Method for degrading endosulfan by mechanochemical method

A mechanochemical method and endosulfan technology, which is applied in the field of environmental pollution waste treatment, can solve the problems of low degradation efficiency and slow degradation rate of endosulfan, and achieve simple process realization, low operating cost, and reduced energy consumption and operating cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Under normal temperature and pressure conditions, mix endosulfan pollutants with ball mill additives and place them in the ball mill tank of a planetary high-energy ball mill, add grinding balls into the ball mill tank and seal it, and then fix the loaded ball mill tank in the ball mill. On the above, the ball mill was carried out at a revolution speed of 275 rpm for 2 hours, and after every 30 minutes of continuous operation, it was stopped for 5 minutes to cool down, and the degradation of endosulfan was achieved by a mechanochemical reaction. Among them, the ball-milling additive is zero-valent metal Fe and quartz sand (5.5g, in which the molar ratio of zero-valent metal Fe and quartz sand is 4:1), the endosulfan pollutant is 0.5g, and the mass ratio of ball-milling additive and endosulfan pollutant is is 11:1, the total mass of the sample in the ball milling process is 6g, and the ball-to-material ratio is 30:1.

Embodiment 2

[0029]Under normal temperature and pressure conditions, mix endosulfan pollutants with ball mill additives and place them in the ball mill tank of a planetary high-energy ball mill, add grinding balls into the ball mill tank and seal it, and then fix the loaded ball mill tank in the ball mill. On the above, the ball mill was carried out at a revolution speed of 275 rpm for 2 hours, and after every 30 minutes of continuous operation, it was stopped for 5 minutes to cool down, and the degradation of endosulfan was achieved by a mechanochemical reaction. Among them, the ball-milling additive is calcium oxide (CaO) 5.5g, the endosulfan pollutant is 0.5g, the mass ratio of the ball-milling additive and the endosulfan pollutant is 11:1, the total mass of the sample during the ball-milling process is 6g, and the ball-to-material ratio is 30:1.

Embodiment 3

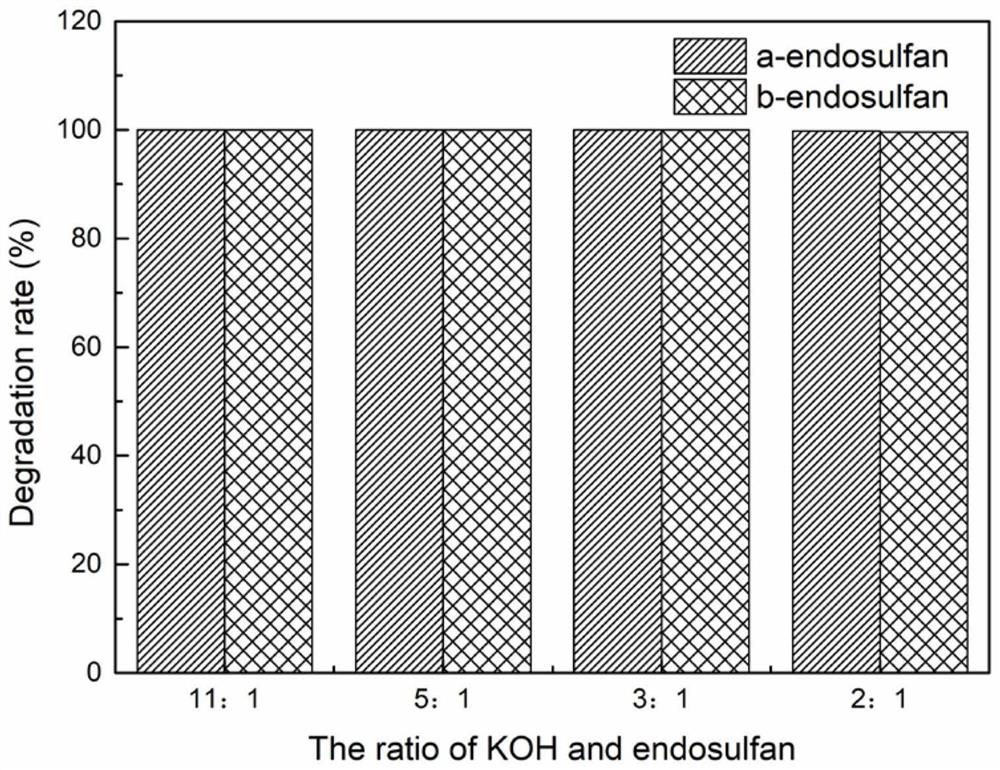

[0031] Under normal temperature and pressure conditions, mix endosulfan pollutants with ball mill additives and place them in the ball mill tank of a planetary high-energy ball mill, add grinding balls into the ball mill tank and seal it, and then fix the loaded ball mill tank in the ball mill. On the above, the ball mill was carried out at a revolution speed of 275 rpm for 2 hours, and after every 30 minutes of continuous operation, it was stopped for 5 minutes to cool down, and the degradation of endosulfan was achieved by a mechanochemical reaction. Among them, the ball-milling additive is potassium hydroxide (KOH) 5.5g, the endosulfan pollutant is 0.5g, the mass ratio of the ball-milling additive and the endosulfan pollutant is 11:1, the total mass of the sample during the ball-milling process is 6g, and the ball-to-material ratio 30:1.

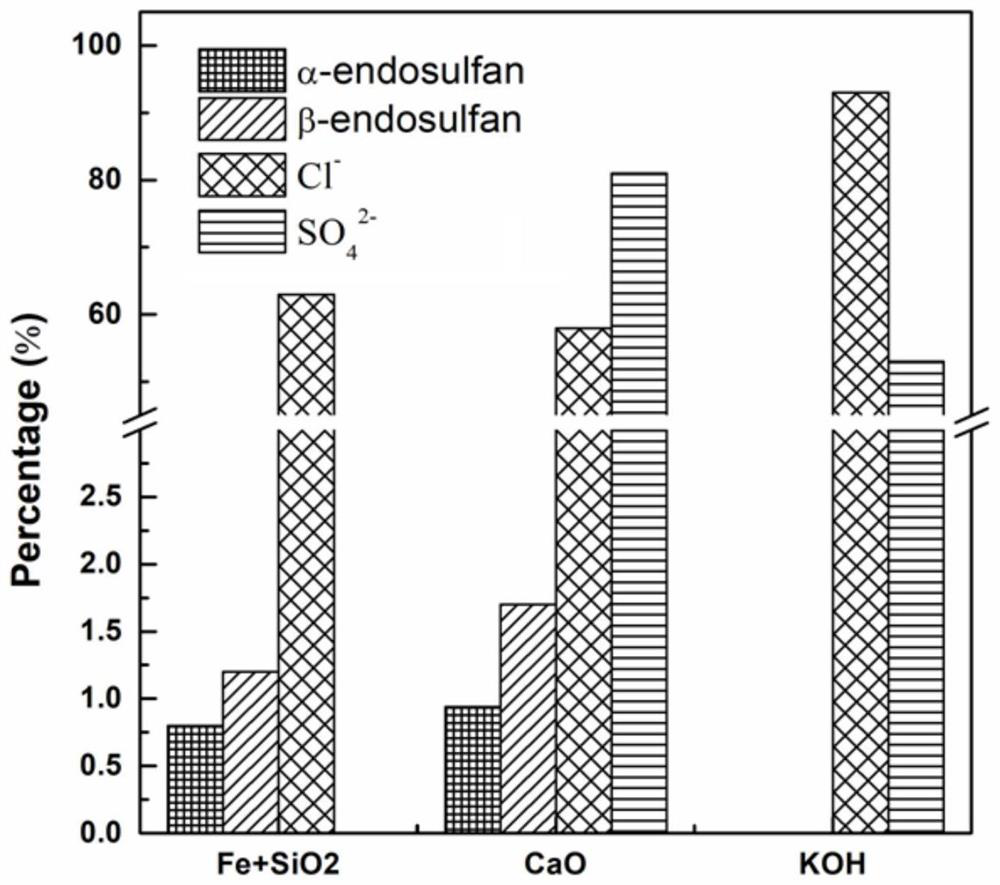

[0032] Examples 1-3 use different ball mill additives to degrade endosulfan, and the results are as follows figure 1 shown. from figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com