Offshore wind turbine composite cylindrical foundation of support-free single-column structure

A technology for offshore wind turbines and cylindrical foundations, which is applied to the installation/support of wind turbine configuration, infrastructure engineering, construction, etc., and can solve problems such as reducing construction work time, increasing construction difficulty, and increasing wave receiving area, so as to reduce offshore wind turbines. operating time, reducing berthing impact, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

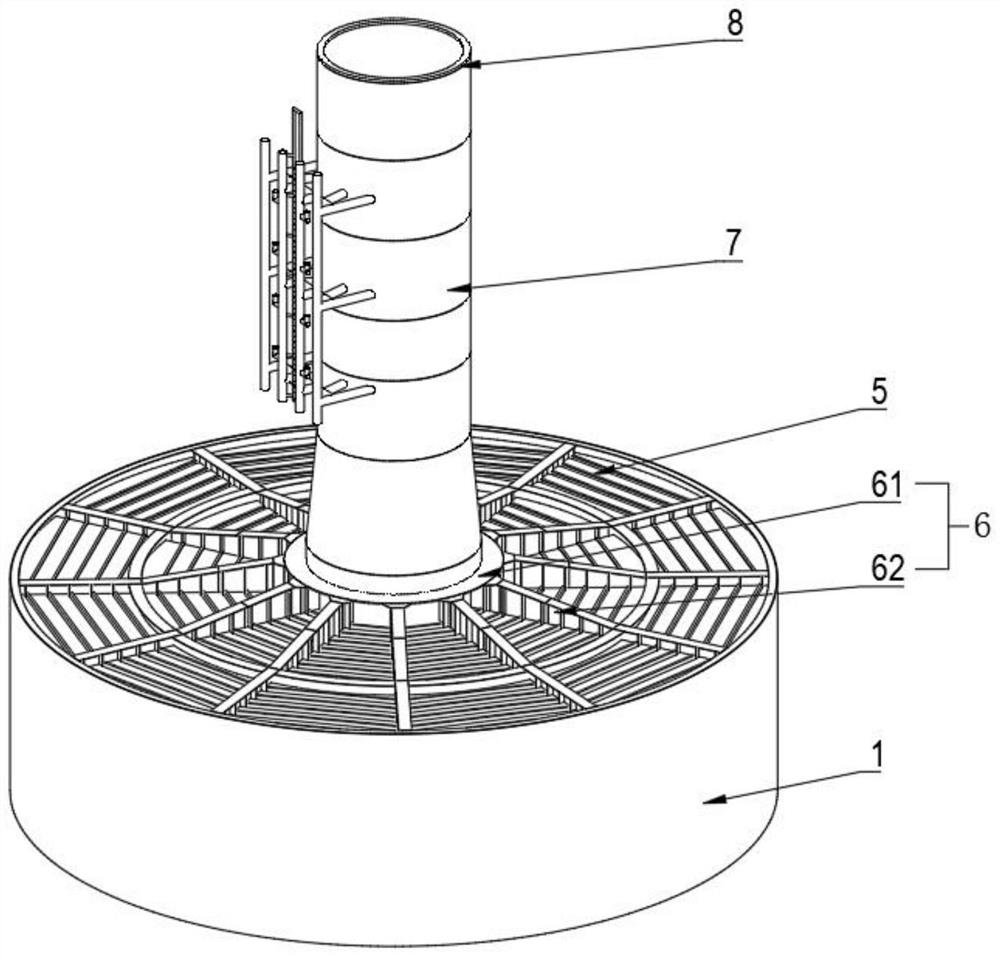

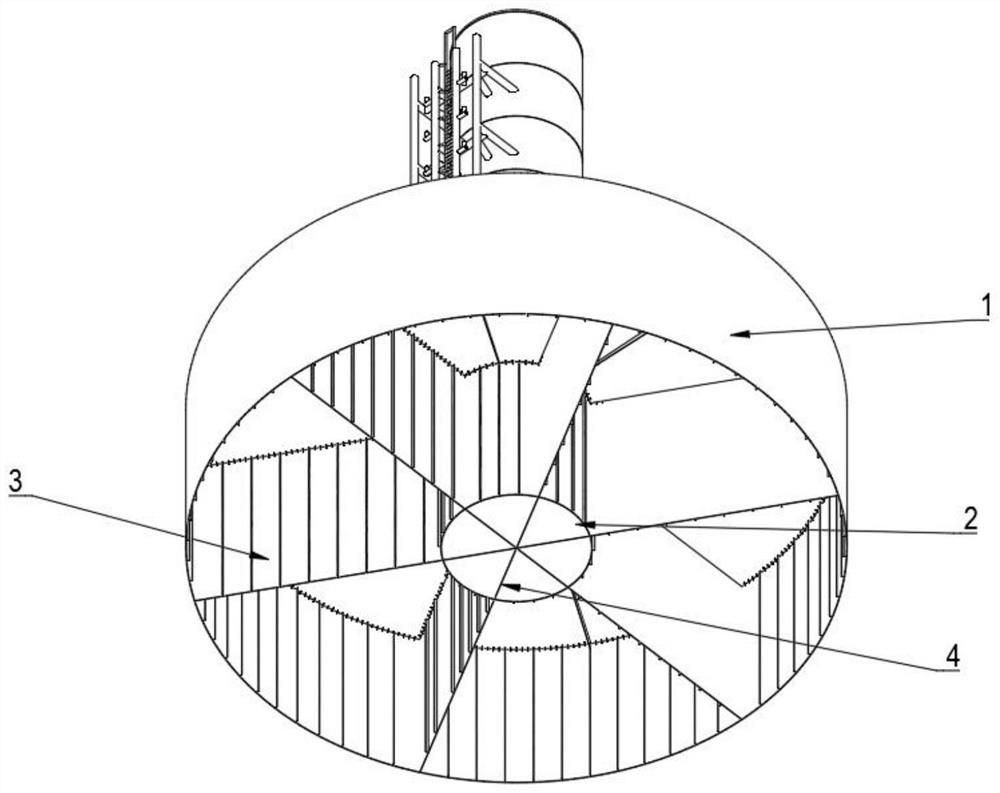

[0025] like Figure 1-5 As shown, the present invention is an unsupported single-column composite cylindrical foundation for offshore wind turbines, comprising: a thin-walled outer cylinder 1, a thin-walled inner cylinder 2 arranged at the center of the inner cavity of the thin-walled outer cylinder 1, On the outer cylinder 1, a single-column transition section 7 for connecting with the fan tower is arranged between the thin-walled outer cylinder 1 and the single-column transition section 7, a conical variable-diameter force transmission structure 6 for transmitting loads, and The reinforcing cylinder 10 outside the thin-walled outer cylinder 1; wherein, the cavity between the thin-walled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com