High-performance warm-mixed special asphalt based on hot in-place recycling and mixture of high-performance warm-mixed special asphalt

A kind of asphalt mixture, high-performance technology, applied in building insulation materials, building components, buildings, etc., can solve the problem of affecting the road performance and durability of recycled mixture, limiting the road performance and durability of recycled mixture, affecting the improvement The treatment effect of permanent asphalt pavement and other issues, to achieve excellent road performance, improve the bonding strength and mechanical properties, improve the effect of physical and chemical adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A high-performance warm-mix special asphalt based on hot-in-place regeneration is prepared by the following methods:

[0053] 1) Heat the 130# base asphalt to 150°C, add 2% SBS modifier and 2% SBR modifier, and stir well for 20min;

[0054] 2) Adjust the temperature to 175°C, slowly add 1% EVA, 0.3% silane coupling agent, 0.3% anti-stripping agent, place the sample under the shearing machine, adjust the speed of the shearing machine to 4500 r / min, and keep shearing for 1 h. There are no obvious particles on the asphalt surface.

[0055] 3) Add 0.20% stabilizer, move the sample to the mixer, stir and develop at 175°C for 0.5h, then add 4% high-permeability warm regenerant, and continue stirring for 0.5h to obtain a high-performance heat-in-place regeneration Warm mix special asphalt.

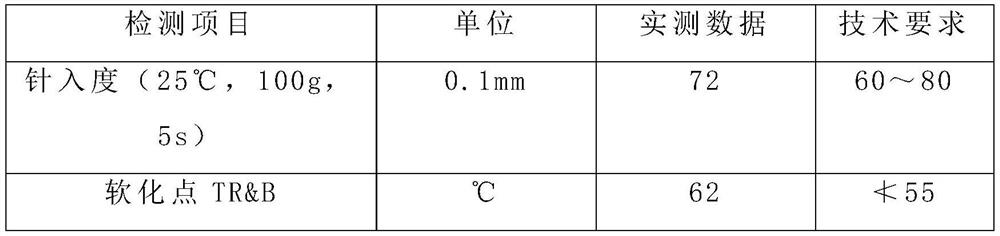

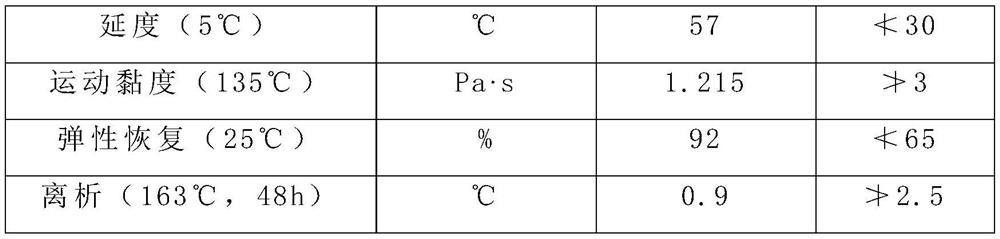

[0056] Table 1 Technical Specifications of High Performance Warm Mix Special Asphalt (I-C)

[0057]

[0058]

[0059] A high-performance warm-mix special asphalt mixture based on ...

Embodiment 2

[0066] A high-performance warm-mix special asphalt based on hot-in-place regeneration is prepared by the following methods:

[0067] 1) Heat the 130# base asphalt to 150°C, add 4% SBS modifier and 1% SBR modifier, and stir well for 20min;

[0068] 2) Adjust the temperature to 175°C, slowly add 1% EVA, 0.3% silane coupling agent, 0.3% anti-stripping agent, place the sample under the shearing machine, adjust the speed of the shearing machine to 4500 r / min, and keep shearing for 1 h. There are no obvious particles on the asphalt surface.

[0069] 3) Add 0.24% stabilizer, move the sample to the mixer, stir at 175°C for 0.5h, then add 6% high-permeability warm regenerant, and continue to stir for 0.5h, to obtain a high-performance heat-in-place regeneration Warm mix special asphalt.

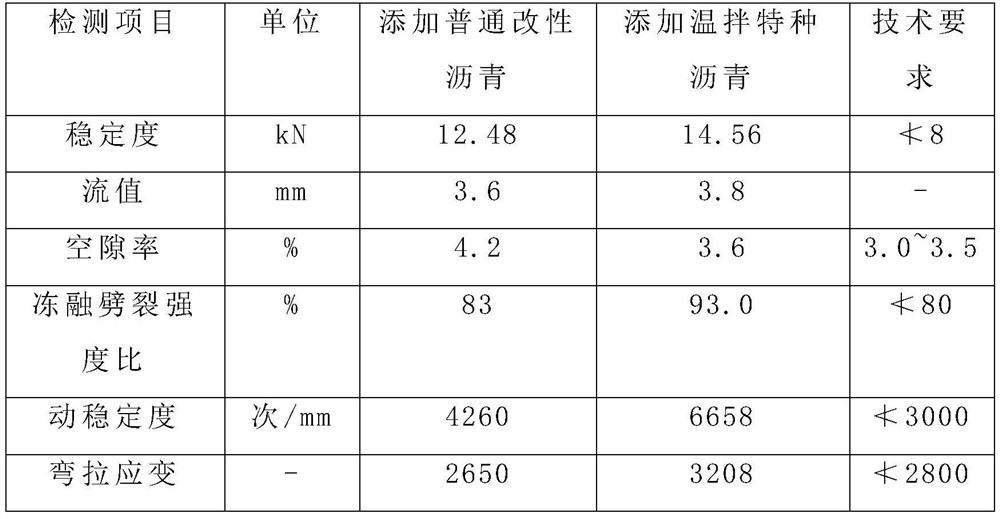

[0070] Table 3 Technical indicators of high performance warm mix special asphalt (I-C)

[0071]

[0072] A high-performance warm-mix special asphalt mixture based on hot-in-place regeneration, i...

Embodiment 3

[0080] A high-performance warm-mix special asphalt based on hot-in-place regeneration is prepared by the following methods:

[0081] 1) Heat the 110# base asphalt to 150°C, add 3% SBS modifier and 1% SBR modifier, and stir fully for 20min;

[0082] 2) Adjust the temperature to 175°C, slowly add 1% EVA, 0.6% silane coupling agent, 0.6% anti-stripping agent, place the sample under the shearing machine, adjust the speed of the shearing machine to 4500r / min, and keep shearing for 1h. There are no obvious particles on the asphalt surface.

[0083] 3) Add 0.20% stabilizer, move the sample to the mixer, stir at 175°C for 0.5h, then add 8% high-permeability warm regenerant, and continue to stir for 0.5h, to obtain a high-performance heat-in-place regeneration Warm mix special asphalt.

[0084] Table 5 Technical indicators of high performance warm mix special asphalt (I-C)

[0085]

[0086] A high-performance warm-mix special asphalt mixture based on hot-in-place regeneration, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com