Inner folding hinge structure

A technology of folding hinges and hinges, which is applied in the field of hinges, can solve problems such as the inability to close the door, inconvenient installation, and affect the opening and closing of the door, so as to save replacement costs, save disassembly time, and improve convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

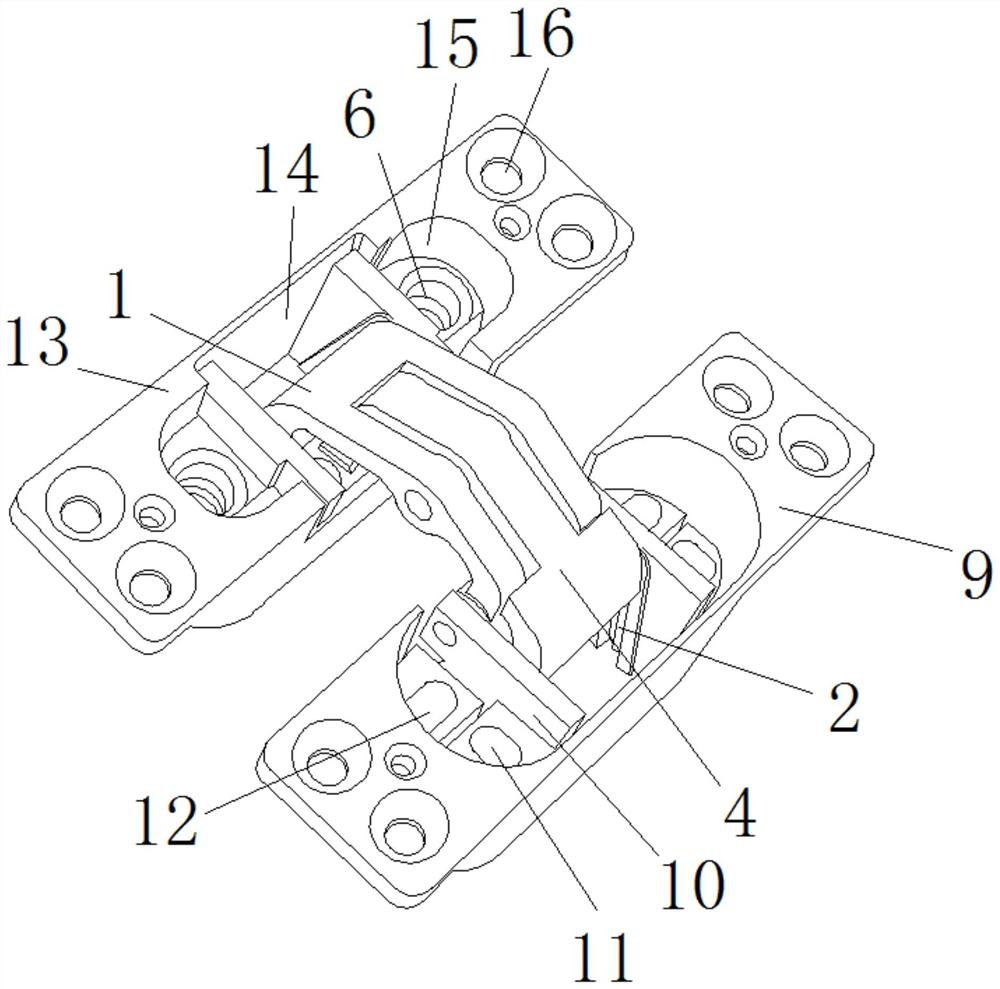

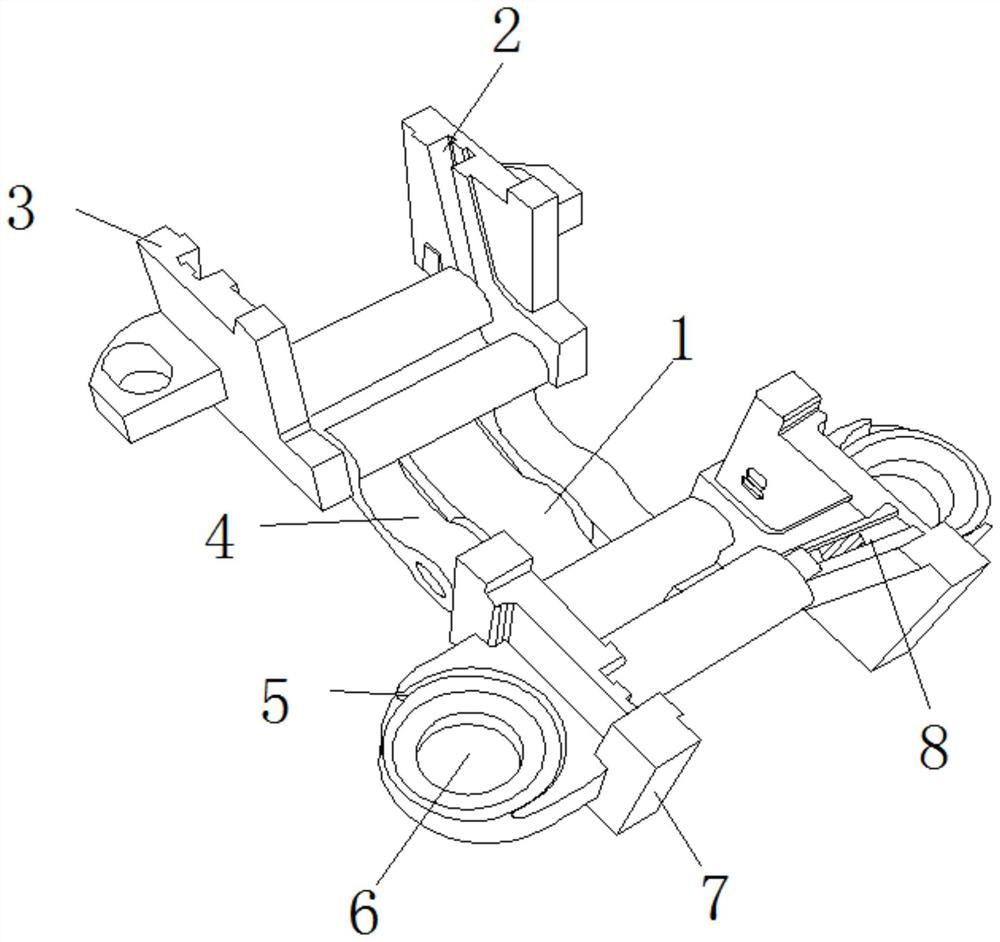

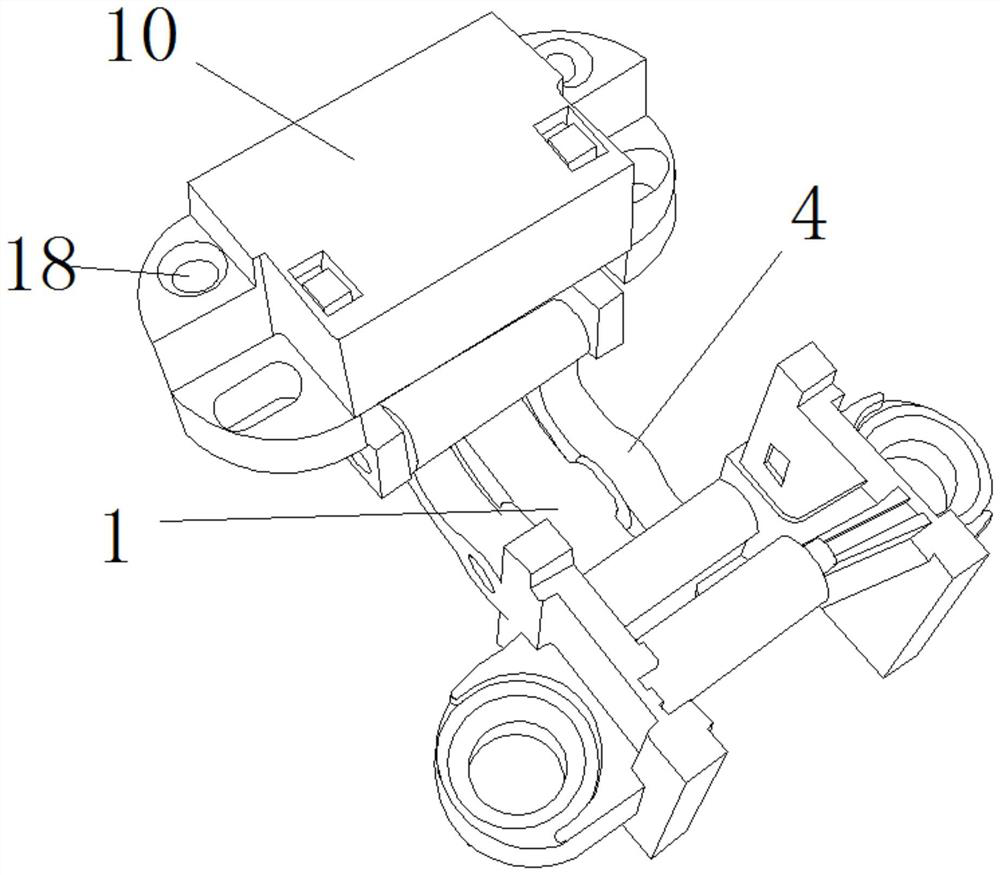

[0034] Example 1, as Figure 1-5 As shown, in the process of assembling the hinge, first install the rocker arm A1 inside the chute C8, install the rocker arm B4 inside the chute A2, and then install the housing 10 between the two sets of connecting plates A3, and Screw the bolt into the fixing hole B18 to connect the housing 10 with the chute A2, put the housing 10 into the storage compartment A9 and tighten the screw, then screw the screw into the adjusting hole A6 to make the sliding The slot B7 is connected to the storage bin B13. At this time, make holes on the door frame and the door leaf. At the same time, install the storage bin B13 on the door leaf, and install the storage bin A9 on the door frame. Finally, screw the screws into the inside of the lock hole 16. , and then fix the placement bin A9 and the placement bin B13.

Embodiment 2

[0035] Example 2, as Figure 1-5 As shown in the figure, when the door gap for installing the door leaf is too large, rotate the bolt inside the adjustment hole A6, and then adjust the front and rear of the door leaf, and then adjust the size of the door gap to prevent the door from being unable to close normally. When the installed door is inclined, Loosen the bolts inside the adjustment hole B11 and the adjustment hole C12, and pull out or push the housing 10 to adjust the left and right of the door leaf. When the adjustment is completed, lock the bolts, and finally open and close the door leaf repeatedly for testing. , and when the door leaf is closed, the rocker arm A1 and the rocker arm B4 slide inside the chute C8 respectively. When the door leaf is completely closed, the rocker arm A1 and the rocker arm B4 will be pushed into the storage compartment B13 and the storage compartment A9. The interior is hidden to prevent it from contacting the outside world.

[0036] Work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com