Foam scrubbing agent composition as well as preparation method and application thereof

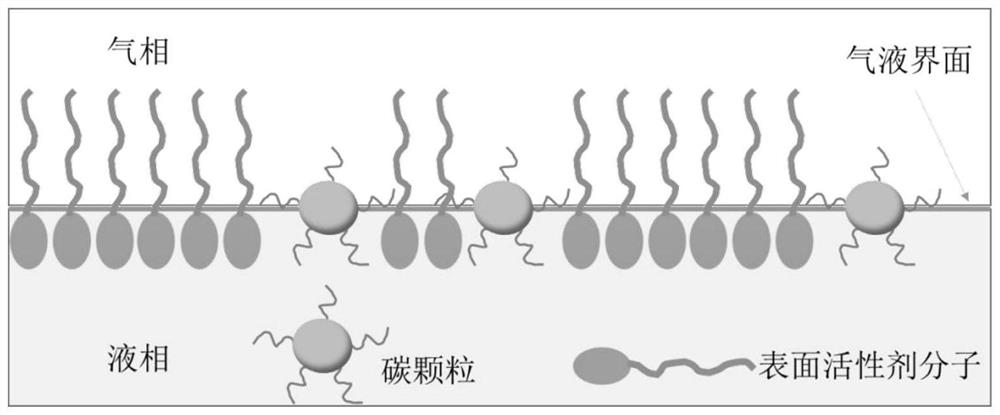

A technology of composition and foam discharge agent, which is applied in the directions of drilling composition, carbon preparation/purification, chemical instruments and methods, etc., can solve the problems of high cost and complicated preparation process of nano-particles, and achieves low cost and high structure. The effect of green environmental protection and half-life slowing down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

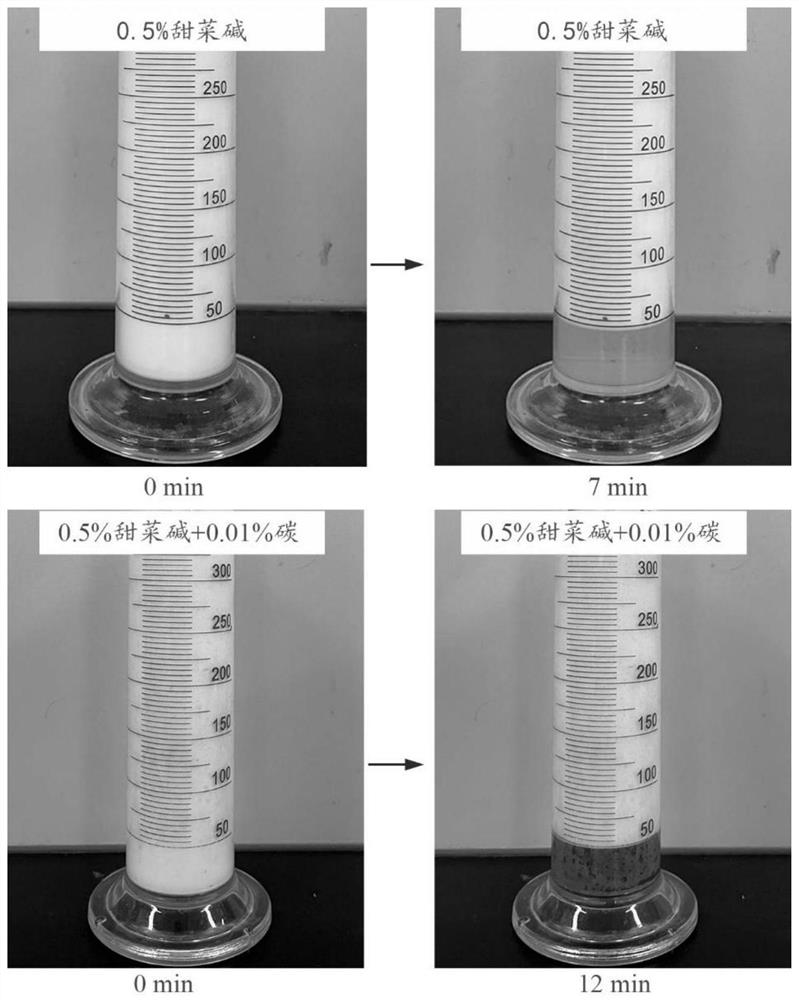

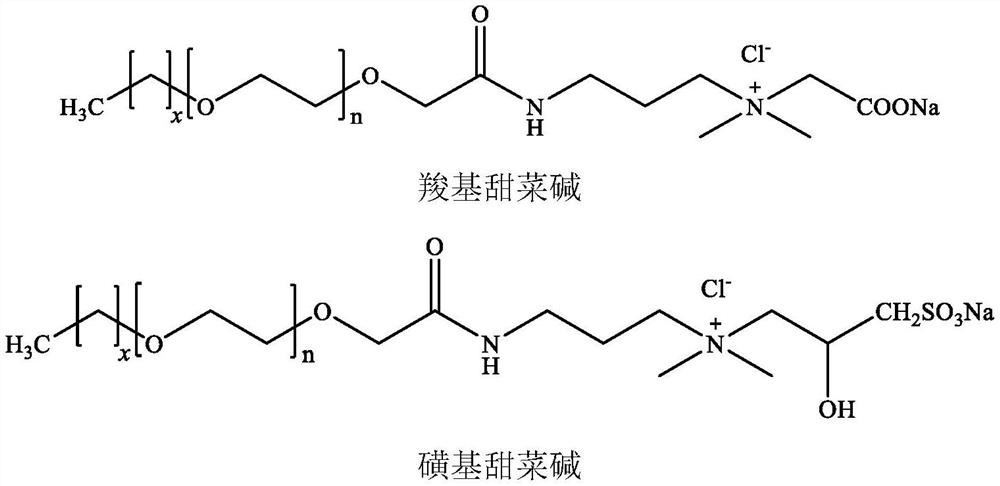

[0033] Under the conditions of normal temperature and pressure, take carboxybetaine (x=11, n=6), prepare the carboxybetaine solution of 0.5% concentration, add rice husk according to the mass ratio of carboxybetaine and rice husk-derived carbon particles 50:1 The carbon particles are derived and mixed to obtain a foam release agent composition.

[0034] The preparation method of rice husk-derived carbon particles of this embodiment: the naturally air-dried rice husks are placed in a tube furnace, and the 2 The temperature was raised to 700°C under protective conditions (the heating rate was 10°C / min), and then calcined at a constant temperature of 700°C for 2 hours. After natural cooling, the rice husk biochar was obtained; the rice husk biochar was placed in a ball mill (including 14 Small steel balls with a diameter of 6.35 mm and 8 large steel balls with a diameter of 9.5 mm), uniformly pulverized for 30 minutes at 300 Hz to obtain rice husk-derived carbon powder with a par...

Embodiment 2

[0037] Under the condition of normal temperature and pressure, take carboxybetaine (x=13, n=8), prepare the carboxybetaine solution of 0.5% concentration, add rice husk according to the mass ratio of carboxybetaine and rice husk-derived carbon particles 10:1 The carbon particles are derived and mixed to obtain a foam release agent composition.

[0038] The preparation method of rice husk-derived carbon particles of this embodiment: the naturally air-dried rice husks are placed in a tube furnace, and the 2 The temperature was raised to 700°C under protective conditions (the heating rate was 10°C / min), and then calcined at a constant temperature of 700°C for 2 hours. After natural cooling, the rice husk biochar was obtained; the rice husk biochar was placed in a ball mill (including 14 Small steel balls with a diameter of 6.35mm and 8 large steel balls with a diameter of 9.5mm), uniformly pulverized for 25 minutes at 300Hz to obtain a rice husk-derived carbon powder with a parti...

Embodiment 3

[0041] Under normal temperature and pressure conditions, take carboxybetaine (x=15, n=10), prepare a 0.5% concentration of carboxybetaine solution, add rice husk according to the mass ratio of carboxybetaine and rice husk-derived carbon particles 5:1 The carbon particles are derived and mixed to obtain a foam release agent composition.

[0042] The preparation method of rice husk-derived carbon particles of this embodiment: the naturally air-dried rice husks are placed in a tube furnace, and the 2 The temperature was raised to 700°C under protective conditions (the heating rate was 10°C / min), and then calcined at a constant temperature of 700°C for 2 hours. After natural cooling, the rice husk biochar was obtained; the rice husk biochar was placed in a ball mill (including 14 Small steel balls with a diameter of 6.35mm and 8 large steel balls with a diameter of 9.5mm), uniformly pulverized for 25 minutes at 300Hz to obtain a rice husk-derived carbon powder with a particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com