Ventilation equipment for electric wire plastic sheath production workshop

A technology for production workshops and ventilation equipment, applied in space heating and ventilation, space heating and ventilation details, ventilation systems, etc., can solve the problem of poor filtration and collection of large particles of dust, imperfect purification of harmful gases, and simple filtration and other issues to achieve the effect of improving mobility and practicality, maintaining functionality, and ensuring freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

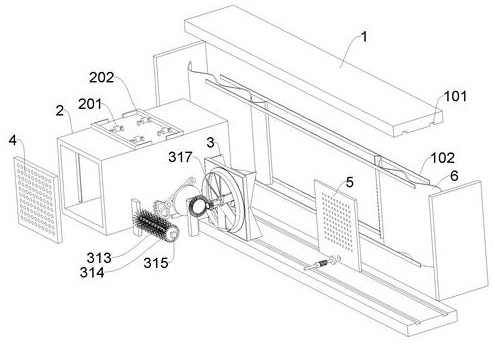

[0043] refer to Figure 1-Figure 7 , a kind of ventilation equipment for the production workshop of electric wire plastic sheath, including,

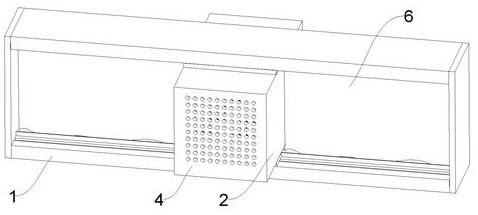

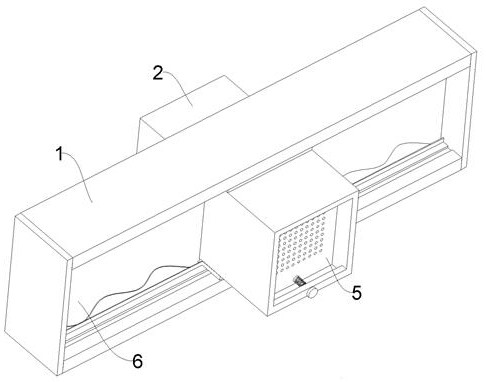

[0044] The fixed frame 1, the upper and lower inner walls of the fixed frame 1 are cut with two chutes 101;

[0045] Ventilation pipe 2, the ventilation pipe 2 is slidably connected to the interior of the fixed frame 1 through four chutes 101, the inner wall of the ventilation pipe 2 is fixedly connected with a filter screen 4, and the inner wall of the ventilation pipe 2 is slidably connected with a large particle filter plate 5;

[0046] Ventilation mechanism, the ventilation mechanism is arranged inside the ventilation pipe 2 to suck out the air in the workshop;

[0047] Cleaning mechanism, the cleaning mechanism is arranged on the side end of the filter screen 4 for cleaning the filter screen 4;

[0048] Limiting mechanism, the limiting mechanism is arranged on the side end of the large particle filter plate 5 to limit the large p...

Embodiment 2

[0051] For details, please refer to Figure 1-7 , a kind of ventilation equipment for the production workshop of electric wire plastic sheath, including,

[0052] The fixed frame 1, the upper and lower inner walls of the fixed frame 1 are cut with two chutes 101;

[0053] Ventilation pipe 2, the ventilation pipe 2 is slidably connected to the interior of the fixed frame 1 through four chutes 101, the inner wall of the ventilation pipe 2 is fixedly connected with a filter screen 4, and the inner wall of the ventilation pipe 2 is slidably connected with a large particle filter plate 5;

[0054] Ventilation mechanism, the ventilation mechanism is arranged inside the ventilation pipe 2 to suck out the air in the workshop;

[0055] Cleaning mechanism, the cleaning mechanism is arranged on the side end of the filter screen 4 for cleaning the filter screen 4;

[0056] Limiting mechanism, the limiting mechanism is arranged on the side end of the large particle filter plate 5 to limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com