Controllable magnetic circuit permanent magnet suspension carrier roller

A magnetic levitation and idler technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve problems such as spending a lot of time, affecting product quality, and material pulling and deforming, achieving rapid replacement and avoiding time costs. Increase and avoid the effect of high friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make it easy to understand the technical means, creation features, achieved goals and effects of the present invention, the present invention will be further described below with reference to the specific embodiments.

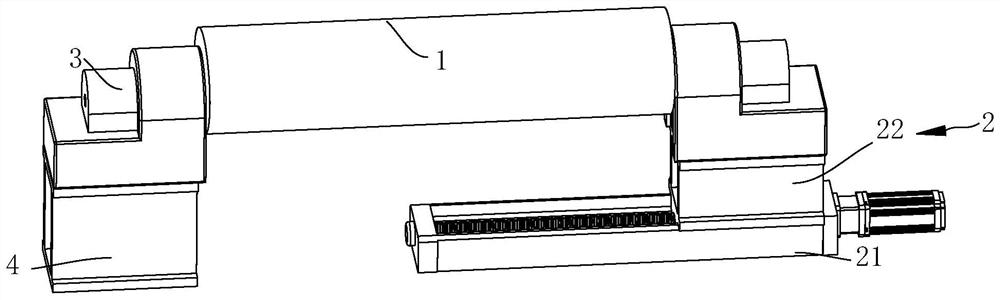

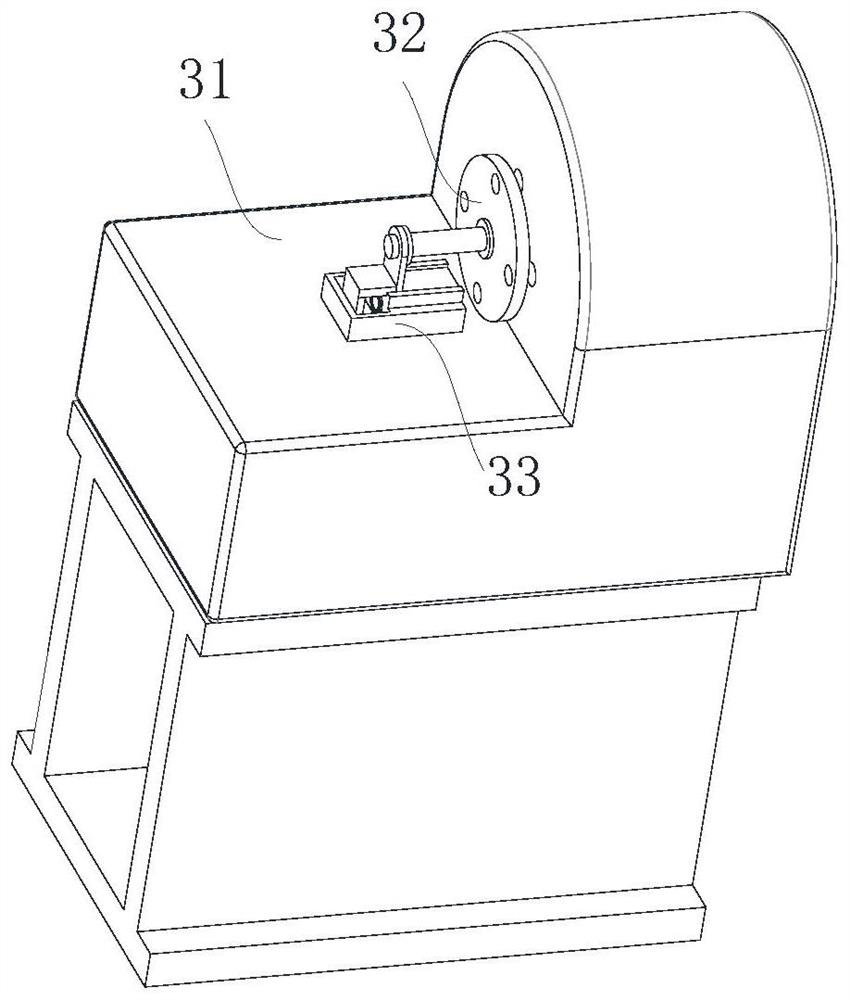

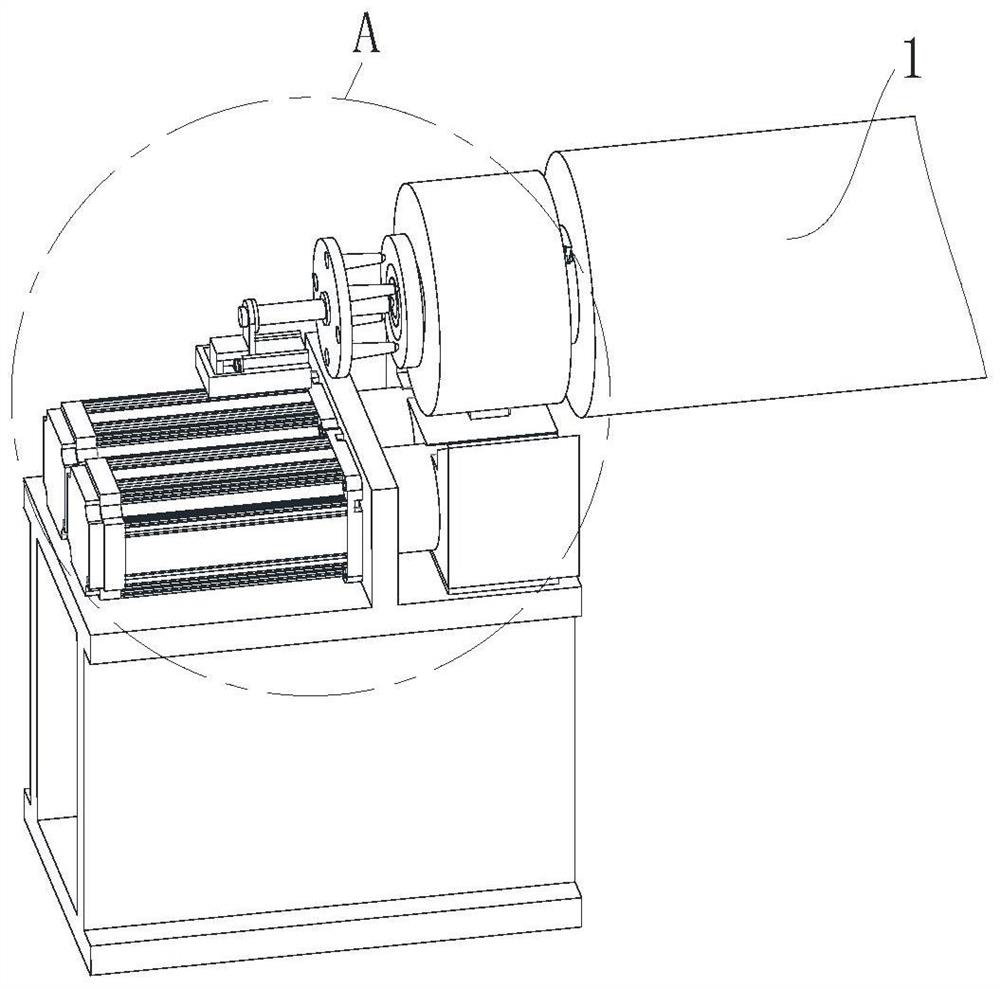

[0037] like Figure 1-Figure 14 As shown in the figure, a controllable magnetic circuit permanent magnet suspension idler according to the present invention includes an idler 1, a sliding mounting seat assembly 2, a magnetic suspension assembly 3 and a fixed mounting seat 4. The fixed mounting seat 4 and the sliding mounting seat assembly A magnetic suspension assembly 3 is installed on the 2, and the magnetic suspension assemblies 3 at both ends are on the same axis, and an idler 5 is installed between the magnetic suspension assemblies 3 at both ends;

[0038] As an embodiment of the present invention, such as Figure 4-Figure 8As shown, the magnetic suspension assembly 3 includes a radial permanent magnet assembly 34 fixed on the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com