Process and system for recycling phenol water in coal gas producer by gasifying and feeding phenol water into furnace

A technology of gas generator and water vapor, which is applied in the field of coal chemical industry, can solve the problems of high operating cost, large energy consumption, and large investment at one time, and achieve the effect of long service life of equipment, reduction of cooling water consumption, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

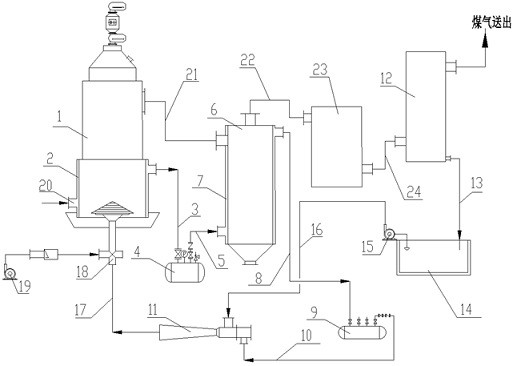

[0016] figure 1 As shown, the gas generator phenol water vaporization into the furnace reuse system includes a gas generator 1, a steam drum 4, a cyclone 6, a superheater 7, a sub-cylinder 9, a steam injection desuperheater 11, an intercooler 12, Phenol pool 14 and phenol water pump 15. The lower part of the gas generator 1 is provided with a vaporization cooling device 2; the vaporization cooling device 2 adopts a sandwich type, and is provided with a softened water inlet 20 and a saturated steam outlet, and the softened water enters the vaporization cooling device 2 through the softened water inlet 20. The furnace 1 is cooled and vaporized into saturated steam, and then flows out of the vaporization cooling device 2 from the saturated steam outlet. The saturated steam outlet of the vaporization cooling device 2 communicates with the steam drum 4 through the first saturated steam pipe 3, and the steam drum 4 communicates with the steam inlet of the superheater 7 formed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com