Door and window heat insulation strip with good sealing effect and heat insulation method of door and window heat insulation strip

A technology of sealing effect and sealing strip, applied in windows/doors, buildings, building components, etc., can solve the problems of entering the room, poor sealing effect of heat insulation strips, affecting sound insulation and wind resistance of doors and windows, and achieving sealing and heat insulation performance Good, light weight, high-efficiency sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

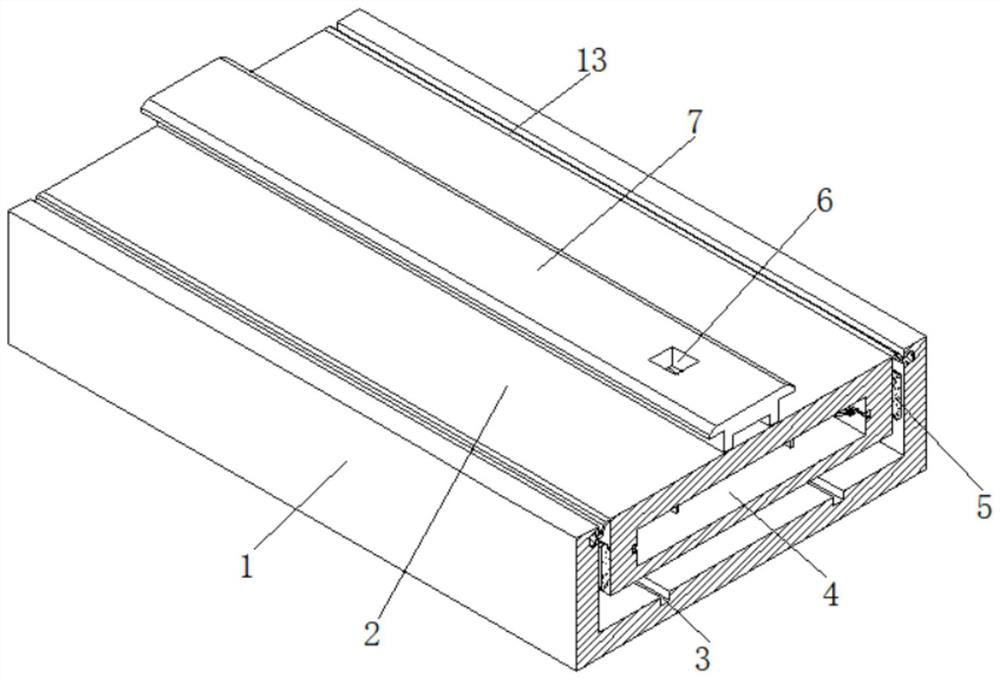

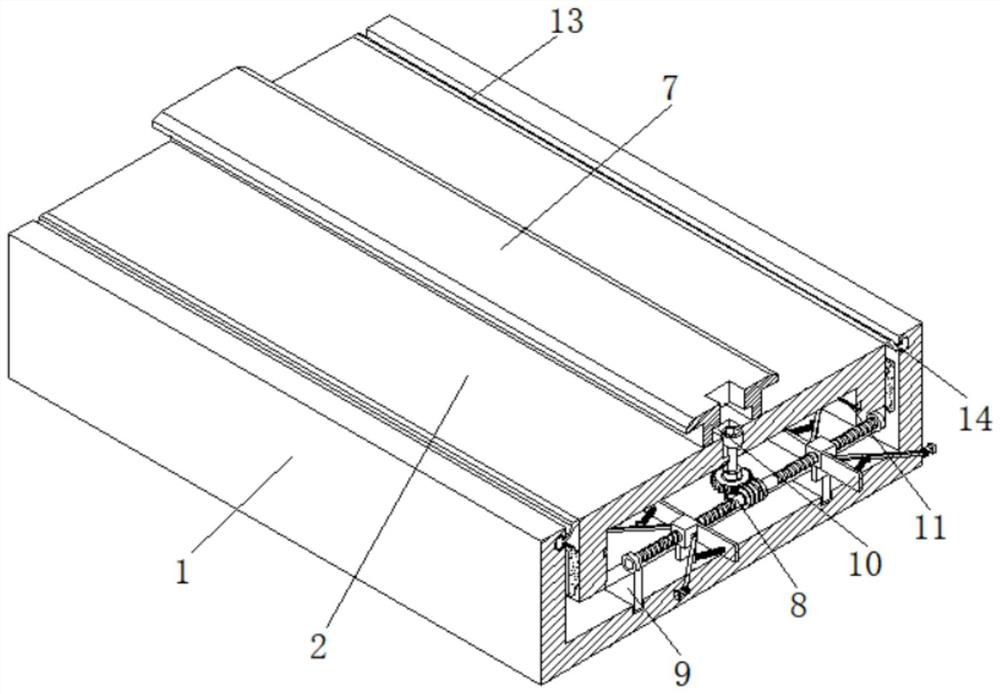

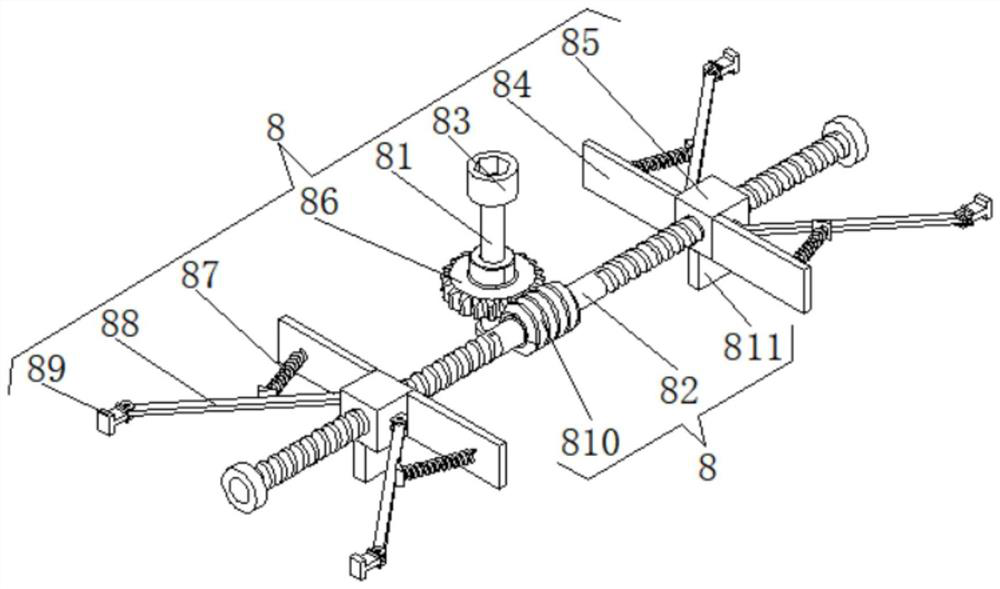

[0025] A door and window heat insulation strip with good sealing effect comprises an installation frame 1. The tops of the left and right sides of the inner cavity of the installation frame 1 are provided with first sealing grooves 14. By using the first sealing grooves 14, the sealing strip 13 The snap-fit installation is performed to prevent the sealing strip body 2 from falling off the interior of the installation frame 1. The left and right sides of the bottom of the inner cavity of the installation frame 1 are provided with second sealing grooves 3, and the inner cavity of the installation frame 1 is provided with the sealing strip body 2. The sealing strips 13 are fixedly installed on the tops of the left and right sides of the sealing strip body 2, and the movable sealing blocks 5 are fixedly connected to the left and right sides of the sealing strip body 2. The sealing strips 13 extend away from the sealing strip body 2 to the first side. The inner cavity of a sealing...

Embodiment 2

[0033] A door and window heat insulation strip with good sealing effect comprises an installation frame 1. The tops of the left and right sides of the inner cavity of the installation frame 1 are provided with first sealing grooves 14. By using the first sealing grooves 14, the sealing strip 13 The snap-fit installation is performed to prevent the sealing strip body 2 from falling off the interior of the installation frame 1. The left and right sides of the bottom of the inner cavity of the installation frame 1 are provided with second sealing grooves 3, and the inner cavity of the installation frame 1 is provided with the sealing strip body 2. The sealing strips 13 are fixedly installed on the tops of the left and right sides of the sealing strip body 2, and the movable sealing blocks 5 are fixedly connected to the left and right sides of the sealing strip body 2. The sealing strips 13 extend away from the sealing strip body 2 to the first side. The inner cavity of a sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com