Roof steel net rack for building

A technology for steel grids and buildings, which is applied to buildings, building components, building structures, etc., can solve problems such as height difference, inability to adjust distances, waste of time, etc., to avoid deformation, connect securely, and reduce distance changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

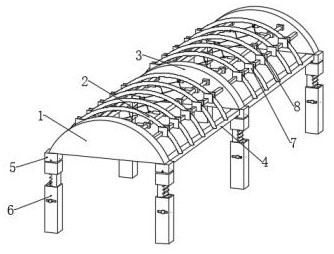

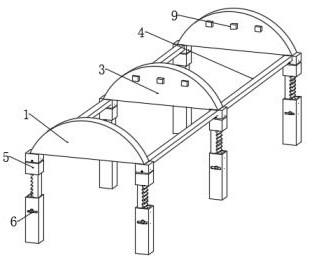

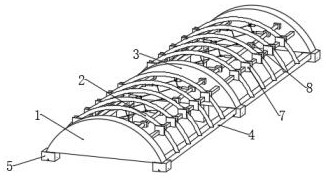

[0032] like Figure 1-8As shown, a roof steel grid frame for construction includes a first fixing frame 1, a first fixing beam 2, a second fixing frame 3 and a second fixing beam 4, and the second fixing beam 4 is arranged on the first fixing frame 1 and the second fixing beam 4. The first fixed beams 2 are welded between the second fixed frames 3 and between the second fixed beams 4. The two ends of the first fixed frame 1 and the second fixed frame 3 are provided with a compensation structure 5 and a lifting structure 6. The compensation structure 5 is connected with both ends of the first fixing frame 1, the lifting structure 6 is welded to the bottom end of the compensation structure 5, a first connecting block 9 is arranged between the first fixing frame 1 and the second fixing frame 3, and the first fixing frame 5 is A connecting structure 8 is provided between the frame 1 and the second fixing frame 3, and both ends of the connecting structure 8 are connected with the f...

Embodiment 2

[0034] like Figure 4-5 As shown, the compensation structure 5 includes a second connecting block 501, a first fixing groove 502, a compensation block 503, a first reserved groove 504, a first telescopic spring 505, a first connecting rod 506, a second connecting rod 507, a second The telescopic spring 508, the second fixing groove 509, the middle block 510, the second connecting block 501 is welded on both ends of the first fixing frame 1 and the second fixing frame 3, the middle block 510 is arranged inside the second connecting block 501, the middle The inside of the block 510 is provided with a first fixing slot 502, the top of the lifting structure 6 is provided with a compensation block 503, the compensation block 503 is arranged inside the first fixing slot 502, the second fixing slot 509 and the first reserved slot 504 are arranged in the compensation block 503. Inside the block 503 , the first connecting rod 506 is disposed inside the first reserved groove 504 , the f...

Embodiment 3

[0036] like Figure 4 and Image 6 As shown, the lifting structure 6 includes a third connecting block 601, a connecting bar 602, a clamping groove 603, a connecting column 604, a clamping column 605, a clamping bar 606, a third telescopic spring 607, a third connecting rod 608, a third The fixing slot 609 and the second reserved slot 610, the third connecting block 601 is connected with the connecting bar 602, the clamping slot 603 is arranged on the side wall of the connecting bar 602, the third fixing slot 609 is opened in the interior of the connecting column 604, and The connecting bar 602 is located inside the third fixing groove 609 of the connecting column 604, the second reserved groove 610 is opened on both sides of the connecting column 604, and the clamping column 605 is arranged inside the second reserved groove 610, and the clamping column 605 is welded with the clamping bar 606, the third connecting rod 608 is arranged inside the clamping bar 606, and the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com