Double temperature double bed gasification, oxidization and fluidized bed incinerator for disposing high concentration organic effluent liquor

A high-temperature oxidation technology for organic waste liquid, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of low dechlorination efficiency of absorbents, coking of bed materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

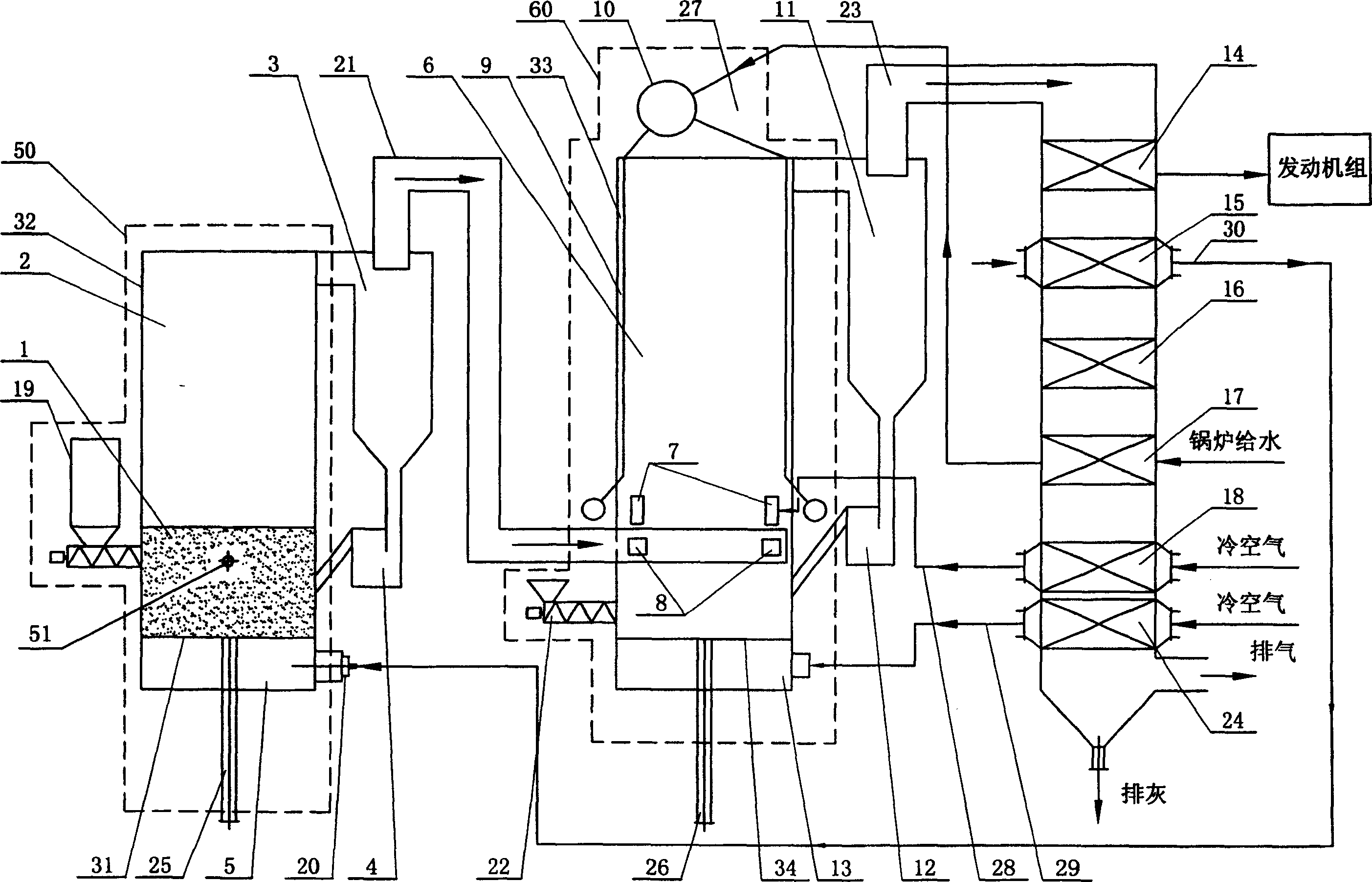

[0005] Specific implementation mode one: (see figure 1 ) This embodiment consists of a low-temperature gasification fluidized bed 50, a high-temperature oxidation circulating fluidized bed 60, a cyclone separator 3, a first feeding device 4, a low-temperature flue 21, a high-temperature cyclone separator 11, and a second feeding device 12 , high temperature exhaust flue 23, high temperature air preheater 15, economizer 17, first low temperature air preheater 18, second low temperature air preheater 24, secondary air pipeline 28, primary air pipeline 29, high temperature The air pipeline 30 is composed of; one side of the upper part of the cyclone separator 3 is fixedly connected with the upper part of the low-temperature gasification fluidized bed 50, and the lower end of the cyclone separator 3 is fixedly connected with one side of the first feeding device 4, and the first feeding device The other side of 4 is fixedly connected with the lower part of the low-temperature gasif...

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 1 ) The difference between this embodiment and the first embodiment is that a high-temperature superheater 14 is added to the high-temperature exhaust flue 23 between the high-temperature cyclone separator 11 and the high-temperature air preheater 15 . A low-temperature superheater 16 is added to the high-temperature exhaust flue 23 between the high-temperature air preheater 15 and the economizer 17 . Other compositions and connections are the same as in the first embodiment.

[0007]The invention can treat 200-1000 t / d of organic waste liquid per day. After the cold air is preheated to 500-550°C by the high-temperature air preheater 15, it is sent into the fluidized bed air chamber 5, and an auxiliary burner 20 is arranged at the entrance of the fluidized bed air chamber 5. It starts when the temperature inside 1 is lower than 500°C, and stops automatically when it is higher than 600°C, so as to ensure that the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com