Multifunctional bridge erecting machine and bridge erecting construction method

A bridge erecting machine, multi-functional technology, applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of inconvenient counterweight and affecting construction efficiency, and achieve the effect of small space occupation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

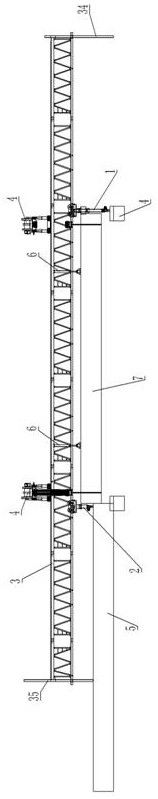

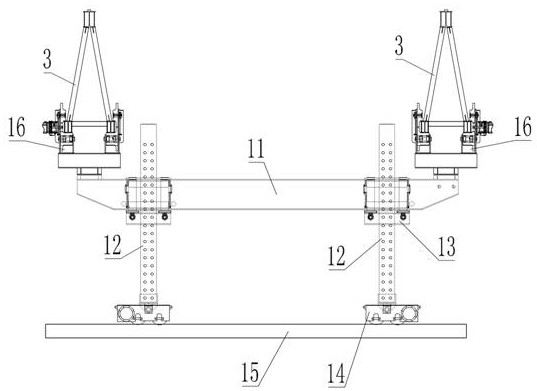

[0054] A multifunctional bridge erecting machine, see Figure 1 to Figure 10 .

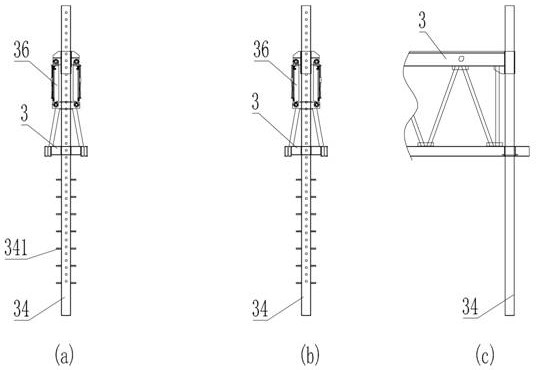

[0055] like figure 1 As shown, the multifunctional bridge erecting machine includes a front support device 1 and a rear support device 2. The bottom of the front support device 1 and the rear support device 2 are respectively provided with a walking mechanism that can move left and right on the track. The front support device and the rear support device Two longitudinal main load-bearing beams 3 are arranged at the upper interval, and two front and rear lifting cranes 4 are arranged on the main load-bearing beams 3 . The front support device 1 and the rear support device 2 play the role of supporting the main load-bearing beam 3, and the front support device 1 and the rear support device 2 can drive the main load-bearing beam 3 to move left and right, that is, move laterally; figure 2 As shown, from the end-side perspective, the main load-bearing beam 3 is in the shape of a triangle as a whole,...

Embodiment 2

[0074] The embodiment of the present invention also provides a bridge erection construction method, the construction method adopts the multifunctional bridge erection machine in Embodiment 1, and specifically includes the following steps:

[0075] (1) The bridge erection machine is arranged in place:

[0076] (1.1) Combination figure 1 As shown, transverse rails are arranged on the built bridge pier 4 and on the bridge built section 5, and the track is arranged in a position so that the bridge erection machine can hoist and move the prefabricated beam 7 on the corresponding bridge pier by the lifting crane 4.

[0077] (1.2) Set the front support device 1 and the rear support device 2 on the corresponding rails.

[0078] When the bridge erection machine is initially arranged, the front support device 1 and the rear support device 2 are installed by means of a crane.

[0079] (1.3) Fix the two main load-bearing beams 3 on both sides of the top of the front support device 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com