Drum-type hydraulic screen for sewage treatment

A sewage treatment and hydraulic sieve technology, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as leakage in the center roller area, affecting the filtering effect of hydraulic sieves, and difficult to remove silt, so as to reduce pressure and The effect of small weight and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

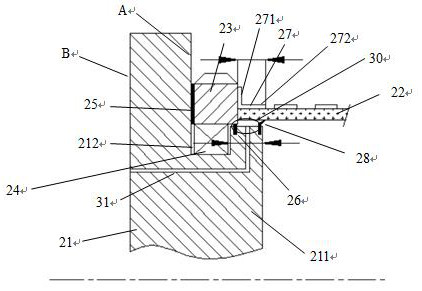

[0029] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

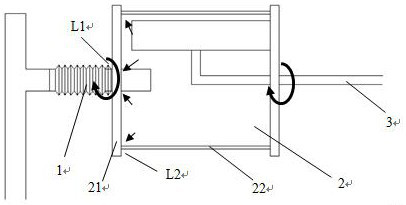

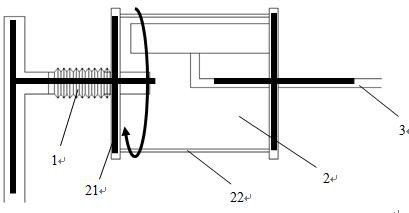

[0030] like figure 1 As shown, the drum hydraulic screen in the prior art has a water inlet pipe 1 , a drum 2 and a sewage outlet pipe 3 . The drum 2 with the screen mesh is rotatably connected to the water inlet pipe 1 and the water outlet pipe 3. Due to the long-term soaking of sewage and the high water pressure in the drum 2, sewage leakage often occurs at the rotating connection between the drum 2 and the water inlet and outlet pipes. Thereby, the sewage flows into the clean water tank; in addition, the drum 2 is composed of circular end plates 21 on both sides of the cylindrical screen 22 welded, and the annular welding seam will also have cracks, welding cracks, etc. Therefore, in the drum screen The connection part between 22 and the end plate 21 also belongs to the high leakage position. Although bearings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com