Condensed and blocked pipeline dredging equipment

A pipe plugging and equipment technology, applied in the field of dredging equipment, can solve the problems of undesigned heating pipes, high risk, and inability to guarantee the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

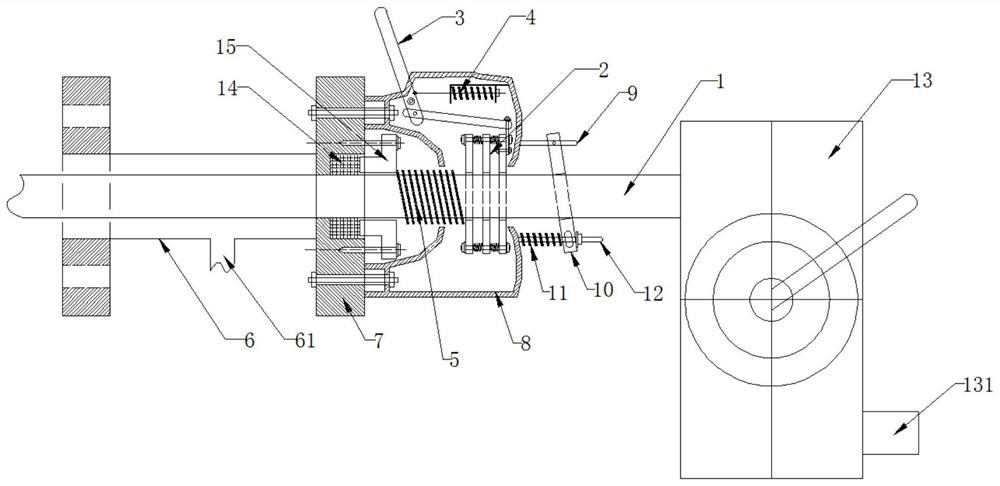

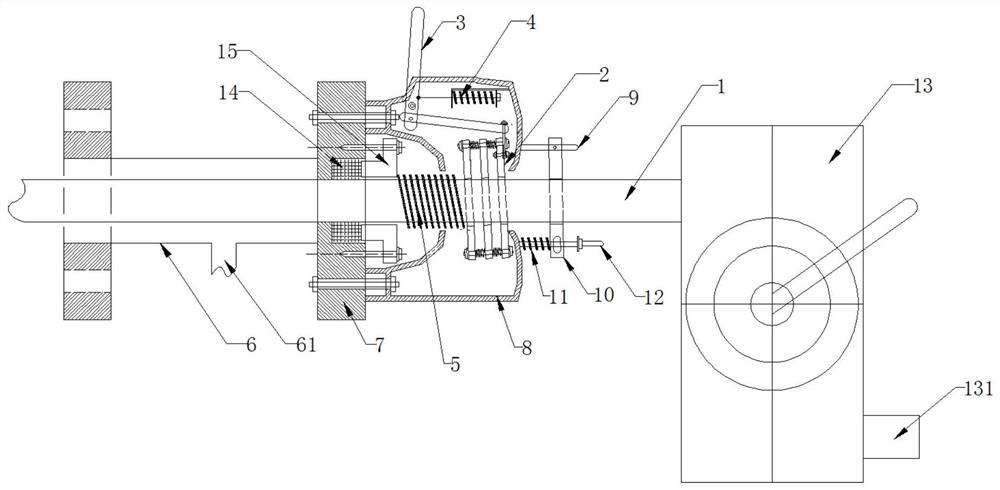

[0033] This embodiment provides a device for clearing a condensed and blocked pipeline, including a steam pipeline 1, a propulsion mechanism and a non-return mechanism. One end is used for introducing steam, the propulsion mechanism drives the steam pipeline 1 to move to the condensing pipeline synchronously or separates from the steam pipeline 1 and moves in the opposite direction to reset, and the non-return mechanism is used for the propulsion mechanism. The steam pipe is secured during reverse movement.

[0034] Wherein, the steam pipeline 1 can be a high-pressure and high-temperature-resistant rubber hose lined with steel mesh, or a high-pressure and high-temperature-resistant pipeline made of other materials. The steam pipeline 1 is preferably made of a material that can be bent, so that it can enter into the curved condensate pipeline. The diameter of the steam pipeline 1 needs to consider the diameter of the condensing pipeline, so as to ensure that the steam pipeline...

Embodiment 2

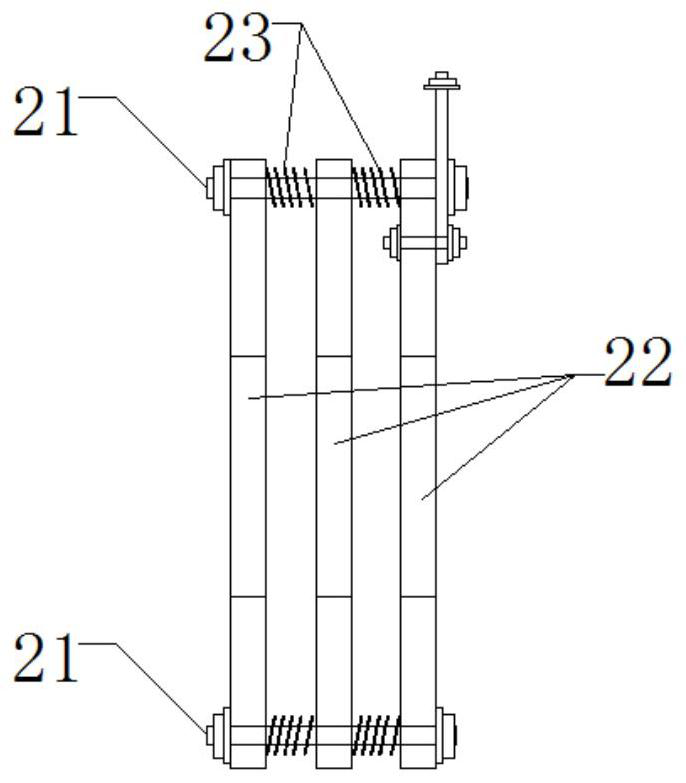

[0038] On the basis of Embodiment 1, for the propulsion mechanism, a manipulator can be used to grasp the steam pipeline 1 and move to the condensing pipeline, the manipulator can move in the opposite direction after releasing the steam pipeline 1, and the above-mentioned manipulator can automatically grasp or reset according to the control instruction. The loosening can be realized by using the prior art, and details are not repeated here; or the propulsion mechanism can also be: the propulsion mechanism includes a propulsion plate assembly 2, a propulsion handle 3 and a first elastic member 4, and the steam pipe 1 Pass through the pusher plate assembly 2 and move synchronously under the drive of the pusher plate assembly 2 when it moves to the blockage pipeline, and when the pusher plate assembly 2 moves in the opposite direction and resets with the pusher plate assembly 2 separation, one end of the push handle 3 is connected to the push plate assembly 2 and can drive the pus...

Embodiment 3

[0043] On the basis of Embodiment 2, the propulsion mechanism further includes a second elastic member 5, and the second elastic member 5 exerts a force on the propulsion plate assembly 2 to keep it away from the clogged pipeline.

[0044] After the pushing handle 3 is released, the second elastic member 5 assists the restoration of the pushing plate assembly 2 .

[0045] Wherein, the second elastic member 5 may be a coil spring, a butterfly spring or other elastic parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com