High-definition electronic screen production quality intelligent monitoring and analyzing system based on machine vision

A production quality and intelligent monitoring technology, applied in image analysis, single semiconductor device testing, instruments, etc., can solve the problem of inability to ensure the stability and reliability of lamp beads, highlight the quality status of lamp beads, and display lamp beads intuitively Life expectancy and other issues, to achieve stability and reliability guarantee, improve quality monitoring effect, and improve operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The above content will be implemented in conjunction with the present invention below only to illustrate and illustrate the concept of the present invention. Those skilled in the art make various modifications or supplements to the described specific embodiments or replace them in similar ways. As long as it does not deviate from the concept of the invention or go beyond the scope defined by the claims, it shall belong to the protection scope of the present invention.

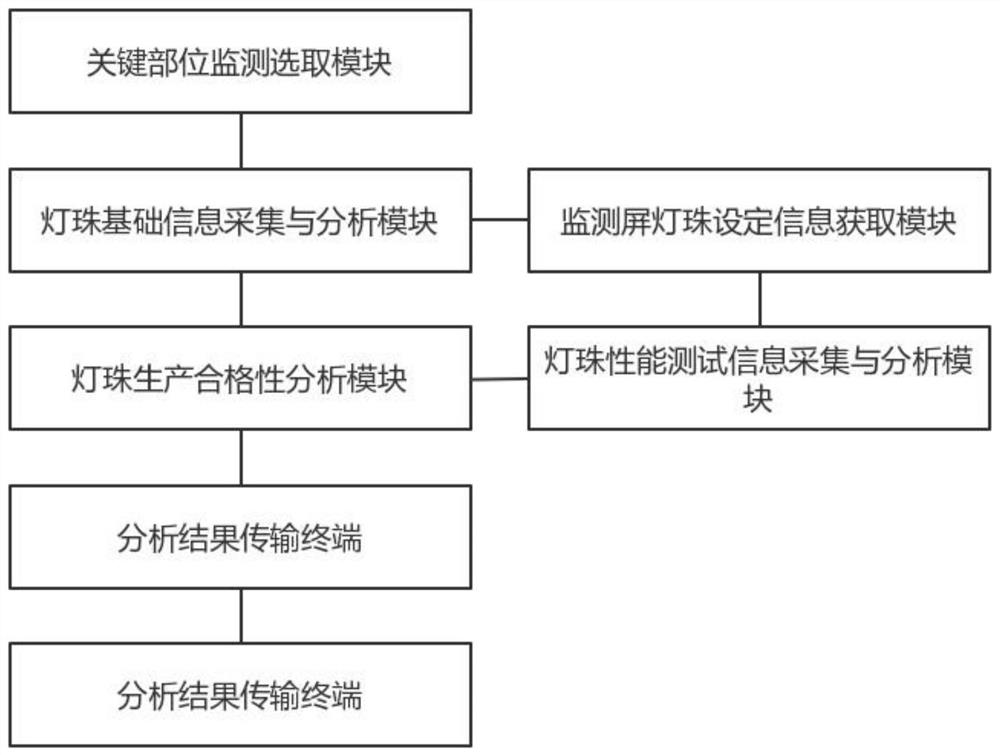

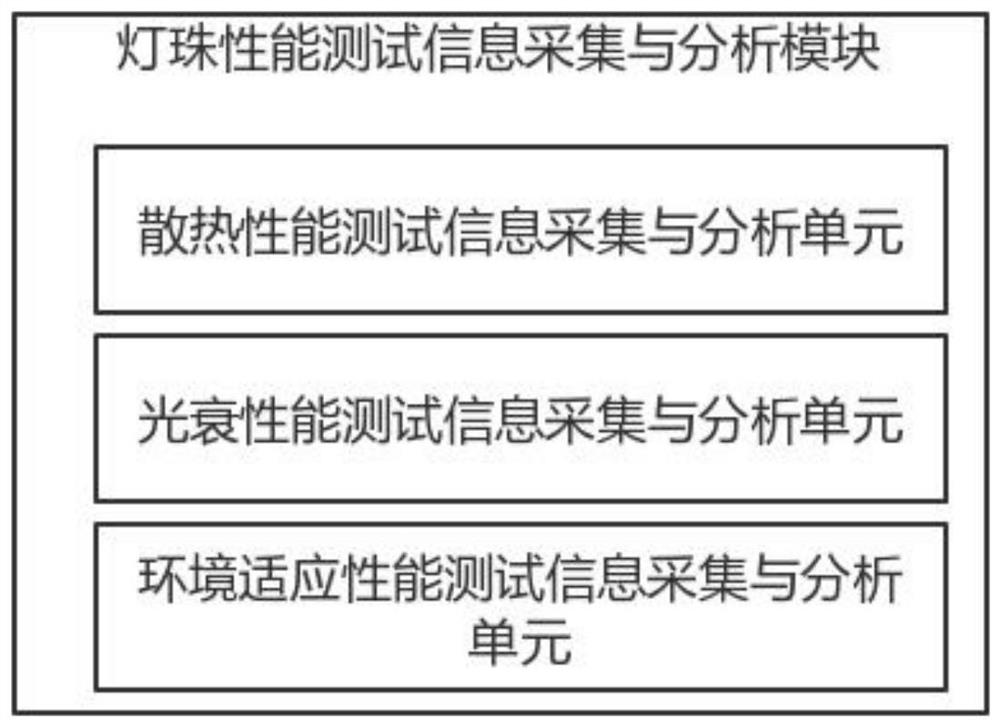

[0052] see figure 1 As shown, the present invention provides an intelligent monitoring and analysis system for the production quality of high-definition electronic screens based on machine vision. , lamp bead performance test information collection and analysis module, lamp bead production qualification analysis module, analysis result transmission terminal;

[0053] Based on the connection relationship shown in the figure, the lamp bead production qualification analysis module is respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com