Preparation process of biaxial orientation polyvinyl chloride (PVC)-U pipe

A PVC-U, polyvinyl chloride technology, applied in the direction of tubular items, household appliances, other household appliances, etc., can solve the problems of high resistance, traction slip, large temperature difference, etc., to reduce the temperature inside and outside, avoid traction slip, reduce The effect of traction tension friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

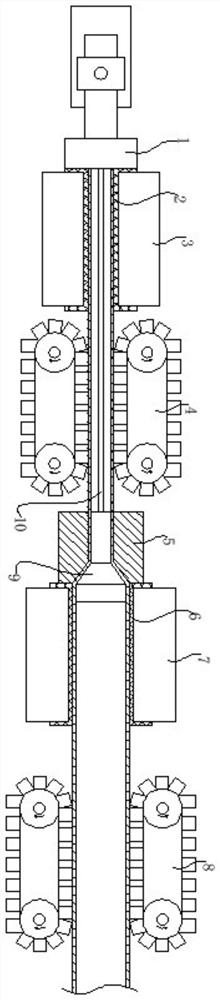

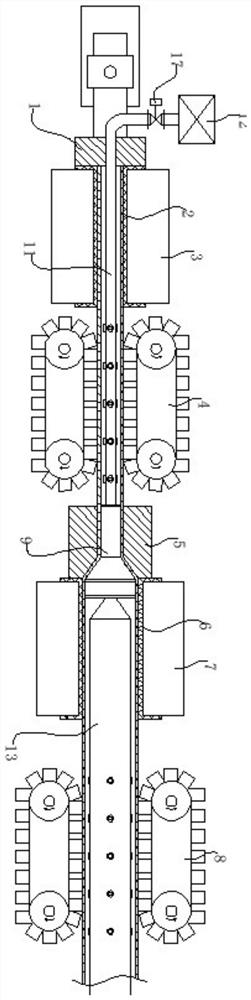

[0037] see Figure 2-5 As shown, the present invention is a preparation process of a biaxially oriented polyvinyl chloride PVC-U pipe, comprising the following steps:

[0038] Step 1: The plastic liquid with a temperature of 230-250°C is transported to the sizing sleeve 1 2 through the extruder 1, and the main engine speed of the extruder 1 is set at 230-240r / min;

[0039] Step 2: The cooling water tank 3 conducts heat conduction cooling on the sizing sleeve 1 2, and the cooling temperature is 16-20°C to obtain a cooled and shaped tube blank;

[0040] Step 3: The cooled and shaped tube blank is pulled and stretched by the tractor-4, and the speed of the tractor-4 is increased by 5%-6% compared with the extrusion speed of the extruder 1, so as to obtain the axially stretched tube blank ;

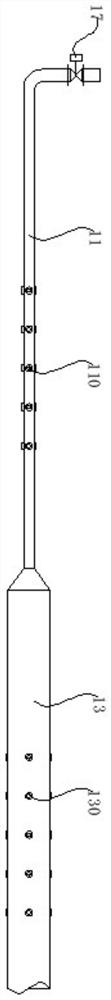

[0041] Step 4: While pulling and stretching the tube blank in Step 3, the cold air flow is input into the cooling air duct 1 11 through the cooling fan 12, and the cold air flows through th...

Embodiment 2

[0047] see Figure 4-5As shown, in step 5, the pedestal portion 90 and the truncated cone portion 91 are integrally formed, the truncated cone portion 91 and the extended pedestal portion 92 are detachably connected, and one side of the extended pedestal portion 92 is provided with a thread pattern of an integrated structure The stage 920, the thread pattern table 920 is threadedly connected in the thread pattern groove opened on the side end face of the frustum portion 91, and the flaring die 9 is composed of the pillar portion 90, the conical frustum portion 91 and the extension pillar portion 92, which is convenient for setting the heating fluid Cavity 900 and cooling fluid cavity 910, heating fluid cavity 900 and cooling fluid cavity 910 help reduce internal and external temperatures at the radially flared stretch location and help reduce traction stretch friction.

Embodiment 3

[0049] see Figure 4-5 As shown, a heating fluid chamber 900 is opened along the outline of the susceptor portion 90 and the frustum portion 91, and the open ends of the heating fluid chamber 900 are sealed and sealed by the end cap 14 and the silk thread platform 920 respectively, and the end cap 14 It is positioned and installed on the side end surface of the pedestal part 90 by bolts; a cooling fluid cavity 910 is opened along the outline of the extended pedestal part 92, and the open end of the cooling fluid cavity 910 is sealed and sealed by the end cover 2 15, and the end cover 2 15 is limited It is in contact with the rear end of the cooling air duct 1 11 , and the end cover 2 15 is easy to be positioned and installed on the side end surface of the extension column platform portion 92 by bolts, and the assembly and installation are convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com