Top cutting pressure relief equipment and top cutting pressure relief method

A technology of roof cutting, pressure relief and equipment, which is applied in earth square drilling, ground mining, underground mining, etc., which can solve the problems of large space occupation, low work efficiency, and many personnel, and achieve small space occupation, few personnel, and improved work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings. Wherein the same parts are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer" ” refer to directions towards or away from the geometric center of a particular part, respectively.

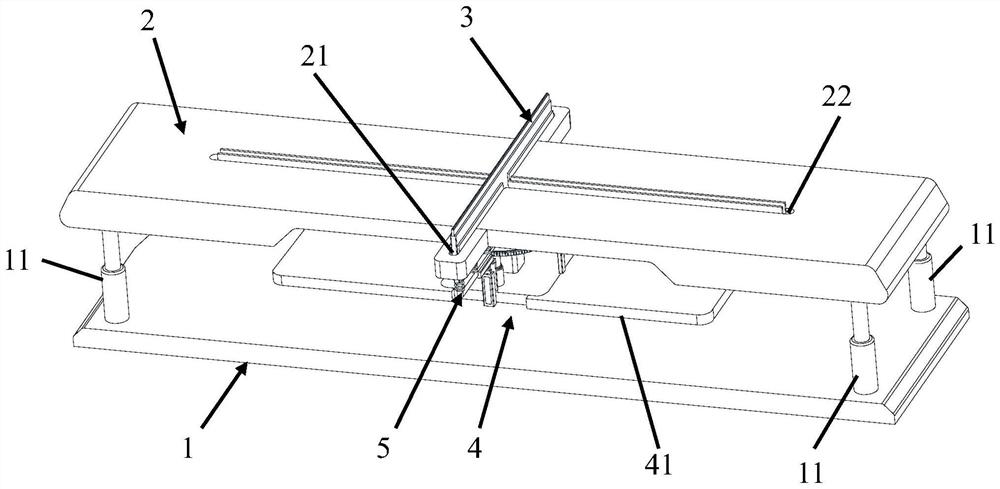

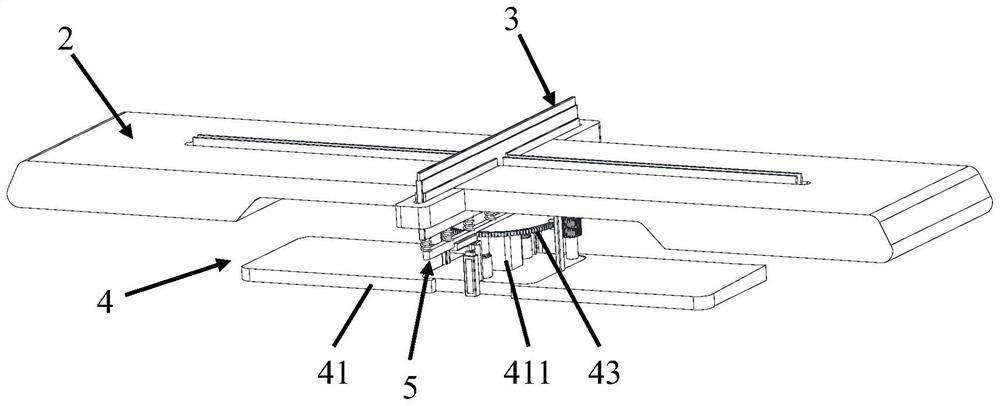

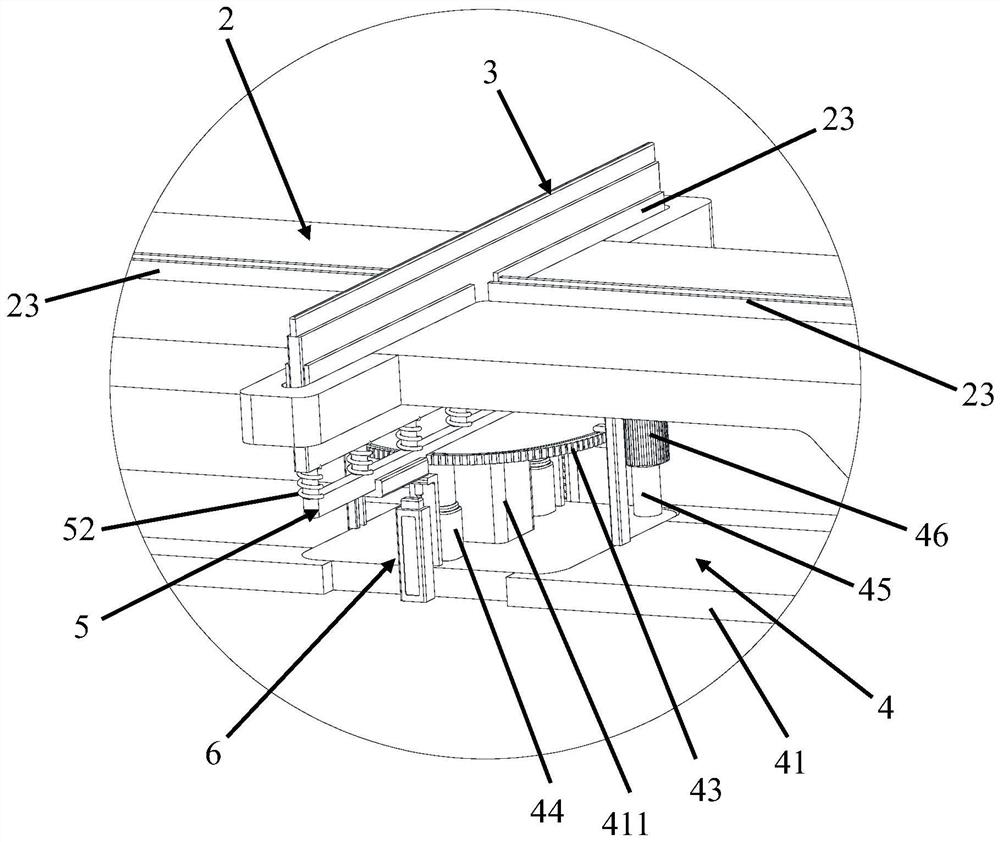

[0058] like Figure 1-5As shown, the top cutting and pressure relief device provided by an embodiment of the present invention includes a base 1 , a lifting top plate 2 , a blade plate 3 and a lifting and rotating drive mechanism 4 for driving the blade plate 3 to lift and rotate.

[0059] A first oil cylinder 11 is connected between the lift top plate 2 and the base 1. The lift top plate 2 has a first through hole 21 and a second through hole 22 for the blade 3 to pass through. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com