Tire cord steel inclusion plasticization control method and tire cord steel

A control method and inclusion technology, which are applied in the field of cord steel and cord steel inclusion plasticization control, can solve the problems of poor deformation ability of inclusions, narrow industrial production control window, and difficult control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0055] A method for controlling the plasticization of inclusions in cord steel, comprising the following steps:

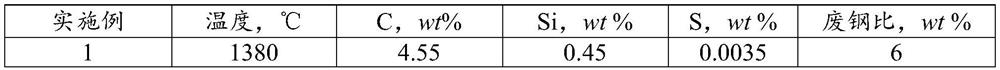

[0056] Step 1. KR molten iron pretreatment: molten iron is transported to KR for desulfurization treatment, and the parameters of molten iron after desulfurization are shown in Table 1 (ie, the parameters of molten iron entering the converter).

[0057] Step 2. Smelting:

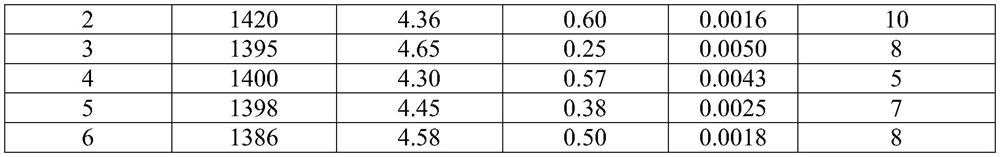

[0058] The 135t converter is used for smelting, and the conditions of molten iron, scrap steel and end point control in the converter are shown in Table 1 and Table 2.

[0059] Table 1 The molten iron conditions and scrap ratio of the converter into the furnace

[0060]

[0061]

[0062] Table 2 Control situation of converter tapping end point

[0063] Example End point temperature, °C End point carbon, % End point oxygen, % End point P, % End point S, % 1 1665 0.068 0.042 0.014 0.0085 2 1650 0.083 0.035 0.012 0.0100 3 1698 0.073 0.049 0.011 0...

Embodiment 7-12

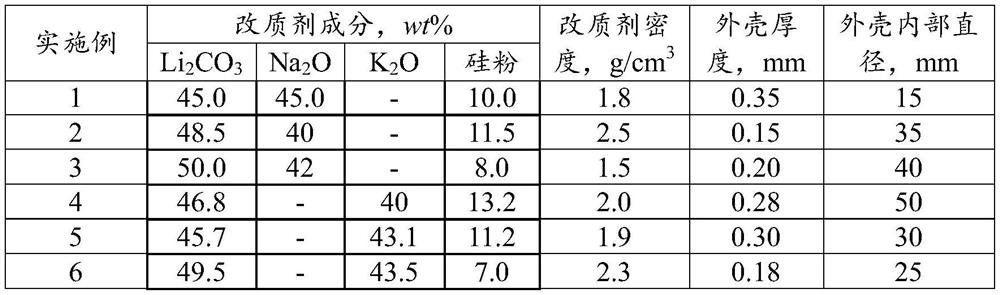

[0083] A method for controlling the plasticization of inclusions in cord steel, comprising the following steps:

[0084] Step 1. KR molten iron pretreatment: molten iron is transported to KR for desulfurization treatment, and the parameters of molten iron after desulfurization are shown in Table 1 (ie, the parameters of molten iron entering the converter).

[0085] Step 2. Smelting:

[0086]The 100t electric furnace is used for smelting, and the conditions of molten iron, scrap steel and end point control in the electric furnace are shown in Tables 8 and 9.

[0087] Table 8 The molten iron conditions and scrap ratio of the electric furnace into the furnace

[0088] Example temperature, °C C,% Si, % S,% Scrap ratio, % 7 1390 4.50 0.25 0.0025 6 8 1410 4.46 0.60 0.0026 5 9 1380 4.61 0.37 0.0015 10 10 1405 4.30 0.55 0.0037 8 11 1396 4.65 0.39 0.0017 9 12 1385 4.56 0.45 0.0021 7

[0089] Table 9 Control si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com