Organic photoelectric device based on metal-induced organic interface layer and preparation method

A photoelectric device, metal-induced technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as poor stability of formally mounted devices, achieve good stability, excellent comprehensive performance, and simple and easy-to-operate manufacturing methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

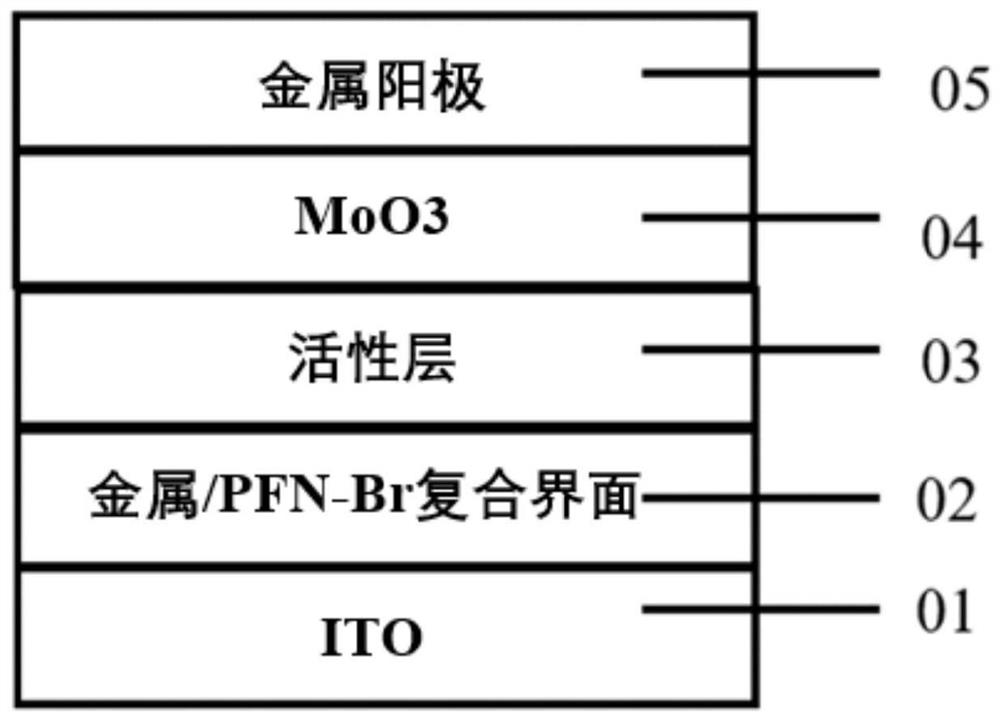

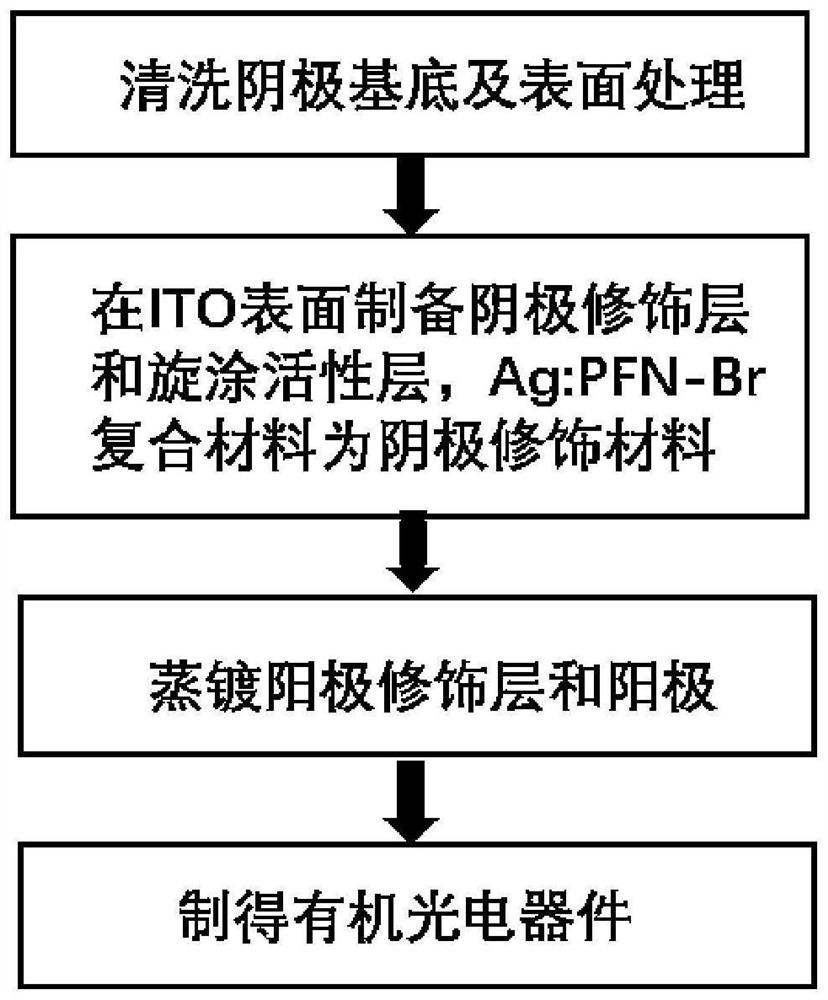

[0038] In this example, the Ag / PFN-Br composite interface is applied to the preparation of organic optoelectronic devices, and the organic optoelectronic devices are organic solar cells. The specific preparation steps are as follows:

[0039] (1) First clean the ITO glass to ensure that its surface is free of any contaminants. Put the ITO glass into deionized water, add 15mL of detergent, and then ultrasonicate for 20 minutes, repeat 2-3 times, and then wash with deionized water 2-3 times; then ultrasonically clean the ITO glass with isopropanol twice, each time 20 minutes; finally, put the ITO glass in an oven at 70°C for 12 hours and use it for later use.

[0040] (2) Move the treated ITO glass into the evaporation system, at 4 × 10 -4 Ag was evaporated to 1 nm under the pressure of Pa and placed in a nitrogen glove box. The pre-prepared PFN-Br solution (the weighed PFN-Br powder was added to methanol to dissolve, heated and stirred at 55 °C for 4 hours, the solution conc...

Embodiment 2

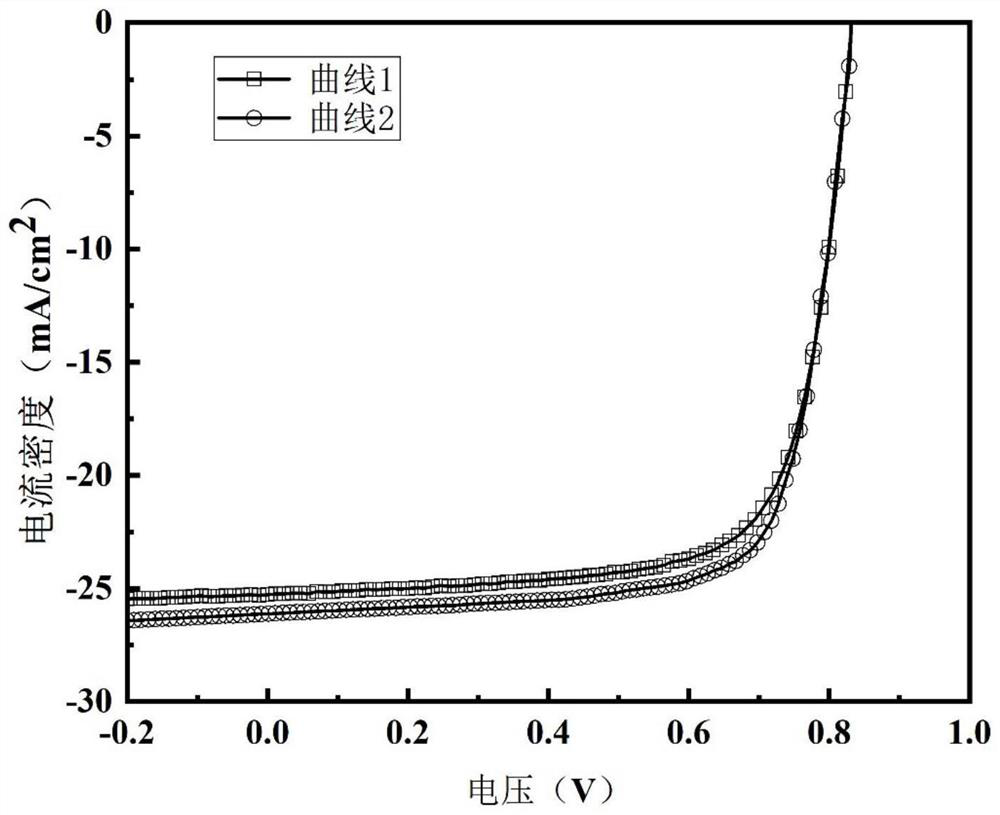

[0055] In this example, the Ag / PFN-Br composite interface is still applied to the preparation of flip-chip organic optoelectronic devices, the organic optoelectronic devices are organic solar cells, and the device structure is ITO / Ag / PFN-Br / PTB7-Th:PCBM / MoO 3 / Ag. The specific preparation steps are as follows:

[0056] (1) First clean the ITO glass to ensure that its surface is free of any contaminants. Put the ITO glass into deionized water, add 15mL of detergent, and then ultrasonicate for 20 minutes, repeat 2-3 times, and then wash with deionized water 2-3 times; then ultrasonically clean the ITO glass with isopropanol twice, each time 20 minutes; finally, put the ITO glass in an oven at 70°C for 12 hours and use it for later use.

[0057] (2) Move the treated ITO glass into the evaporation system, at 4 × 10 -4 Ag was evaporated to 1 nm under the pressure of Pa and placed in a nitrogen glove box. The pre-prepared PFN-Br solution (the weighed PFN-Br powder was added to...

Embodiment 3

[0066] This example applies the Ag / PFN-Br composite interface to the preparation of high-performance organic photodetectors. The preparation process is basically the same as the preparation method of the previous organic optoelectronic device (organic solar cell). The device structure is ITO / Ag / PFN-Br / PTB7-Th:COTIC-4F / MoO 3 / Al.

[0067] (1) First clean the ITO glass to ensure that its surface is free of any contaminants. Put the ITO glass into deionized water, add 15mL of detergent, and then ultrasonicate for 20 minutes, repeat 2-3 times, and then wash with deionized water 2-3 times; then ultrasonically clean the ITO glass with isopropanol twice, each time 20 minutes; finally, put the ITO glass in an oven at 70°C for 12 hours and use it for later use.

[0068] (2) Move the treated ITO glass into the evaporation system, at 4 × 10 -4 Ag was evaporated to 1 nm under the pressure of Pa and placed in a nitrogen glove box. The pre-prepared PFN-Br solution (the weighed PFN-Br p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com