed at the middle position inside the barrel body 1, and the annular outer surface of the barrel body 1 is close to A connecting pipe 7 is fixedly installed at one side of the upper end, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com