Wafer alignment device and alignment method

A technology for aligning devices and wafers, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as complex structure and difficult debugging, and achieve compact structure, precise movement and power-off retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

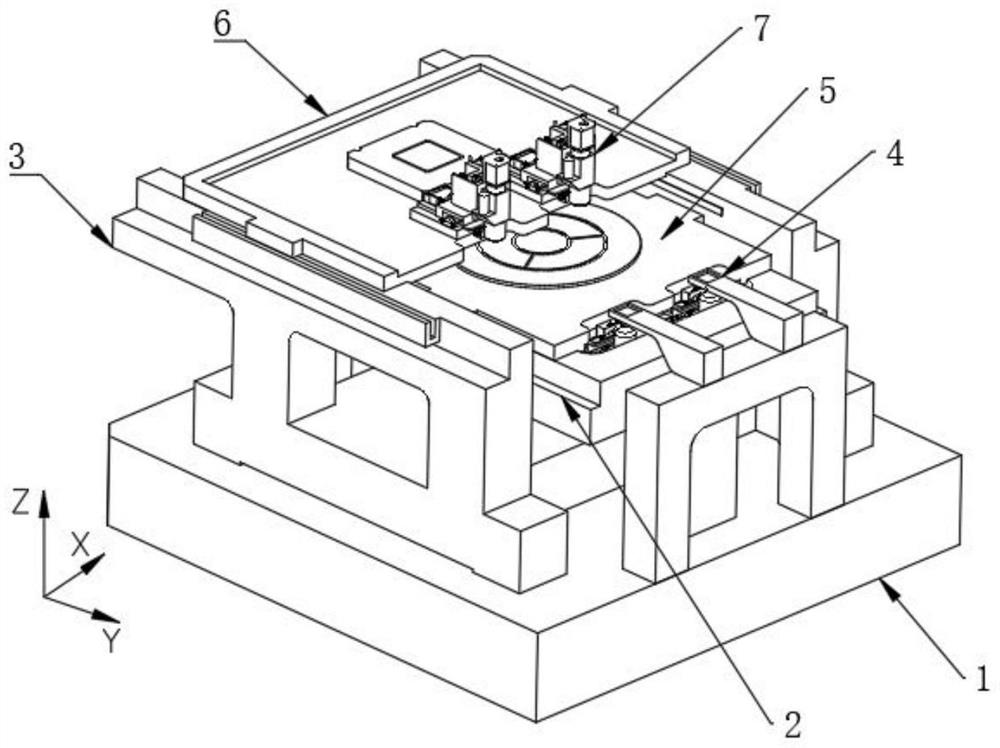

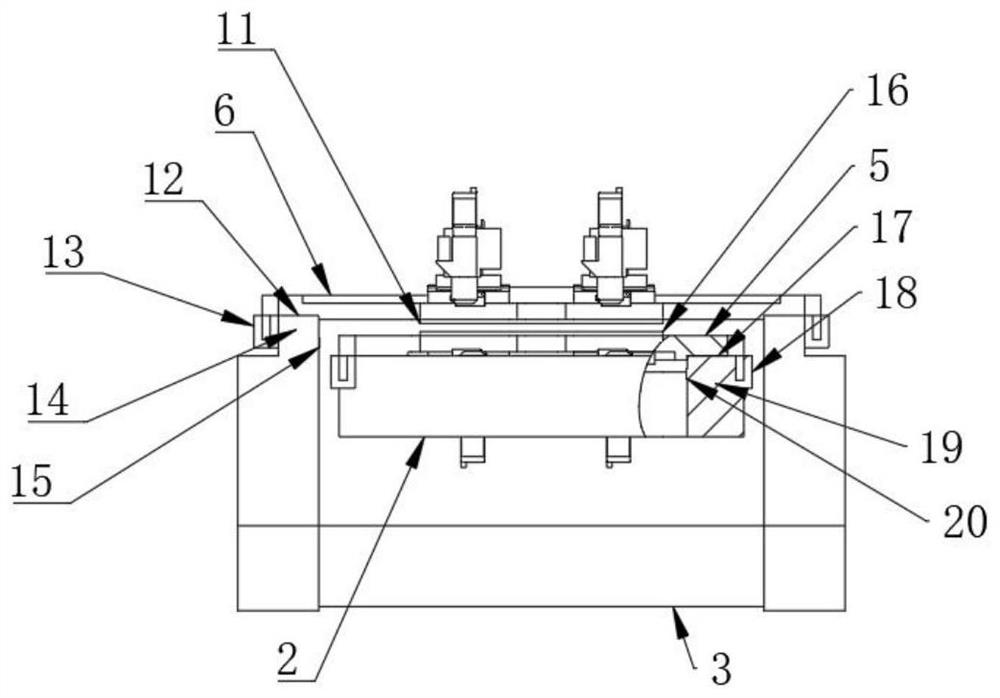

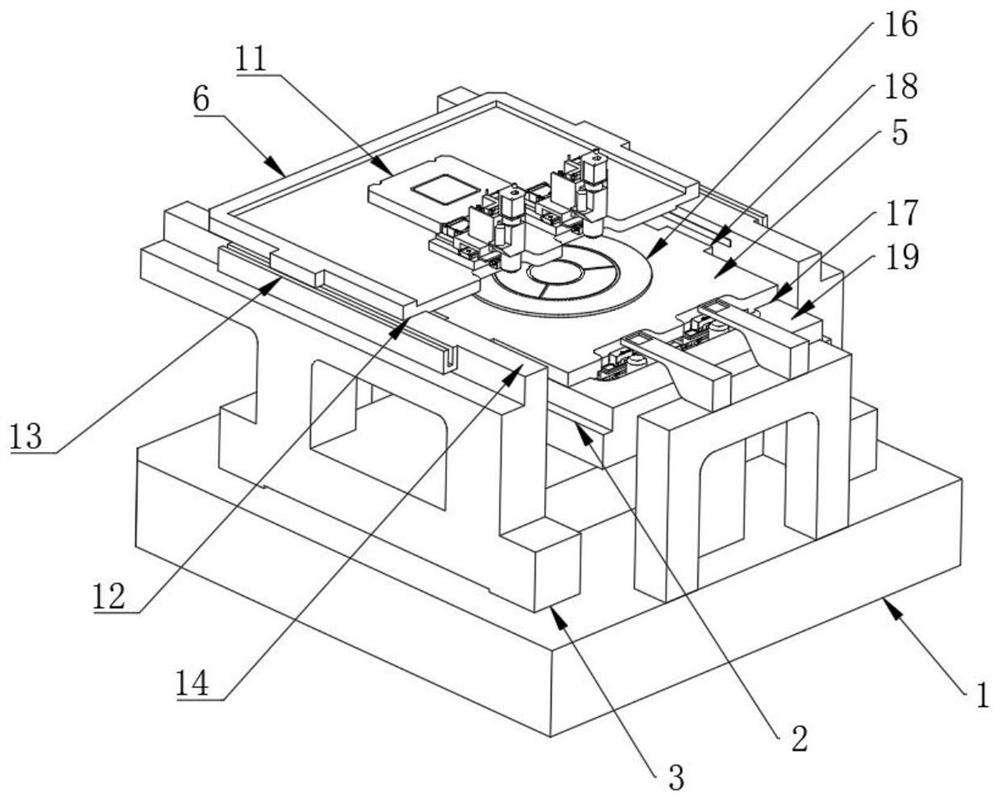

[0044] like Figure 1-3 As shown, a wafer alignment device includes a base 1, a lower motion stage 2 and an upper motion stage 3 are arranged above the base 1, two alignment marks 4 are installed on the base 1, and the upper The motion platform 3 is provided with an upper bearing platform 6 , and the lower motion platform 2 is provided with a lower bearing platform 5 ; two sets of vision systems 7 are respectively provided above the upper bearing platform 6 and below the lower bearing platform 5 .

[0045] Each set of vision systems 7 can move independently in X and Z directions. The two sets of vision systems above the upper platform 6 may be referred to as upper vision systems, and the two sets of vision systems below the lower platform 5 may be referred to as lower vision systems.

[0046] The base is made of marble, the upper surface of which is an air-floating surface, and the bottom of the upper motion table 3 is an air-floating block, which can float and fall on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com