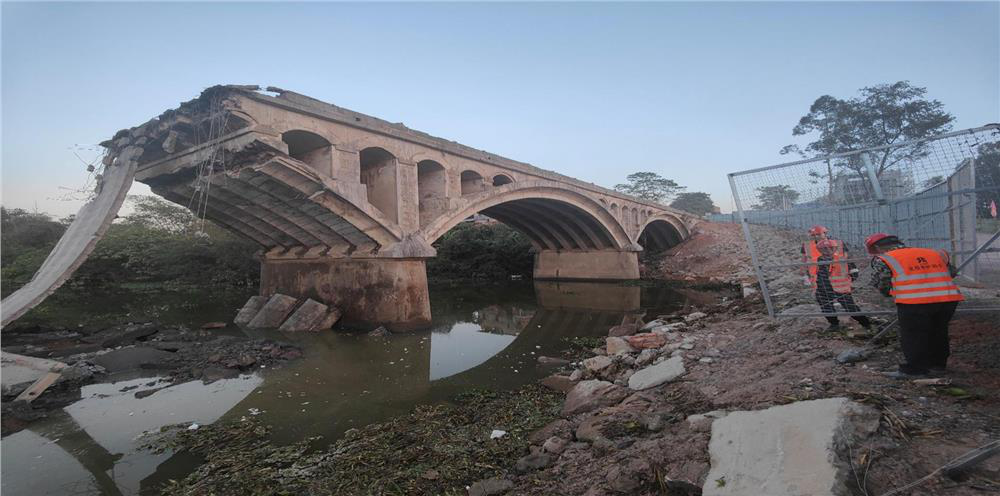

Construction method for quickly breaking and dismantling masonry arch bridge based on bridge floor cutting

A technology for masonry arch bridges and construction methods, which is applied in construction, building maintenance, building construction, etc., can solve the problems of prolonged construction period, high cost, heavy workload, etc., and achieves short demolition construction period, low vibration and less dust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] The construction method for rapid demolition of masonry arch bridges based on bridge deck cutting includes the following steps:

[0064] Step 1: Collect or actually measure the structural parameters of the masonry arch bridge to be demolished, and obtain the span, sag height, deck pavement thickness, width and reinforcement arrangement;

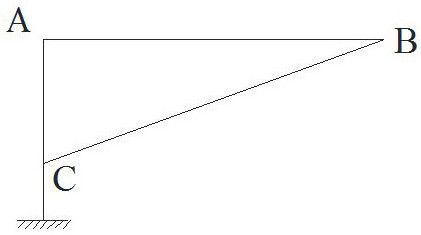

[0065] Step 2, cutting the deck of the masonry arch bridge to be demolished, and the cutting position at least includes the deck pavement directly above the arch foot of one side;

[0066] Step 3: Use the long-arm hook machine to break down the arch foot of the other side of the masonry arch bridge, and the span of the masonry arch bridge will collapse and fall as a whole;

[0067] The fourth step is to clear and transport the fallen masonry materials, and complete the demolition of the masonry arch bridge.

[0068] In step 2, cutting the deck of the masonry arch bridge to be demolished is mainly to cut the steel bars paved on the dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com