Salvage system and method for cooperatively treating water surface garbage through unmanned aerial vehicle and unmanned ship

A technology for surface garbage and co-processing, which is used in open water surface cleaning, grain processing, motor vehicles, etc., can solve the problems of reducing the amount of surface garbage, increasing labor costs, time-consuming, etc., and achieves improved stability, improved buoyancy, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

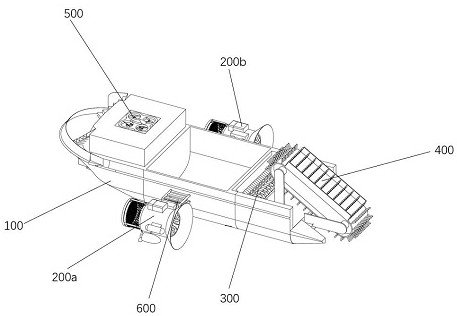

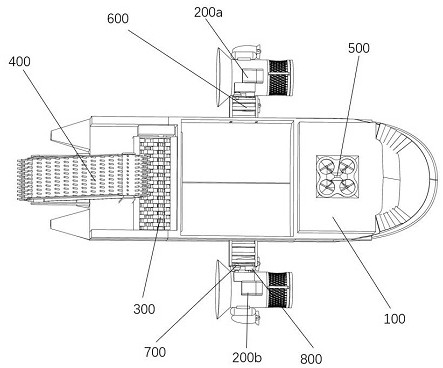

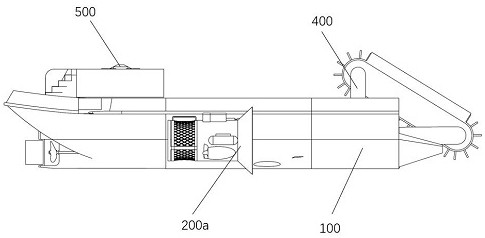

[0051] The present invention provides a salvage system for cooperating with unmanned aerial vehicles and unmanned ships to deal with surface garbage, such as figure 1 As shown, the system includes a mother ship (100) and a garbage salvaging device (400) on the mother ship (100), a garbage rolling device (300), a drone charging bay (103), and on both sides of the mother ship (100) A child ship (200), wherein the first child ship (200a) is located on the right side of the mother ship (100), and the second child ship (200b) is located on the left side of the mother ship (100); the garbage salvage device (400), the garbage grinding The pressure device (300), the main ship garbage storage compartment (101) and the engine room are located on the mothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com