Round inclined column formwork supporting method

A formwork support and inclined column technology, which is applied to the on-site preparation of formwork/formwork/work frame, pillars, and building components, etc., can solve the problems of damage to the ground and steel pipes, insufficient support, and small contact area. Good force, prevent deformation, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments.

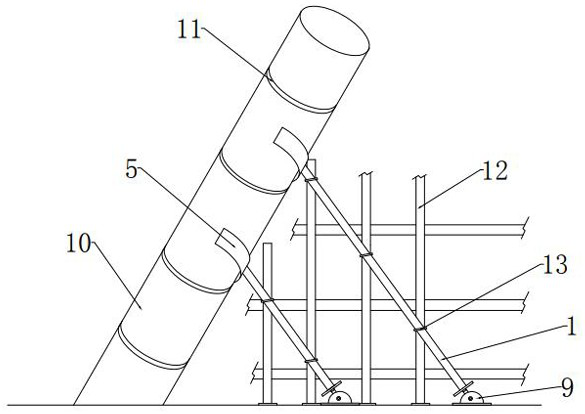

[0027] like figure 1 As shown, a kind of circular inclined column formwork support method proposed by the present invention is carried out according to the following steps:

[0028] S1. Measure the line and mark the 12 position of the vertical support and the position of the diagonal support according to the installation requirements of the formwork.

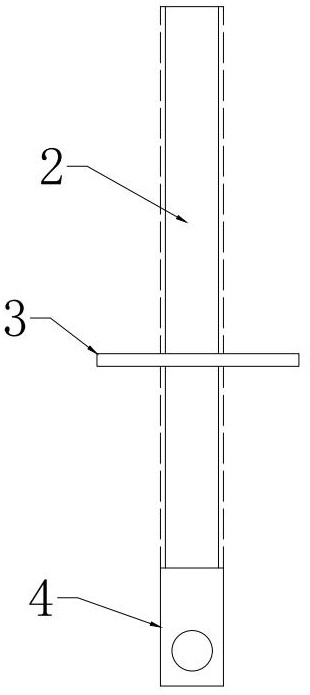

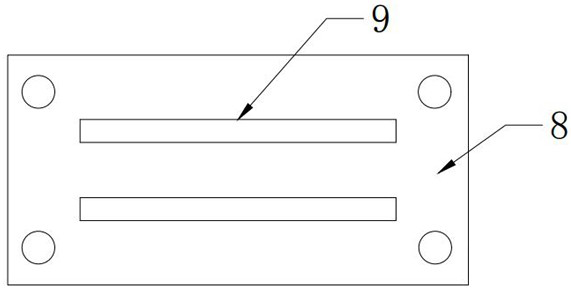

[0029] S2. The adjusting device is composed of a screw 2, a nut 3 and a connecting piece 4. The other end of the support pipe 1 is fitted with a screw 2, and the screw 2 is threadedly connected with a nut 3. The bottom end of the support pipe 1 abuts on the nut 3. like figure 2 As shown, the end of the screw 2 is connected with the connecting piece 4, and the connecting piece 4 is provided with a through hole. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com