Carbon-based phase change energy storage material for solar direct photo-thermal conversion and preparation method of carbon-based phase change energy storage material

A phase-change energy storage material and technology of phase-change materials, applied in the field of carbon-based phase-change energy storage materials and their preparation, can solve the problems of inability to have both light-to-heat conversion efficiency and high thermal conductivity to prevent liquid leakage, and achieve excellent anti-corrosion Liquid leakage ability, highlighting the effect of light-to-heat conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A novel photothermal conversion phase change energy storage material, the preparation method of which is as follows:

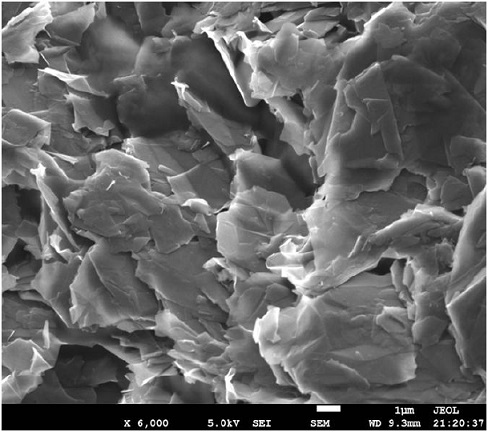

[0045]Step 1: Immerse the carbon-based high thermal conductivity porous material (specifically, expanded graphite) in a completely melted organic phase change material (specifically, paraffin (C 35 H 72 )), placed in a vacuum oven with a vacuum degree of -0.05MPa, the vacuum impregnation time was set to 8h, and the impregnation temperature was set to 20°C above the phase transition point of the organic phase change energy storage material; in this step, Carbon-based high thermal conductivity porous materials will significantly improve the thermophysical properties and liquid leakage resistance of pure organic phase change energy storage materials due to their inherent microporous structure and high thermal conductivity; the quality of carbon-based high thermal conductivity porous materials and organic phase change materials The percentage is 25:75;

...

Embodiment 2

[0055] According to Example 1, the difference is that the mass ratio between the phase change matrix, the carbon-based high thermal conductivity porous material and the carbon-based photothermal conversion enhancer is different, and the mass percentage of the carbon-based high thermal conductivity porous material and the organic phase change material is different. is 25:75, and the mass percentage of the thermally conductive enhanced phase change material particles and the carbon-based photothermal conversion enhancer is 85:15.

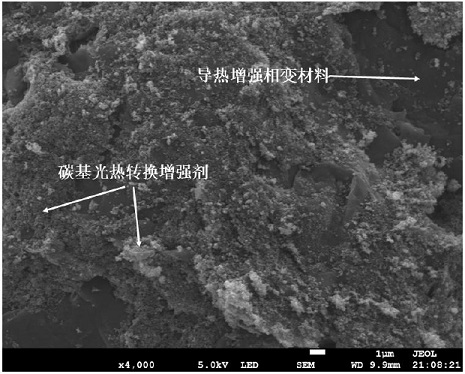

[0056] The scanning electron microscope image of the obtained carbon-based phase change energy storage material is as follows image 3 As shown, it can be seen that with the increase of the quality of the carbon-based photothermal conversion enhancer, the coating amount of the carbon-based photothermal conversion enhancer on the surface of the thermal conductivity enhanced phase change material particles increases to a certain extent.

[0057] The the...

Embodiment 3

[0060] According to Example 1, the difference is that the mass ratio between the phase change matrix, the carbon-based high thermal conductivity porous material and the carbon-based photothermal conversion enhancer is different, and the mass percentage of the carbon-based high thermal conductivity porous material and the organic phase change material is different. is 25:75, and the mass percentage of the thermally conductive enhanced phase change material particles and the carbon-based photothermal conversion enhancer is 80:20.

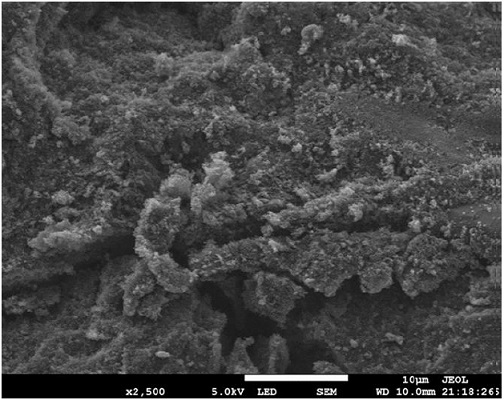

[0061] The scanning electron microscope image of the obtained carbon-based phase change energy storage material is as follows Figure 4 As shown, it can be seen that with the continuous increase of the quality of the carbon-based photothermal conversion enhancer, the coating amount of the carbon-based photothermal conversion enhancer on the surface of the thermally conductive enhanced phase change material particles also continues to increase.

[0062...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com