Single-leaning-tower cable-stayed bridge construction control method

A control method and cable-stayed technology, which is applied in the field of construction control of a cable-stayed bridge with a single leaning tower, can solve the problems of difficult construction of the leaning tower, difficulty in controlling the stress and linearity of the leaning tower, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

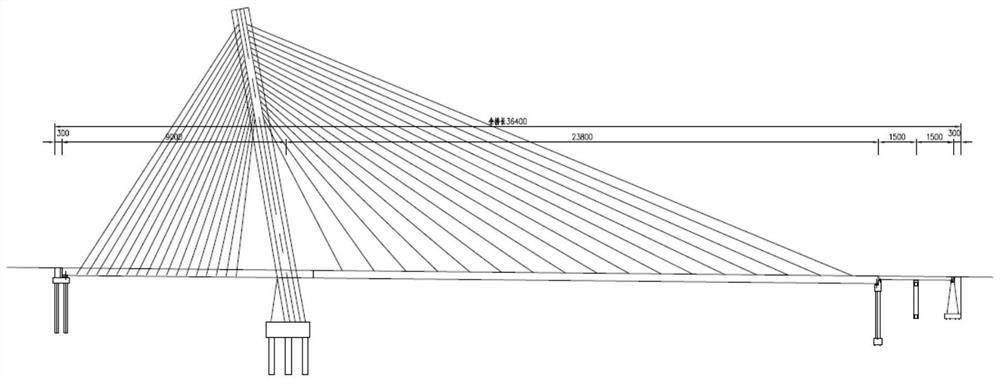

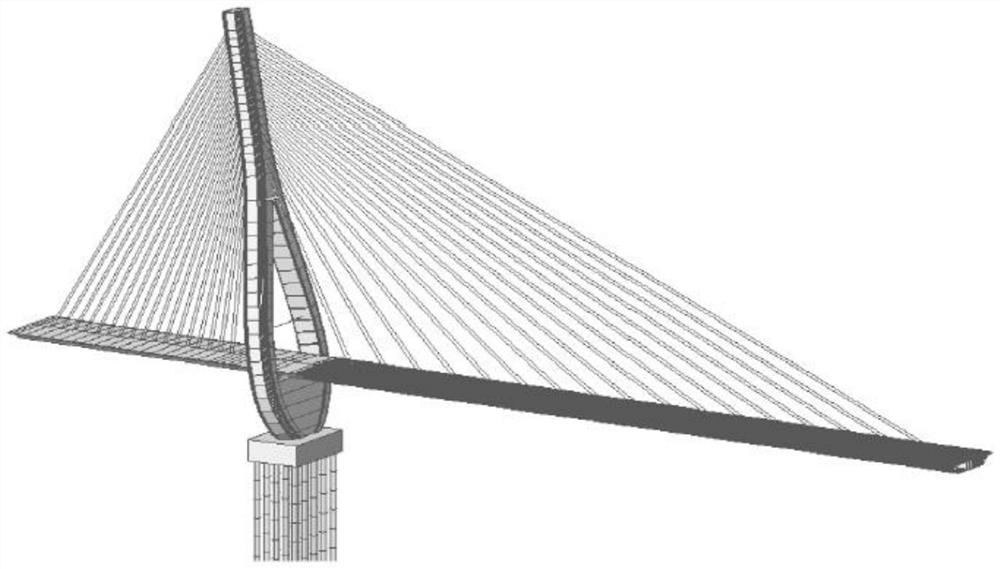

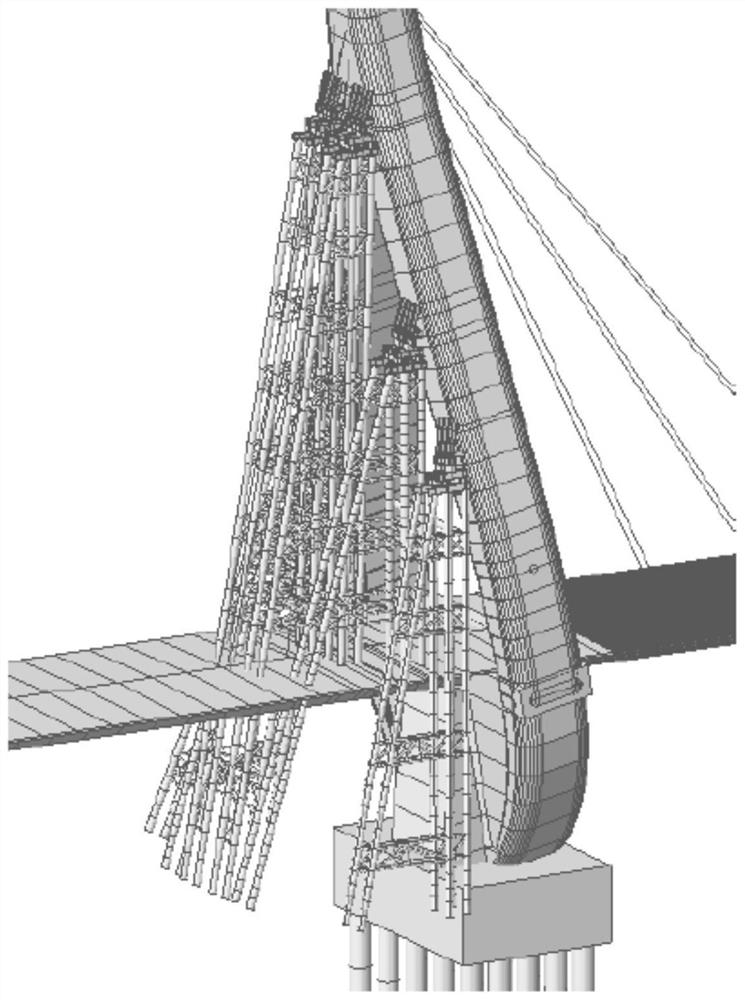

[0033] The construction control method of a single leaning tower of the present invention adopts multiple control means of supporting active jacking force, cable tension and main girder counterweight. The method is further described in detail with reference to the accompanying drawings, and is specifically applied to a cable-stayed bridge with a single tower leaning tower. Construction example, including the following steps:

[0034] Step 1. Establish the finite element model of the whole bridge: According to the information of the single-tower cable-stayed bridge to be constructed, the Midas / Civil finite element analysis software is used to establish a refined construction process model of the whole bridge. The main beam, main pier and bridge tower are simulated by space beam element, and the stay cable is simulated by tension-only truss element. The back support of the bridge tower is made of steel pipe material, the upper fulcrum of the back support and the bridge tower are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com