Automatic drilling machine and method

A drilling machine, automatic technology, applied in the direction of drilling/drilling equipment, metal processing machinery parts, boring machine/drilling machine parts, etc., can solve the problem of automatic clamping, cumbersome operation steps, and reduce the efficiency of drilling machining and other issues to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

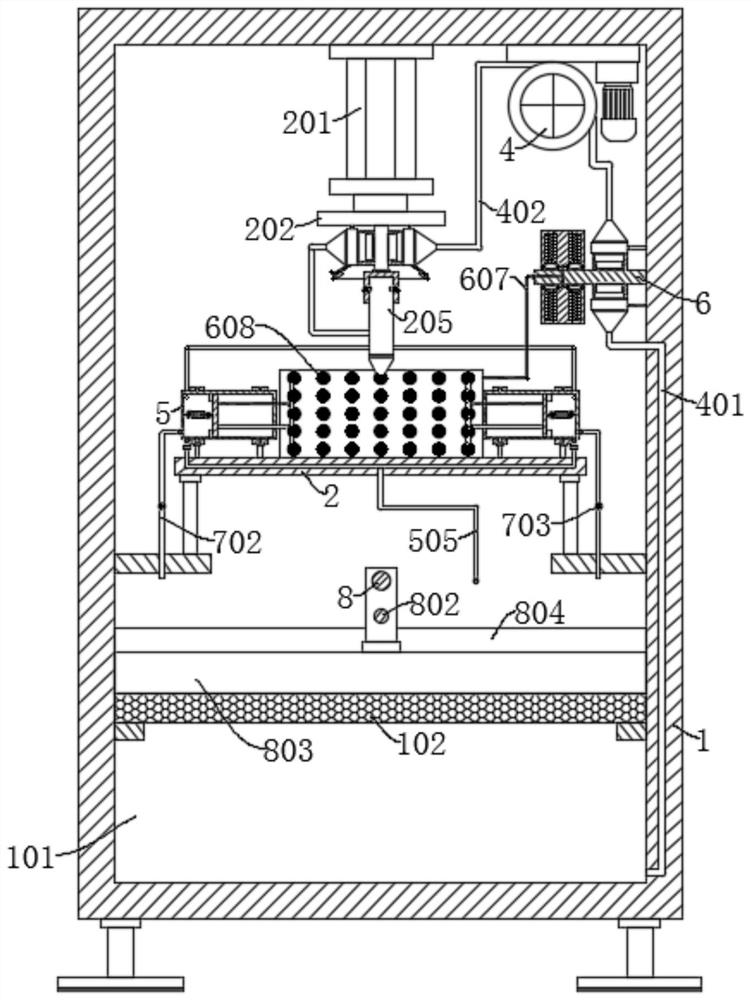

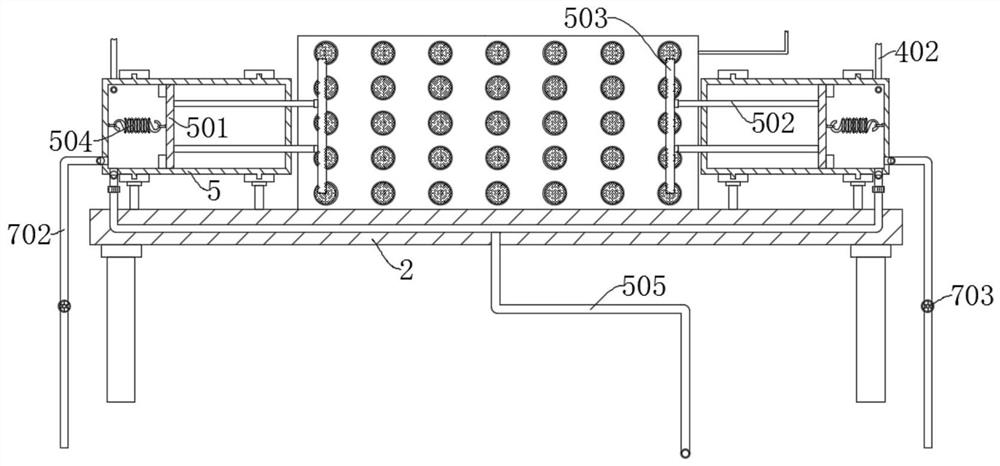

[0040] refer to Figure 1-Figure 9, an automatic drilling machine, comprising a box body 1, the inner wall of the box body 1 is fixedly connected with a workbench 2, and also includes: a water storage cavity 101 arranged in the box body 1, wherein the top inner wall of the box body 1 is provided with a The drilling mechanism for punching the workpiece; the water nozzle 805 is fixedly connected to the punching mechanism; the sleeves 5 are symmetrically arranged with two groups, the two groups of sleeves 5 are fixedly connected to the worktable 2, and the two groups of sleeves 5 A piston disc 1 501 is slidably connected inside; the connecting rod 502 is fixedly connected to the piston disc 1 501, and a clamping plate 503 is fixedly connected to the end of the connecting rod 502 away from the piston disc 1 501. The piston disc 1 501 and the sleeve 5 A tension spring 504 is connected between the inner walls of the bottom; a drain pipe 702 is connected to the sleeve 5, and a soleno...

Embodiment 2

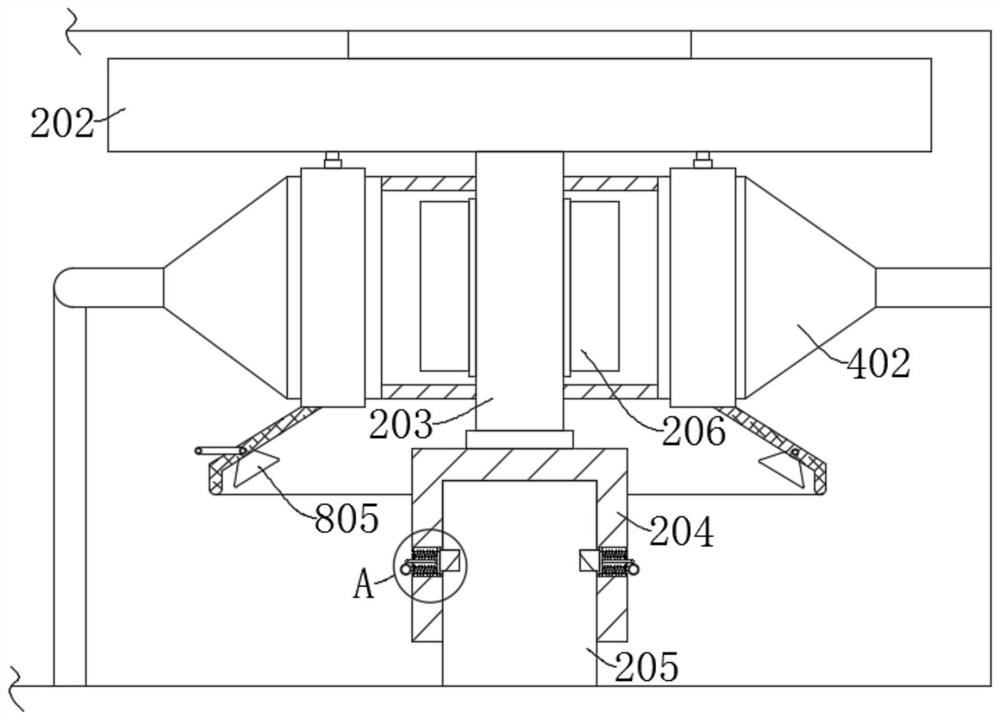

[0051] refer to figure 2 , Figure 7 , an automatic drilling machine, which is basically the same as Embodiment 1. Further, the outer wall of the drill bit 205 is provided with a clamping groove 3, the connecting sleeve 204 is provided with a groove 301, and a connecting block 302 is slidably connected in the groove 301. A spring one 303 is connected between the connection block 302 and the groove 301 , and the connection block 302 is inserted into the card groove 3 .

[0052] A pull rope 304 is fixedly connected to the connection block 302 , and a pull ring 305 is fixedly connected to one end of the pull rope 304 away from the connection block 302 .

[0053] When the drill bit 205 needs to be replaced, the operator pulls the pull ring 305, and the pull ring 305 drives the connecting block 302 to move through the pull rope 304, compressing the spring 1 303, so that the connecting block 302 is moved out from the slot 3 and retracted. In the groove 301, the operator can then ...

Embodiment 3

[0055] refer to figure 1 , Image 6 and Figure 9 , an automatic drilling machine, which is basically the same as Embodiment 1. Further, the inner wall of the box body 1 is provided with a guide assembly, the guide assembly is slidably connected with a scraper 803, and the inner wall of the box body 1 is rotatably connected with a reciprocating screw rod 8 The impeller 3 801 is fixedly installed on one end of the reciprocating screw rod 8 through the pressure relief pipe 505, the scraper 803 is threadedly connected with the reciprocating screw rod 8, the scraper 803 is attached to the surface of the activated carbon filter screen 102, and the box body 1 is provided with a row Feed port 804.

[0056] The guide assembly includes a guide rod 802 , the guide rod 802 is fixedly connected to the inner wall of the box body 1 , and the scraper 803 is slidably connected to the guide rod 802 .

[0057] When the water pressure in the sleeve 5 is greater than the safe value set by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com