Self-adaptive connecting mechanism for sliding block of bending machine and mounting method

A connection mechanism and self-adaptive technology, applied in the field of bending machine, to avoid bearing lateral force and good fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

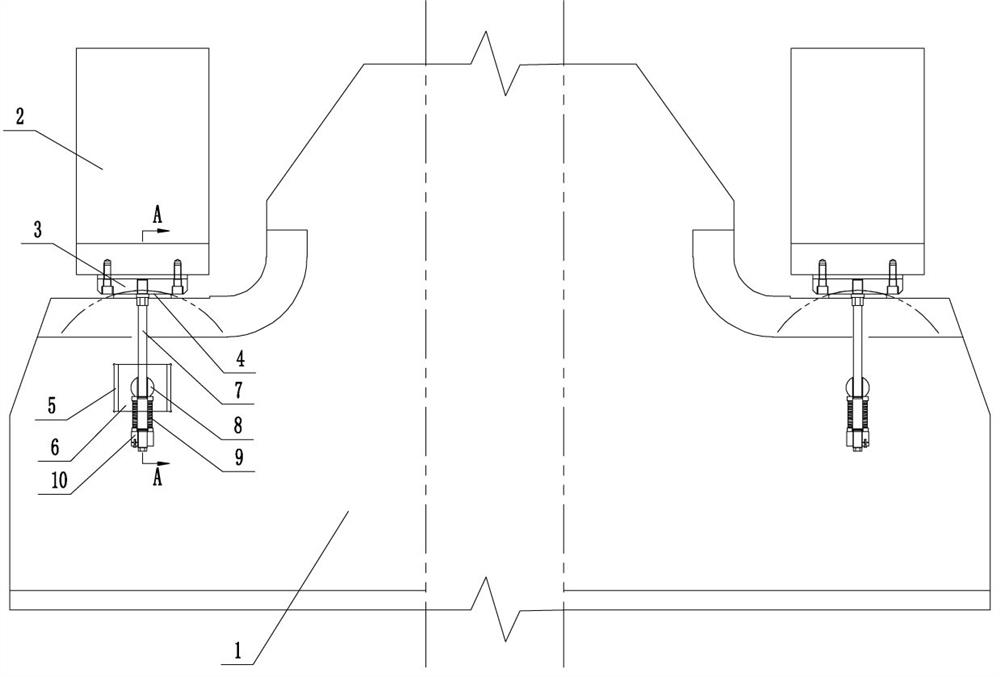

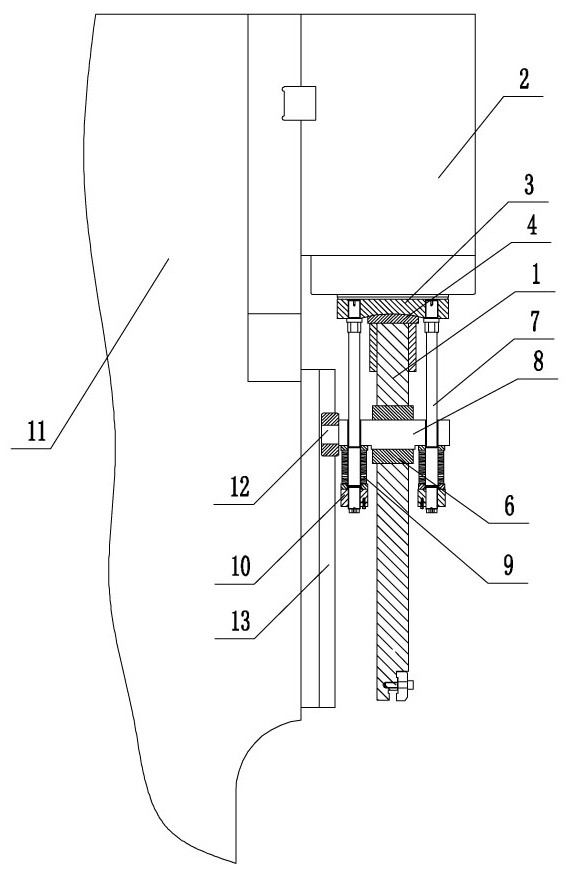

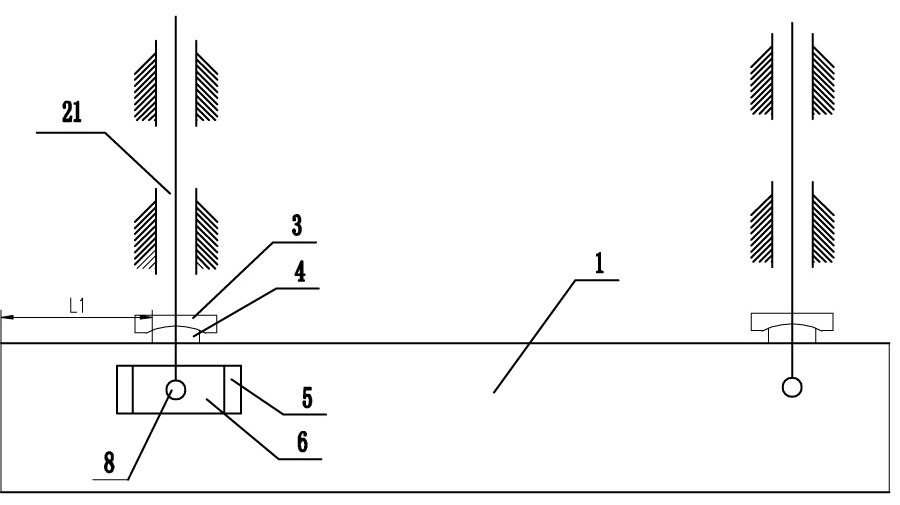

[0018] see Figure 1-2 , this embodiment is an adaptive connection mechanism of a bending machine slider, including a frame 11, a slider 1, an oil cylinder 2 is installed on both sides of the frame 11, and the bottom end of the piston rod 21 of each oil cylinder 2 is fixedly installed There is a concave ball pad 3, the top surface of the slider 1 is equipped with a convex ball pad 4 corresponding to the concave ball pad 3, the convex ball pad 4 cooperates with the concave ball pad 3, and the slider 1 is located directly below the two oil cylinders 2. A pin 8 is installed, each pin 8 runs through the slider 1, and a double-ended screw 7 is installed on both sides of the pin 8. The upper end of the double-ended screw 7 passes through the pin 8 and is connected with the corresponding concave ball pad. 3 is connected, the lower end of the double-ended screw 7 is equipped with a nut 10, the bottom surface of the convex ball washer 4 is slidably connected with the top surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com