Mechanical part grinding equipment based on intelligent manufacturing

A technology of mechanical parts and intelligent manufacturing, applied in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problem that the grinding head cannot adapt to various mechanical parts of different shapes, and replace the grinding head of different shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

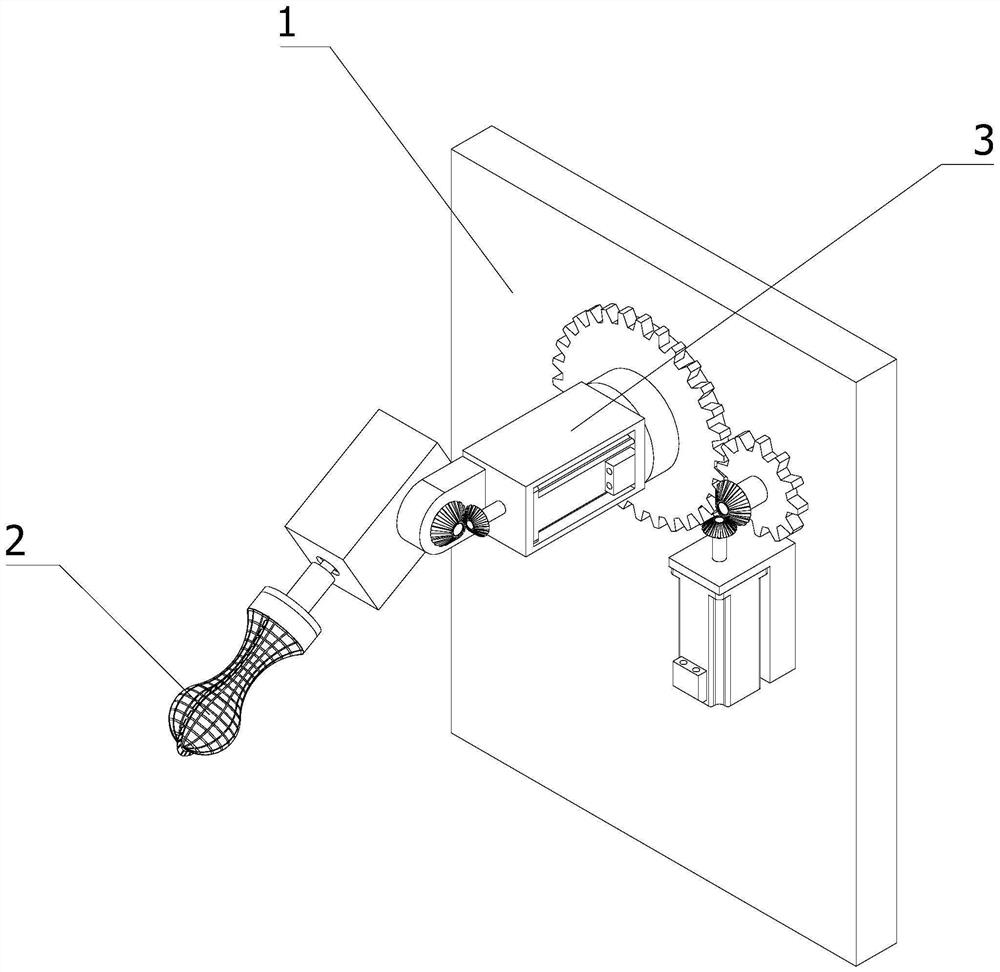

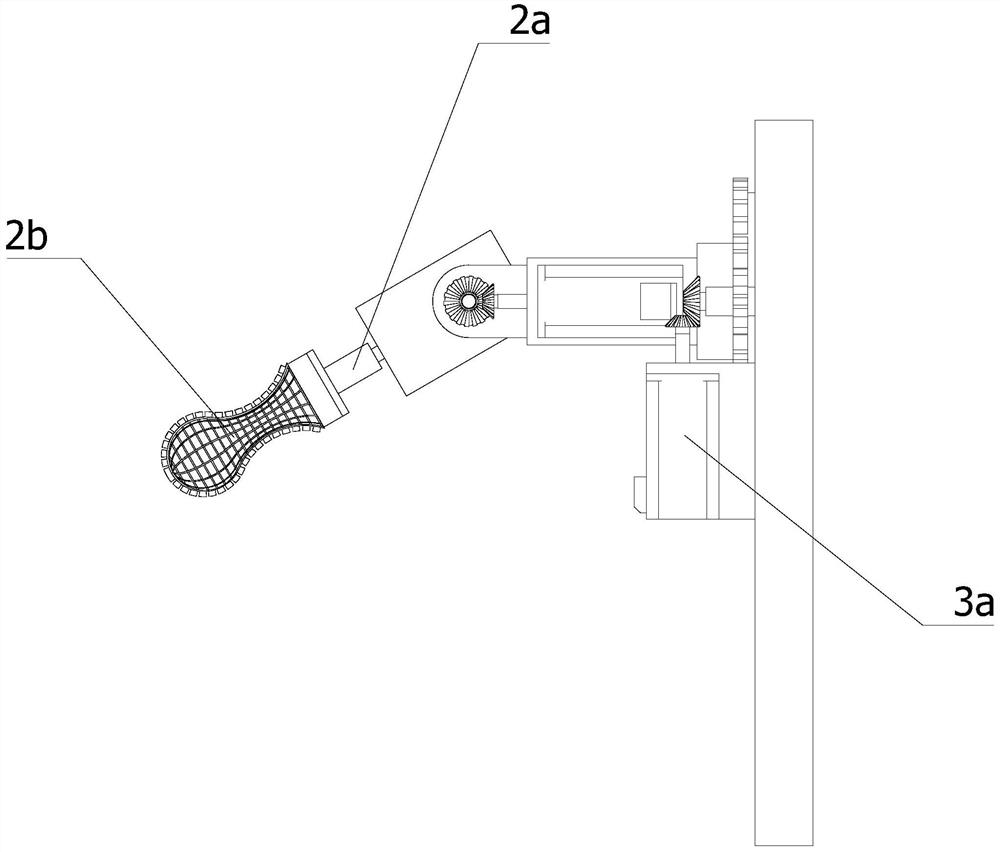

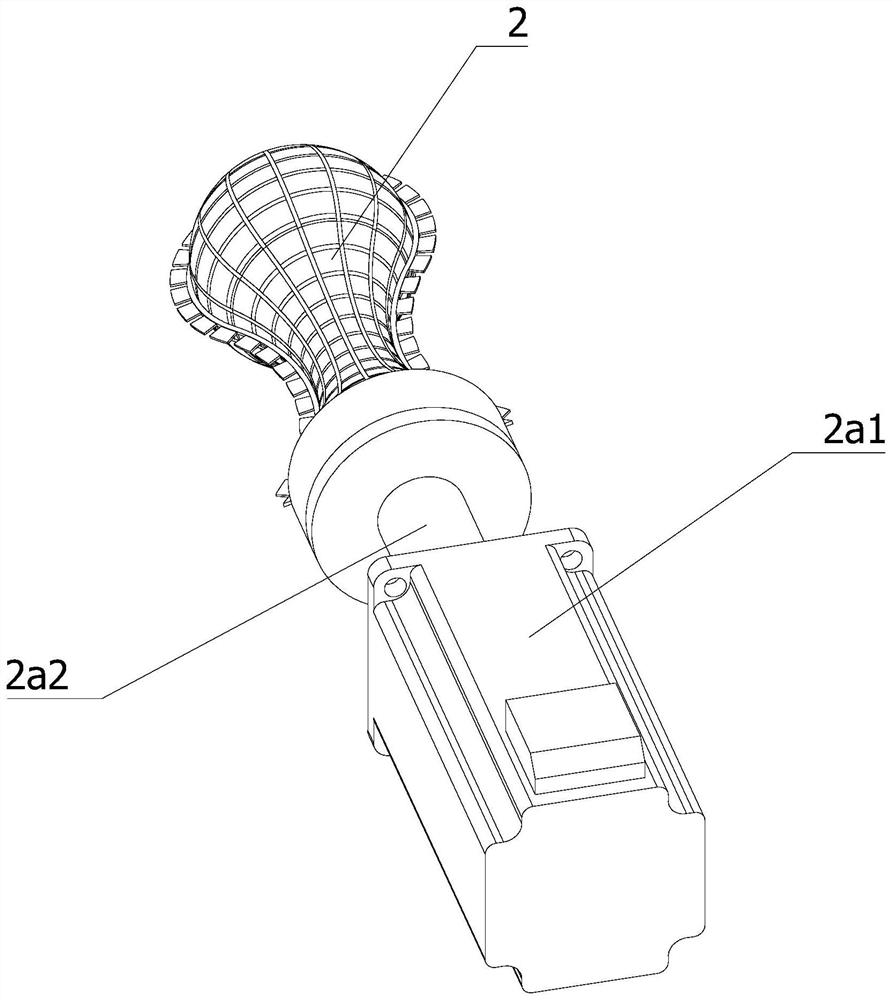

[0043] A mechanical parts grinding equipment based on intelligent manufacturing, comprising a frame 1, a grinding device 2 and a mechanical arm 3, the grinding device 2 is fixedly connected with the mechanical arm 3, and the grinding device 2 comprises a first rotary drive assembly 2a and a first grinding Assembly 2b, the first rotary drive assembly 2a is fixedly installed on the mechanical arm 3, the first grinding assembly 2b is fixedly installed on the grinding device 2, the first grinding assembly 2b includes a first flexible grinding head 2b1 and a supporting airbag 2b2, the first flexible Both the grinding head 2b1 and the supporting airbag 2b2 are made of flexible materials. The outer surface of the first flexible grinding head 2b1 is evenly distributed with grinding particles. The driving end is fixedly connected, the support airbag 2b2 is airtight, and the support airbag 2b2 is detachably installed in the first flexible grinding head 2b1; one end of the mechanical arm ...

no. 2 example

[0049] The sanding device 2 further includes a second sanding assembly 2c. The second sanding assembly 2c includes a second flexible sanding head 2c1, a first sealing cover 2c2, and a first air port 2c3. The second flexible sanding head 2c1 is made of a flexible material and has an outer surface. Grinding particles are evenly distributed, the second flexible grinding head 2c1 is airtight, the end of the second flexible grinding head 2c1 is fixedly connected to one end of the connecting shaft 2a2, and the first sealing cover 2c2 is rotatably mounted on the second flexible grinding head 2c1 , the first air inlet 2c3 is fixedly arranged on the first sealing cover 2c2.

[0050] Based on the above embodiment, the present application achieves the function of improving the adaptability of the second flexible grinding head 2c1 and changing the grinding force in real time through the second flexible grinding head 2c1, the first sealing cover 2c2 and the first air port 2c3, thereby solvi...

no. 3 example

[0052] The grinding device 2 further includes a third grinding component 2d, the third grinding component 2d includes a third flexible grinding head 2d1, a coarse sand surface 2d2, a fine sand surface 2d3, a second sealing cover 2d4 and a second air connection port 2d5, and the third flexible grinding head 2d1 The head 2d1 is made of a flexible material and has air tightness, the coarse sand surface 2d2 and the fine sand surface 2d3 are fixedly arranged on the third flexible sanding head 2d1 and are spaced apart, and the coarse sand surface 2d2 is fixedly arranged on the third flexible sanding head 2d1. The convex part can only be deformed slightly, the fine sand surface 2d3 is fixedly arranged in the depression of the third flexible grinding head 2d1 and can be greatly deformed, and the second sealing cover 2d4 is rotatably installed on the third flexible grinding head 2d1, The second air port 2d5 is fixedly arranged on the second sealing cover 2d4.

[0053] Based on the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com