Oil suspension type air cylinder seat bearing structure

A load-bearing structure and cylinder block technology, applied in the field of cylinder blocks of compressors, can solve problems such as high strength requirements for cylinder blocks, easy wear, and reduced reliability of compressors, so as to avoid high-strength friction, reduce contact area, Effect of reducing frictional power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

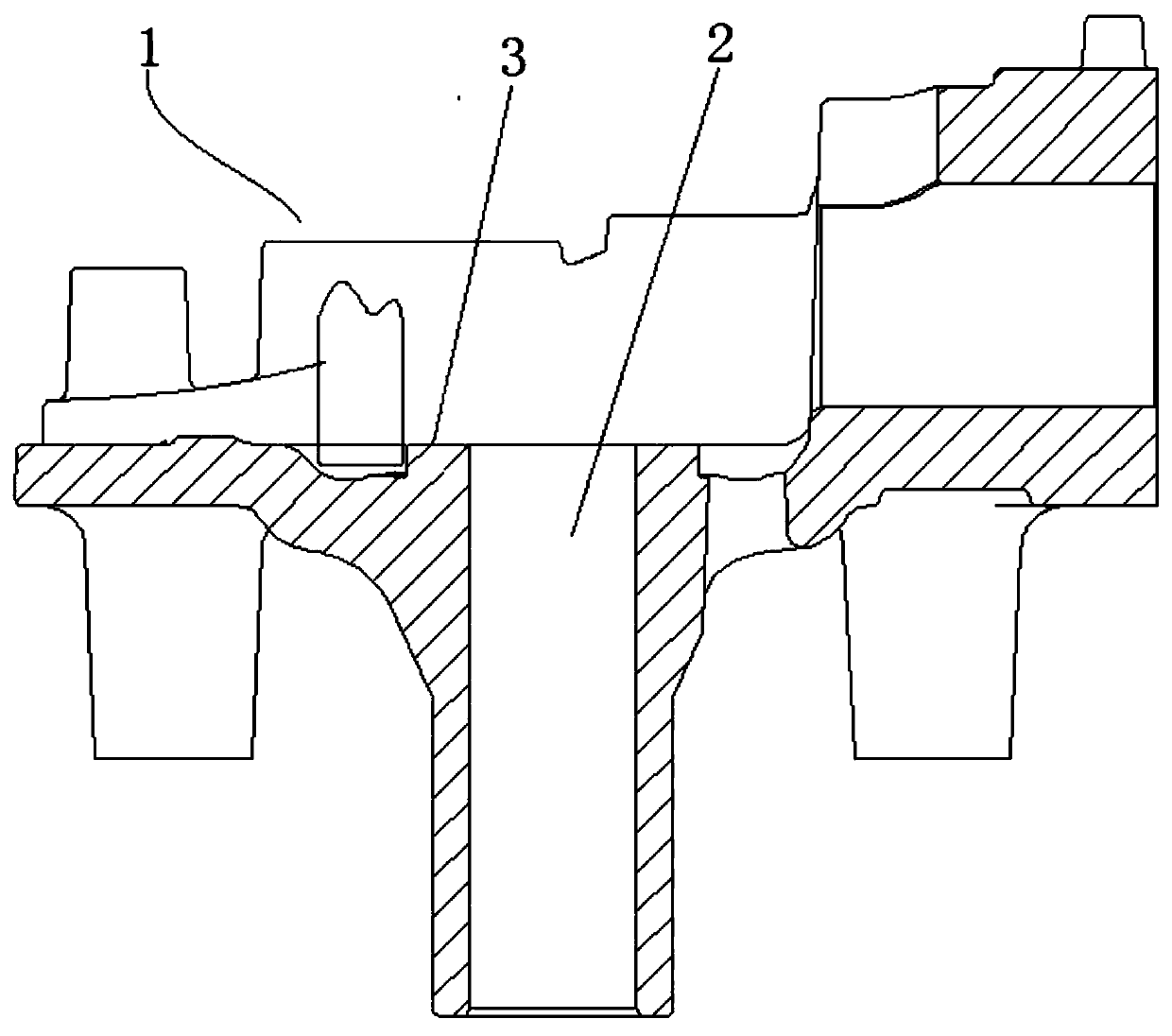

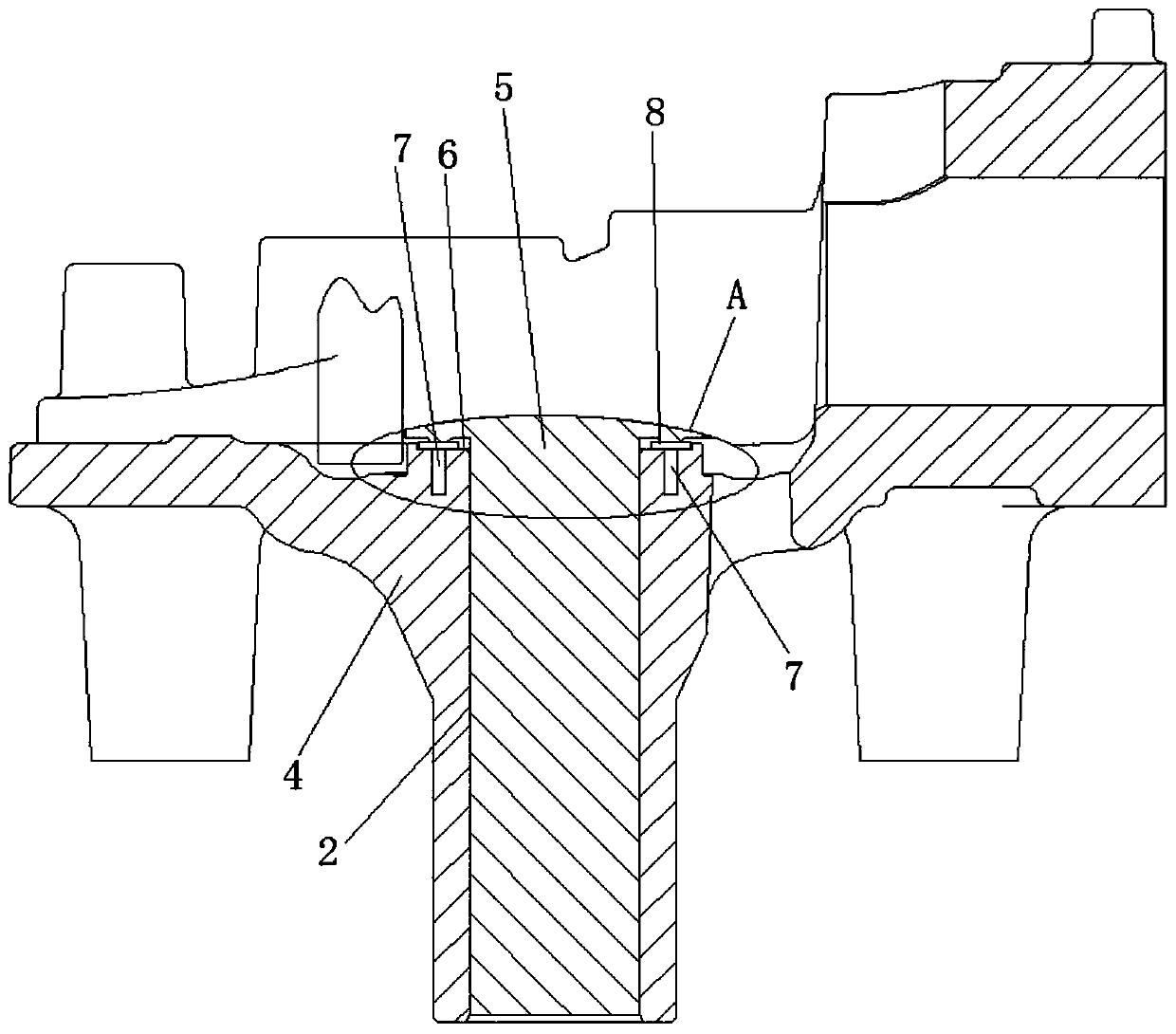

[0036] Such as Figure 2 ~ Figure 4 As shown, an oil-suspended cylinder block bearing structure includes a cylinder block support 4 and a crankshaft hole 2. A crankshaft 5 is provided in the crankshaft hole 2, and the lower end surface of the shoulder of the crankshaft 5 and the cylinder block support 4 A suspension bearing structure is formed between the upper end surfaces of the bearing structure, the bearing structure includes a stepped groove 6 provided on the upper end surface, and an oil groove 7 is provided in the stepped groove 6 along the axial direction of the cylinder seat support 4; The oil groove 7 is provided with oil; the lower end surface of the shoulder of the crankshaft 5 is provided with a lower protrusion 9 corresponding to the oil groove 7; a thrust pad is provided between the lower protrusion 9 and the oil groove 7 Sheet 8; the radial cross-sectional width of the thrust washer 8 is greater than the width of the oil groove 7.

[0037] In this embodiment, the...

Embodiment 2

[0052] The difference between this embodiment and the first embodiment is that the arrangement structure of the oil groove is different.

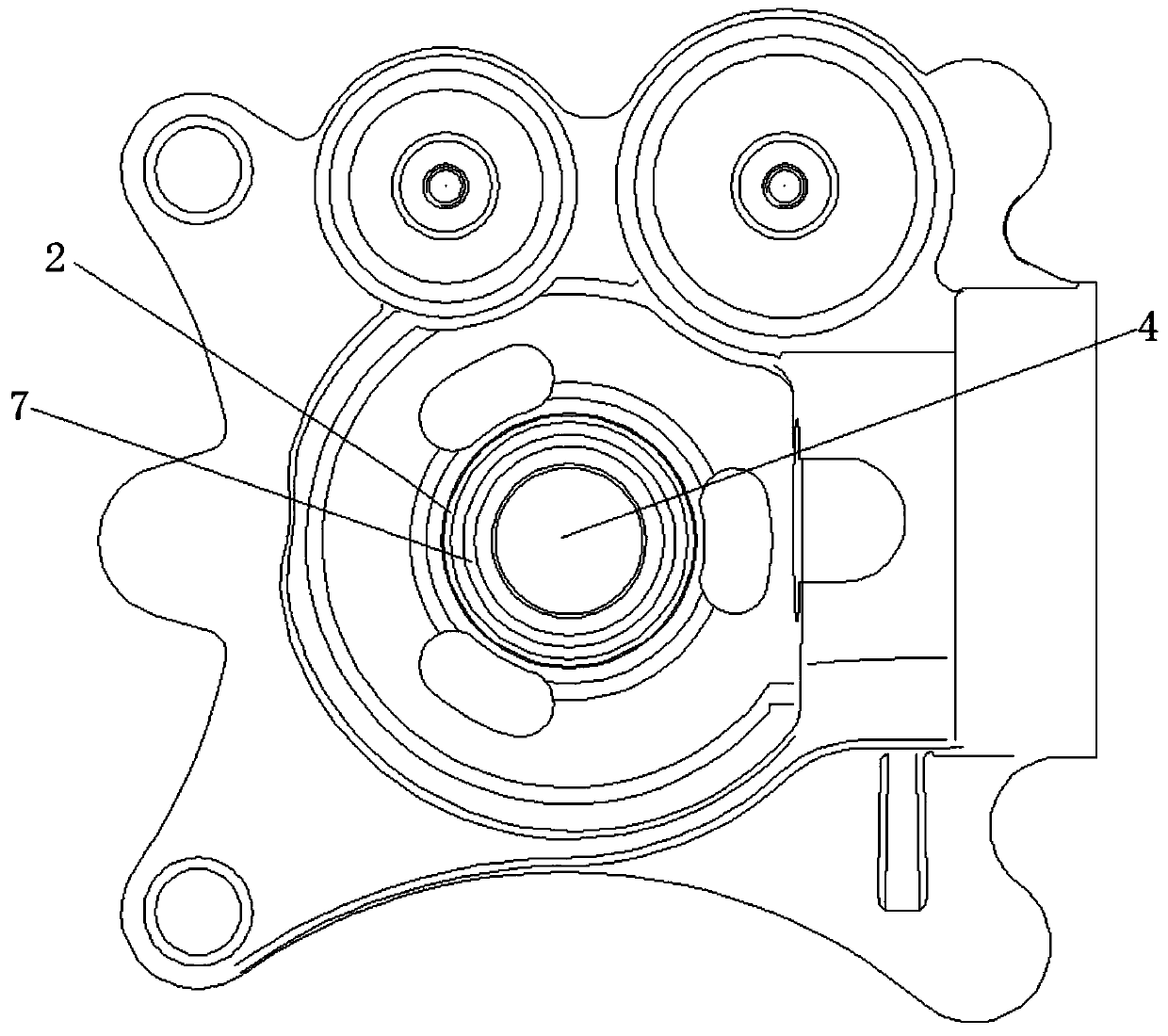

[0053] Specific, such as Figure 5 As shown, an oil-suspended cylinder block bearing structure includes a cylinder block support 4 and a crankshaft hole 2. The cylinder block support 4 is provided with a stepped groove 6 near the crankshaft hole 2, and the stepped groove 6 extends from the inside to the outside. A low second step 602 and a high first step 601 are provided. The first step 602 is evenly provided with six oil grooves 7 along the circumferential direction; the oil groove 7 is provided with oil; the oil groove 7 is arc-shaped The groove has a depth of 2mm in the axial direction.

[0054] When working, set the crankshaft in the crankshaft hole, and set a thrust washer above the oil groove; during the movement of the crankshaft, the crankshaft and the cylinder block support are always in the state of oil lubrication and oil contact, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com