Method for detecting aspartame in wine

A detection method, the technology of aspartame, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as separation difficulties, and achieve the effect of rapid analysis method, high sensitivity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

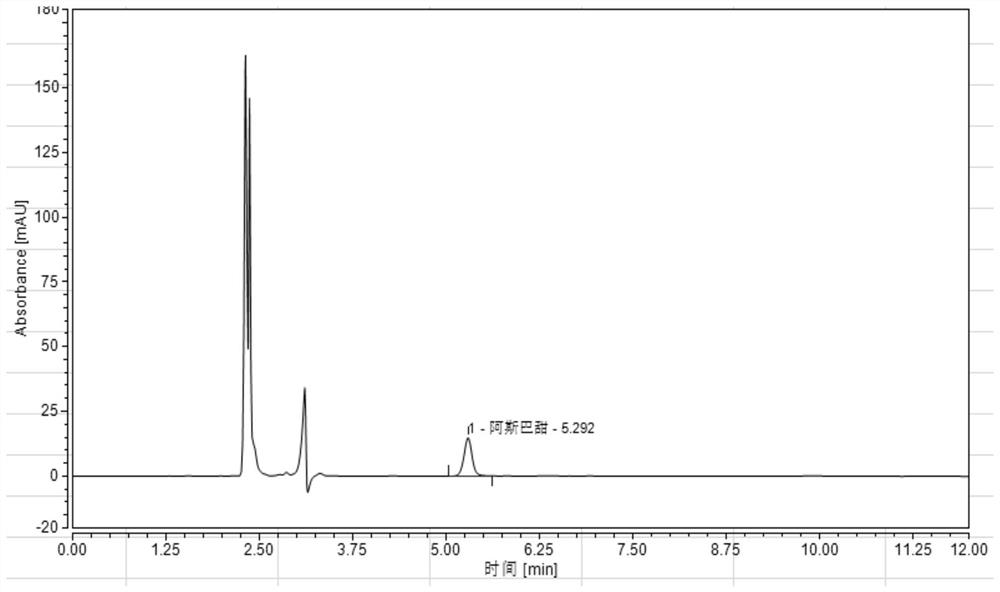

Embodiment 1

[0032] Accurately weigh about 5g of white wine in a beaker, and ultrasonicate in a water bath at 60°C for 10min without alcohol odor. Transfer the sample liquid to a 25mL volumetric flask, continue to add 5mL of distilled water to the beaker and then sonicate for 5min, transfer the liquid to the same volumetric flask, repeat the above operation, and dilute to the mark with water. The constant volume liquid was analyzed according to the instrument conditions of high performance liquid chromatography.

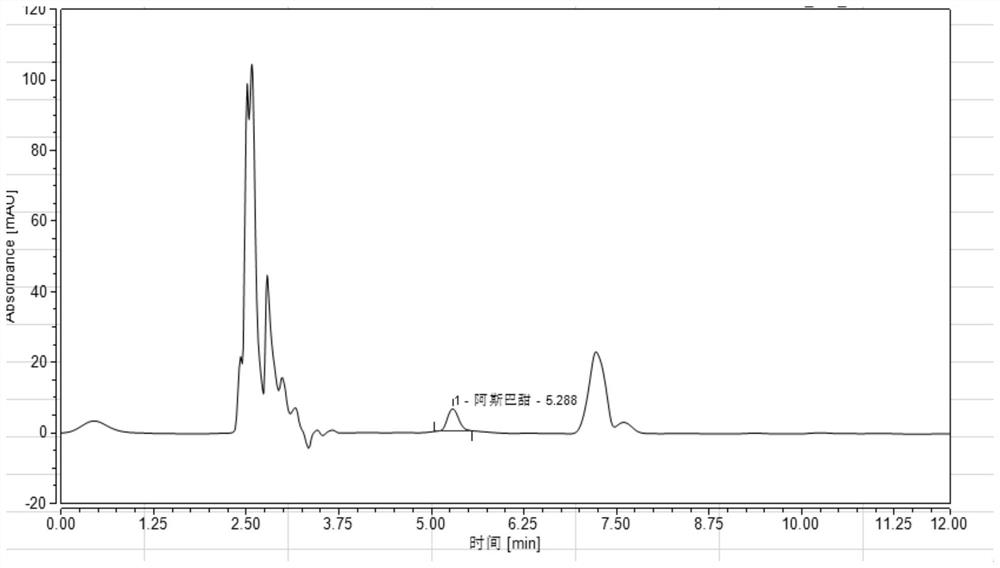

Embodiment 2

[0034] Accurately weigh about 5g of kiwifruit wine into a beaker. After ultrasonication in a water bath at 60°C for 10min without alcohol odor, add 10mL of 50% methanol water and 1g of graphitized carbon and shake well. After continuing to ultrasonicate for 10min, transfer the sample solution to a 25mL volumetric flask. Continue to add 5 mL of 50% methanol water to the beaker, then sonicate for 5 min, transfer the liquid to the same volumetric flask, repeat the above operation, and dilute to the mark with water. After vortexing and mixing, it was poured into a centrifuge tube, centrifuged at 3000 r / min for 3 min, and the supernatant was taken for analysis according to the instrument conditions of high performance liquid chromatography.

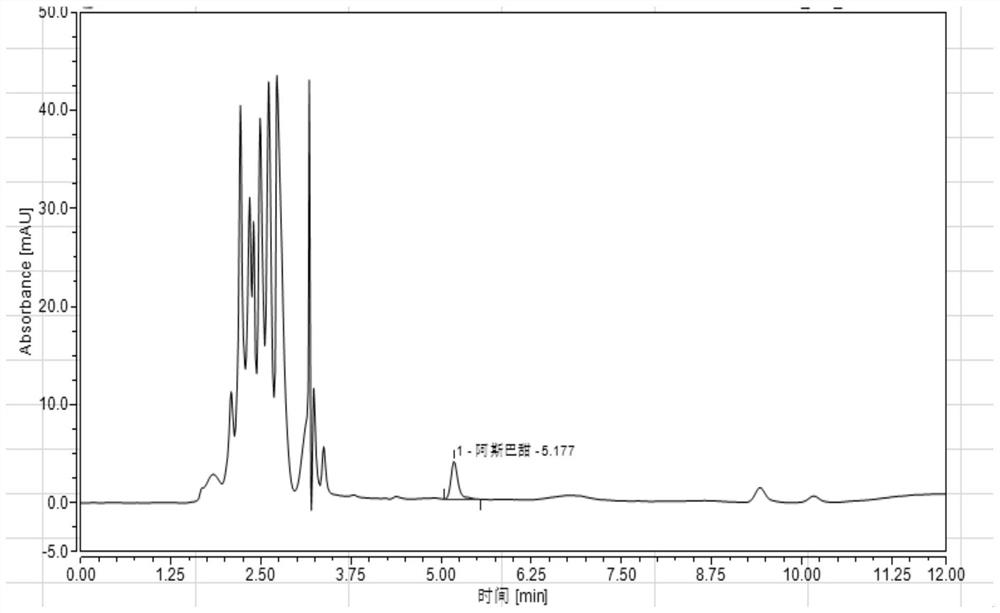

Embodiment 3

[0036] Accurately weigh about 5g of mashed grains (or rice wine) in a beaker. After ultrasonication in a 60°C water bath for 10min without alcohol odor, transfer the sample solution to a 50mL volumetric flask. Continue to add 5mL of distilled water to the beaker and ultrasonicate for 5min. Transfer the liquid to a 50mL volumetric flask. In the same volumetric flask, repeat the above operation. Add 1.0 mL of potassium ferrocyanide solution and 1.0 mL of zinc acetate solution to the volumetric flask, dilute to the mark with water, vortex and mix, pour into a centrifuge tube, and centrifuge at 3000 r / min for 3 min. The supernatant was taken for analysis according to the instrumental conditions of high performance liquid chromatography.

[0037] The above three samples were analyzed by standard addition and recovery quality control methods. The content (μg / g) of aspartame in the samples measured by the same laboratory and its precision are shown in Table 1.

[0038] Precision: T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com