Nuclear power plant pump equipment

A technology of power plants and nuclear energy, applied in the field of pump equipment, can solve problems such as laborious work and radiation exposure of operators, and achieve the effects of reducing radiation exposure, reducing radiation exposure, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

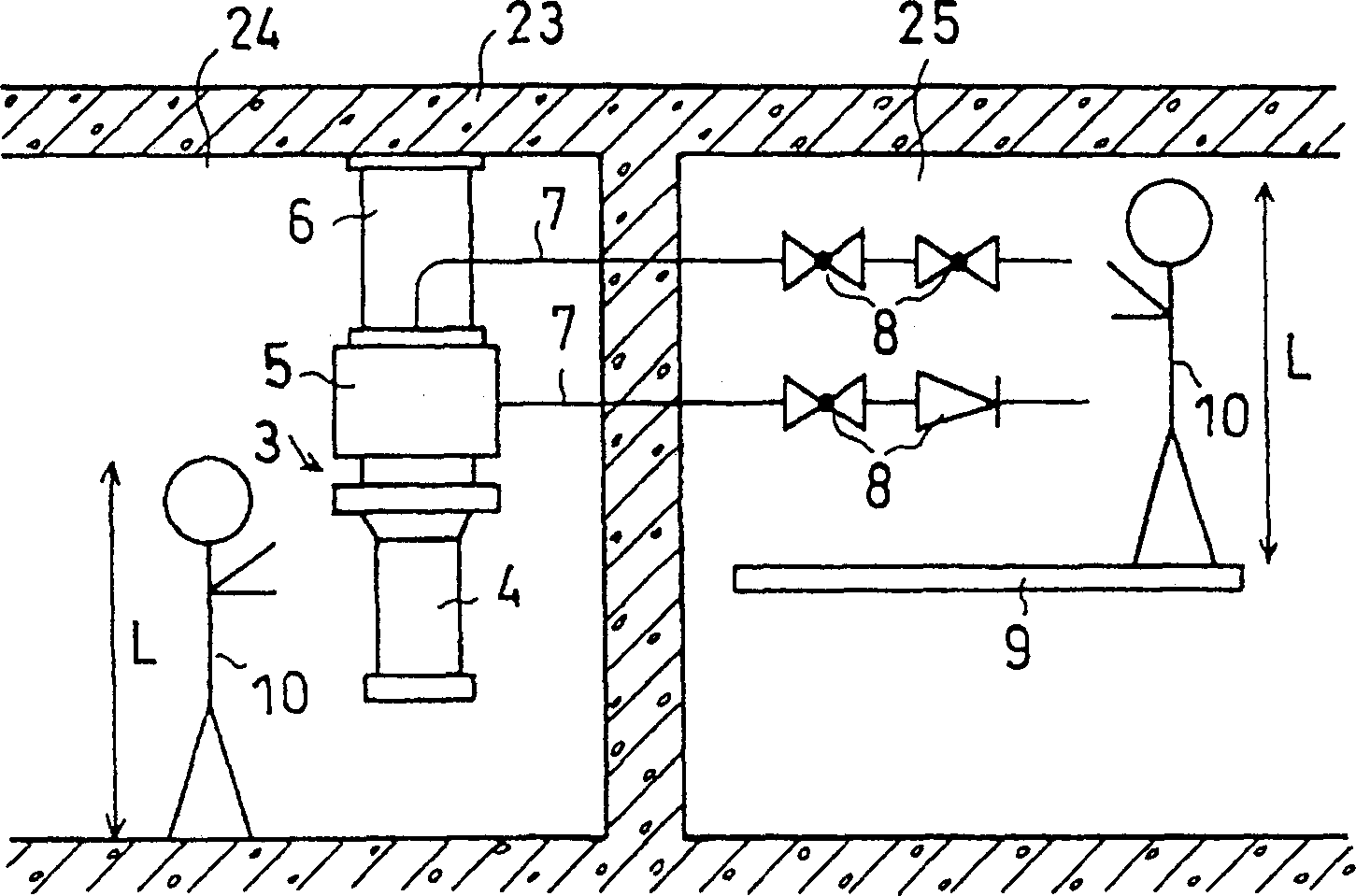

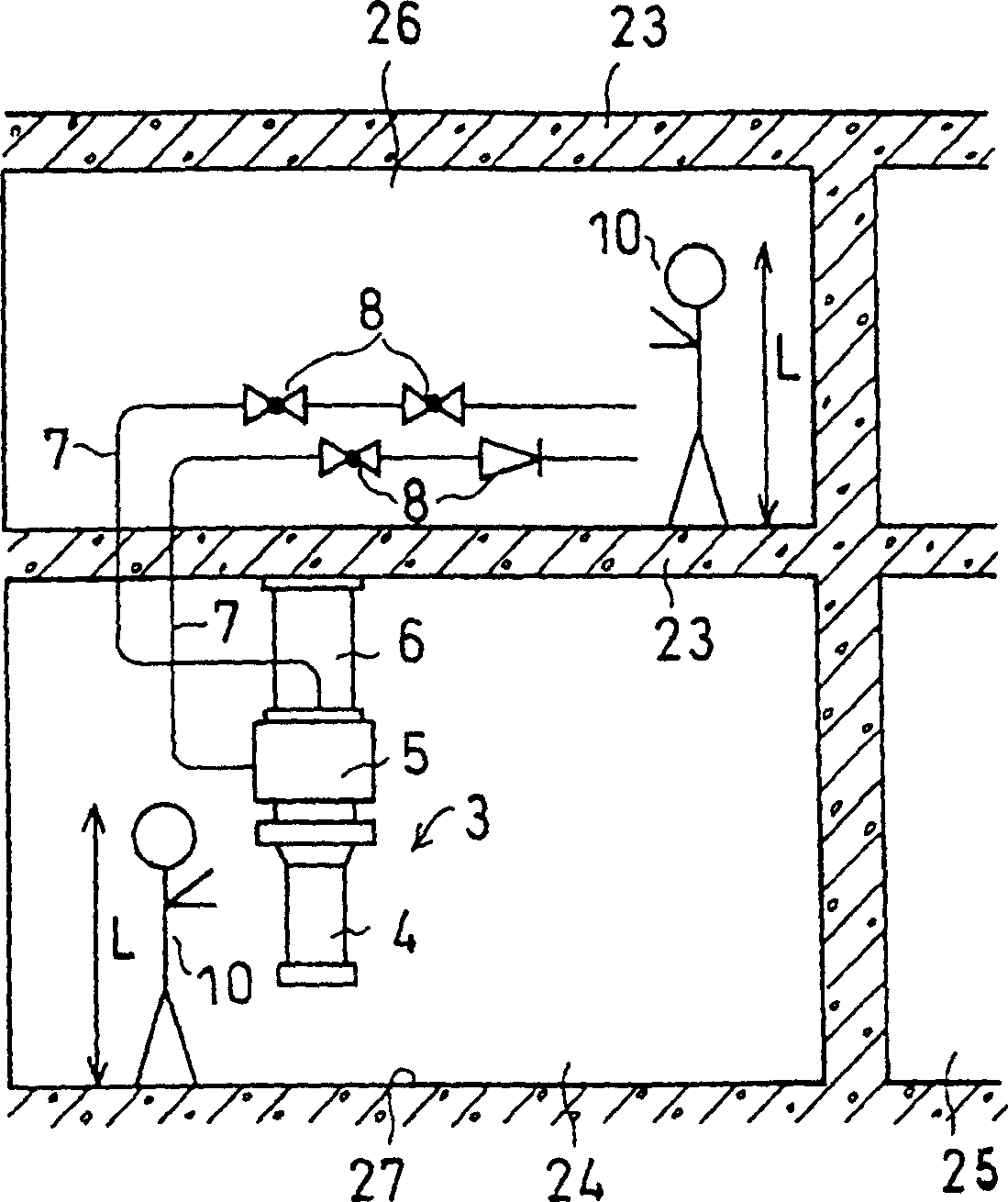

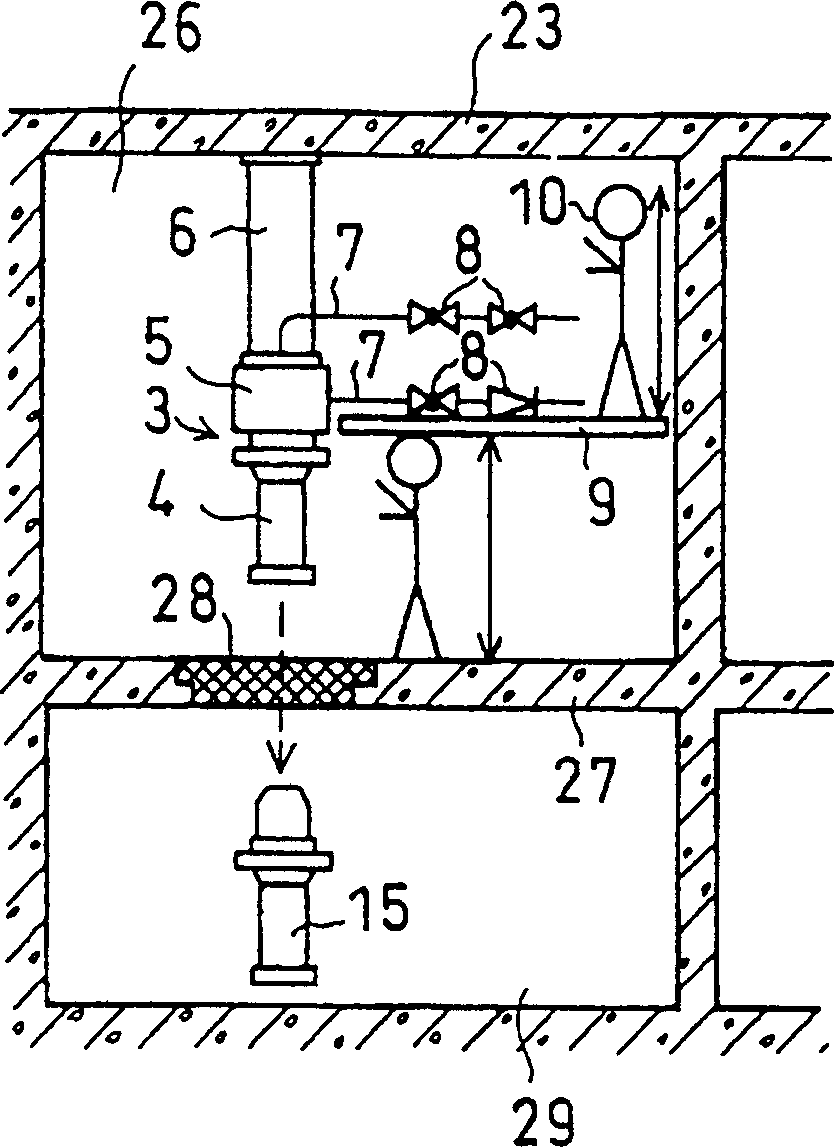

[0049] Refer below figure 1 A first embodiment of the vertical shaft pump equipment of the present invention will be described.

[0050] exist figure 1 neutralize Figure 16 The same parts are given the same reference numerals. Repeated parts are omitted. In this embodiment, a machine room 24 with a floor height lower than that of the conventional example is provided in the building body 23. In this machine room 24, the vertical shaft pump 3 is suspended from the ceiling. A pipe 7 and a suction valve and a discharge valve (hereinafter referred to as a valve) 8 are arranged in the provided adjacent chamber 25 .

[0051] That is, in figure 1 Among them, the piping 7 and the valve 8 attached to the vertical shaft pump 3 are arranged in the adjacent chamber 25 adjacent to the machine room 24 where the vertical shaft pump 3 is installed, and the vertical shaft pump 3 and the valve 8 are arranged in parallel. In the pump area like this, because there is no valve, just needn'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com