Construction method of large-span wood truss roof

A construction method and technology of wooden trusses, which are applied in the processing of building materials, construction, building structure, etc., can solve the problems of inconvenience in the construction of large-span wooden truss roofs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

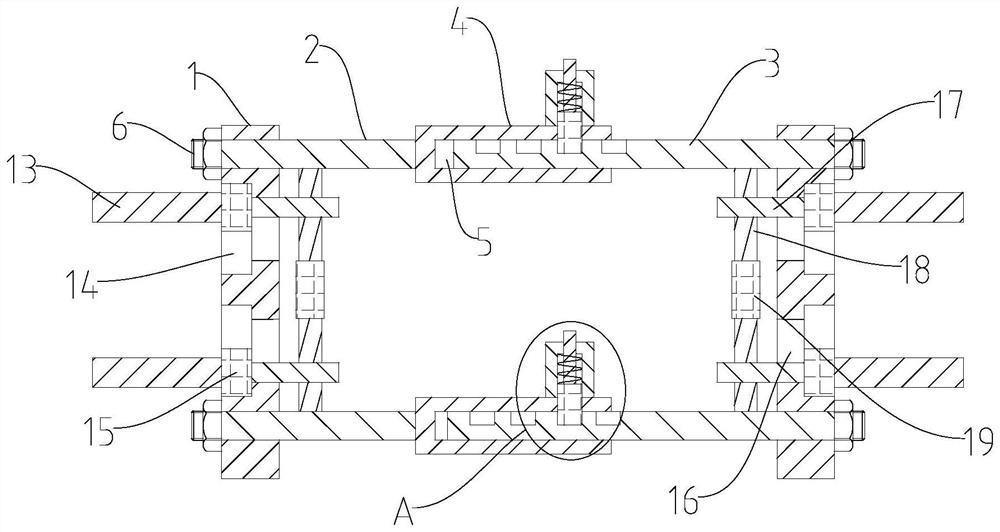

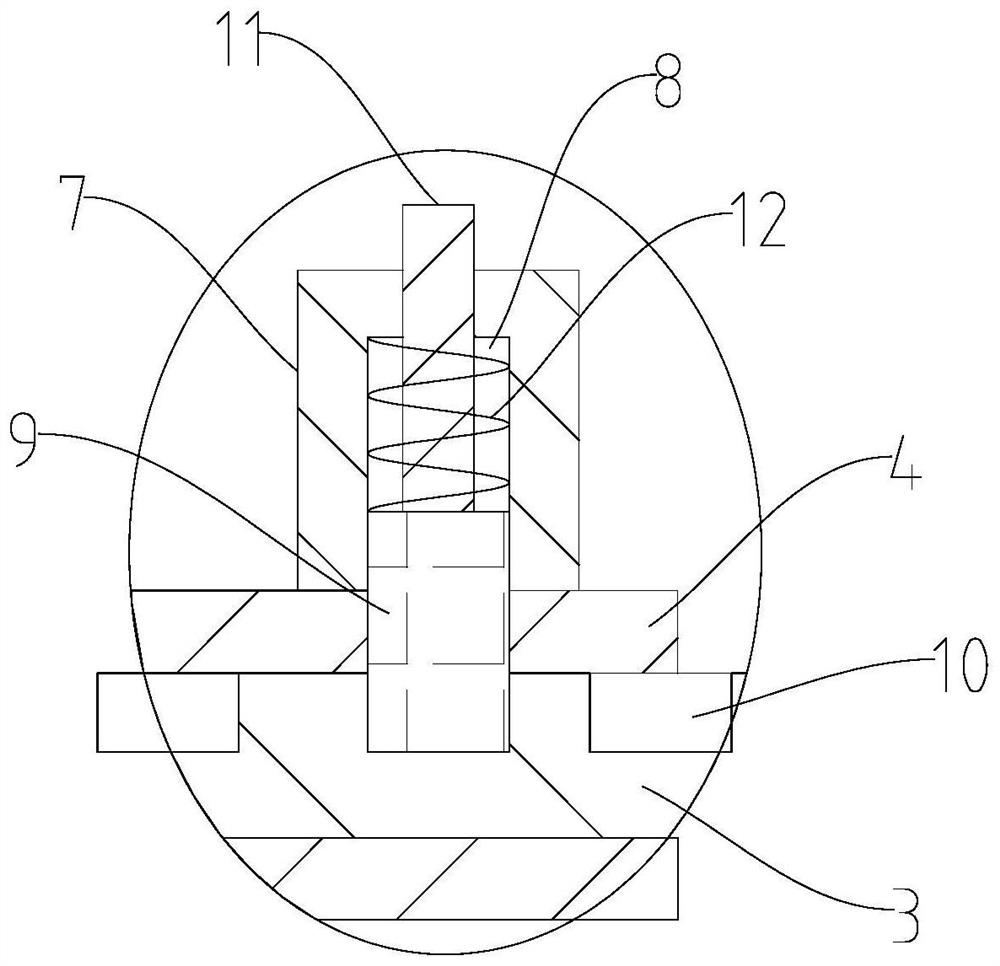

[0022] The technical solutions in the present invention will be further described below with reference to the accompanying drawings and embodiments.

[0023] like figure 1 As shown, the embodiment of the present invention proposes a construction method for a large-span wooden truss roof, which includes the following steps:

[0024] S1. BIM simulation analysis: build a model through BIM, analyze the whole truss, node connection, and construction work surface; optimize the node connection method; S2, assembly: pre-assemble the parts of the wooden truss in the factory, and then transport it to Construction site; S3, assembled tire frame setting: set up assembled tire frame at the construction site; S4, wood truss ground assembly: process the factory pre-assembled truss on the on-site ground assembled tire frame to become a whole truss; S5, first truss Truss hoisting and installation: use hoisting equipment to hoist the first wood truss, and weld the wood truss to the structural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com