Construction method for underwater positioning of embedded rock-socketed foundation steel pipe pile

A construction method and technology for steel pipe piles, which are applied in basic structure engineering, sheet pile walls, buildings, etc., can solve the problems of difficulty in ensuring installation accuracy, heavy steel pipe piles, and difficulty in construction, and achieve high installation accuracy and construction. The effect of simplicity and simplification of the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

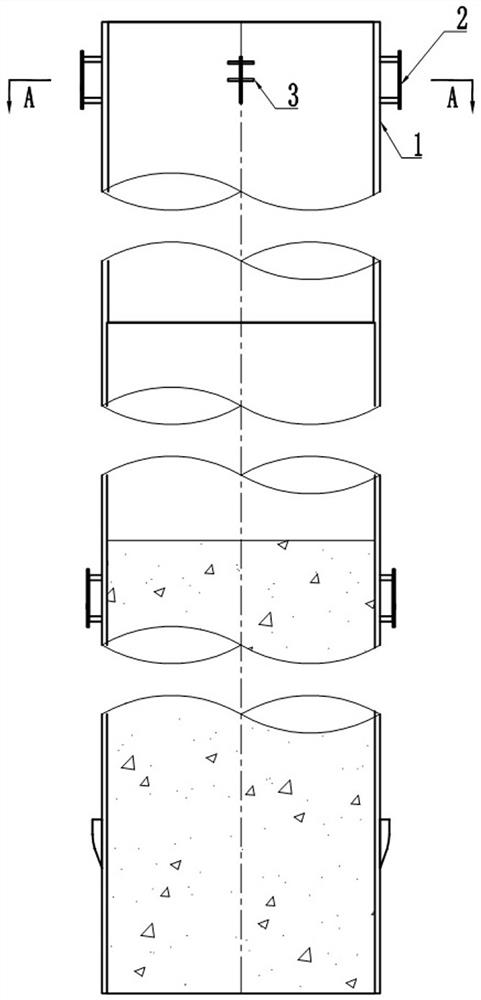

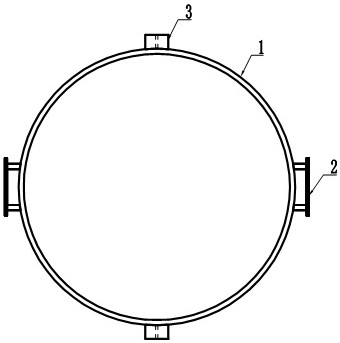

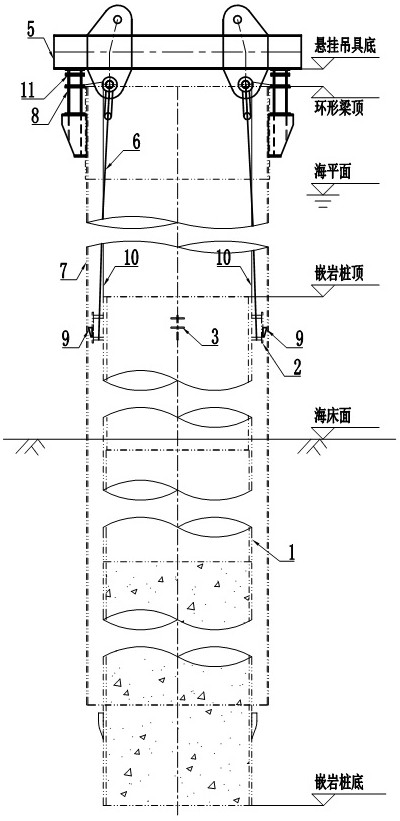

[0028] combined with Figure 1-8 , an implementation manner of a construction method for underwater positioning of steel pipe piles implanted in rock-socketed foundations:

[0029] A. A pair of main lifting lugs 2 are symmetrically welded on the left and right outer side walls of the upper part of the steel pipe pile 1, and a pair of limit devices 3 are symmetrically welded on the front and rear outer side walls of the upper part of the steel pipe pile 1. The positioning device 3 is on the same horizontal plane; the two main lifting lugs 2 and the two limiting devices 3 together constitute the steel pipe pile positioning device;

[0030] B. The upper end of the hoisting wire rope 12 is hung on the floating hook 13 before the hoisting, and the lower end of the hoisting wire rope 12 is fixed on the hanging lug 14 of the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com