Equipment health state assessment method

A technology of health status and equipment, applied in the direction of nuclear methods, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of difficult equipment failure assessment, achieve accurate assessment, and reduce the effect of part quality loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

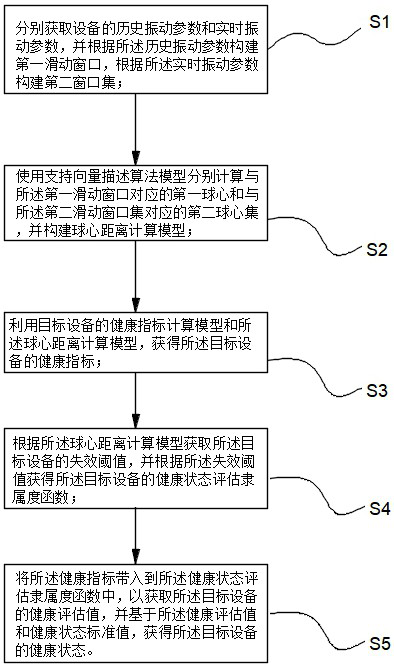

[0045] refer to figure 1 , the present application discloses a device health state assessment method, comprising the following steps:

[0046] S1, obtain the historical vibration parameter and the real-time vibration parameter of the target device respectively, and build the first sliding window according to the historical vibration parameter, and build the second sliding window set according to the real-time vibration parameter;

[0047] S11. Obtain historical data and real-time vibration parameters, and select characteristic values for evaluating the above parameters;

[0048] Extract the vibration parameters during the operation of the main shaft of the target equipment from the system database as historical vibration parameters; at the same time extract the vibration data during the operation of the target equipment as real-time vibration parameters, wherein the historical vibration parameters and real-time vibration parameters need to come from the same sensor pair The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com