Sintering flue gas low-temperature SCR denitration system and catalyst online in-situ regeneration system

A sintering flue gas and low-temperature technology, which is applied in the direction of reducing greenhouse gases, combustion technology mitigation, and climate sustainability. It can solve problems such as damage to low-temperature catalysts, high cost, and sulfur poisoning of low-temperature SCR denitrification catalysts, so as to reduce energy consumption and Effects of operating costs, improving operational stability, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

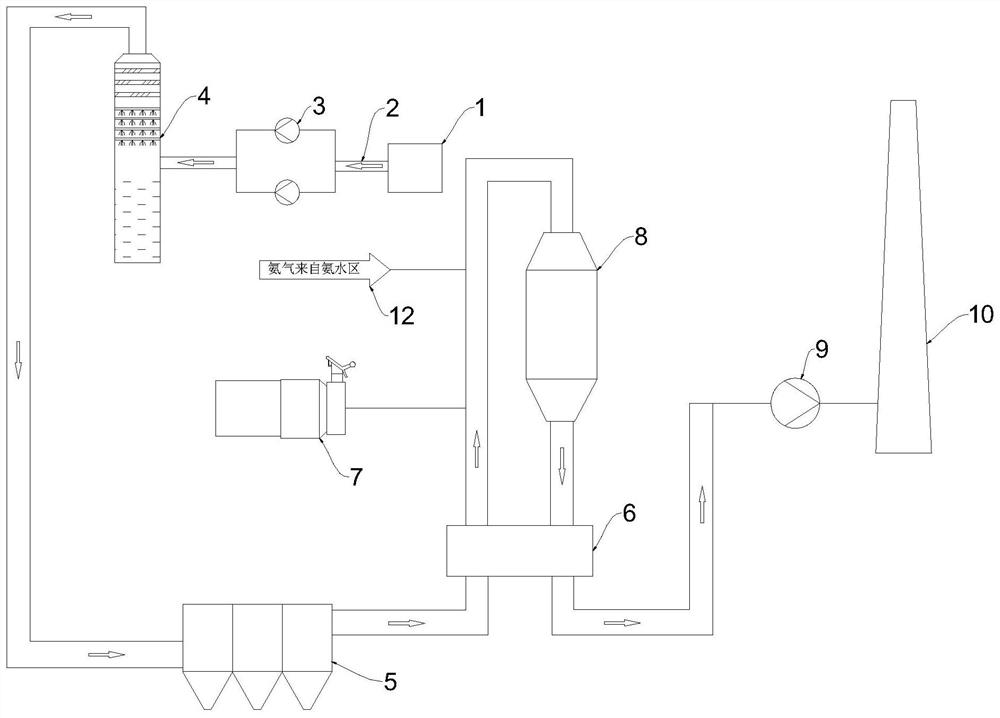

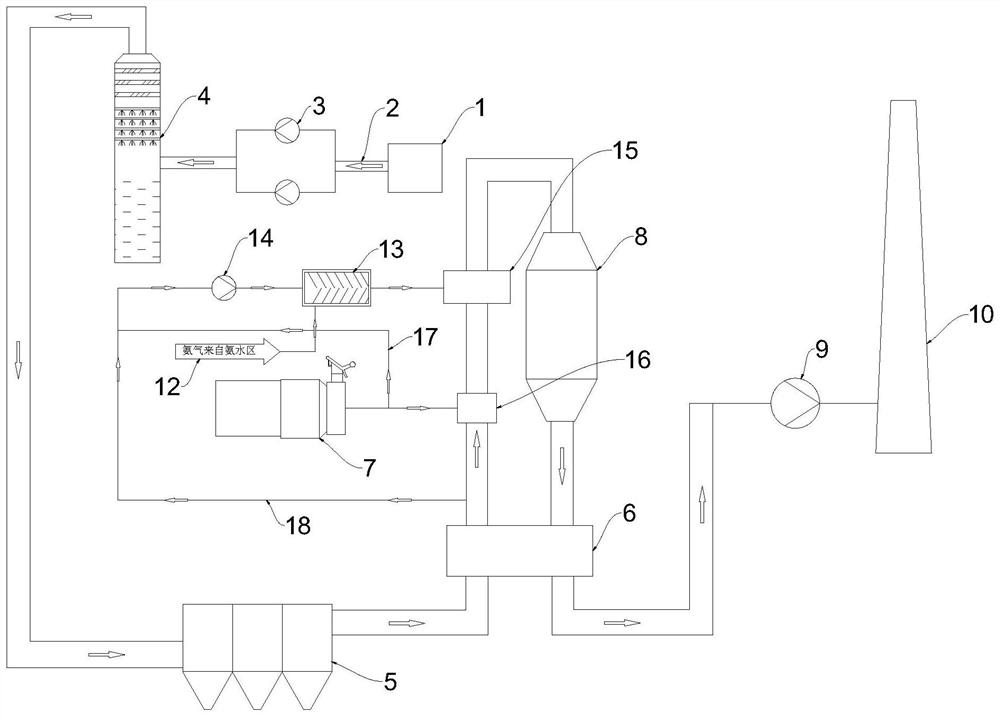

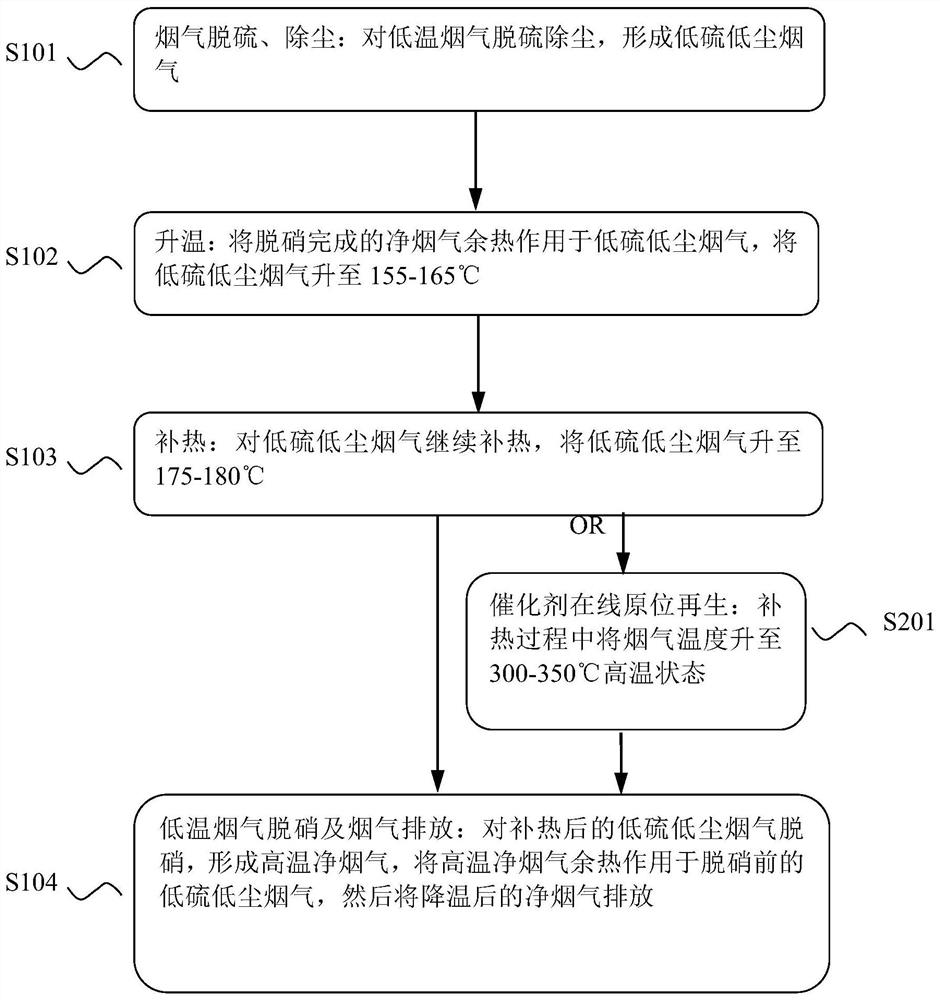

[0024] see figure 1 As shown, a low-temperature SCR denitration system for sintering flue gas described in this embodiment includes a desulfurization tower 4. The flue gas input end of the desulfurization tower 4 introduces the flue gas generated by the sintering machine 1, and the flue gas passes between the desulfurization tower 4 and the sintering machine 1. The gas pipeline 2 is connected, and the main exhaust fan 3 is connected with the flue gas pipeline 2. The main exhaust fan 3 is used to input the flue gas in the flue gas pipeline 2 into the desulfurization tower 4, and the flue gas output end of the desulfurization tower 4 is connected to the dust collector 5. The input end is connected, the flue gas output end of the dust collector 5 is connected with the original flue gas inlet end of the heat exchanger 6, the original flue gas output end of the heat exchanger 6 is connected with the flue gas input end of the low temperature SCR denitration tower 8, and the low tempe...

Embodiment 2

[0034] The catalyst on-line in-situ regeneration system described in this embodiment includes a low-temperature SCR denitration system for sintering flue gas described in Embodiment 1, and the catalyst in the present invention is a low-temperature denitration catalyst.

[0035] When the low-temperature SCR denitration system for sintering flue gas is running, when the low-temperature catalyst needs to be regenerated online, there is no need to add additional equipment. It is only necessary to increase the gas consumption through the hot blast stove to increase the temperature of the original flue gas to a high temperature of 300-350 °C. The catalyst is analyzed and regenerated at a high temperature, and the surface active sites are recovered, so that the low-temperature SCR denitration catalyst can be regenerated online in-situ, and the regeneration generally lasts for 1-2 days; at the same time, the first to fifth steps in Example 1 can be repeated. , without affecting the den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com