EBS shaft module pressure control method based on high-frequency PWM

A technology of pressure control and shaft module, which is applied in the direction of brakes, brake transmission devices, vehicle components, etc., can solve the problems of large overshoot, low control precision, and poor brake pedal feel, and achieve shortened braking distance and reduced The effect of long decompression process and avoiding overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

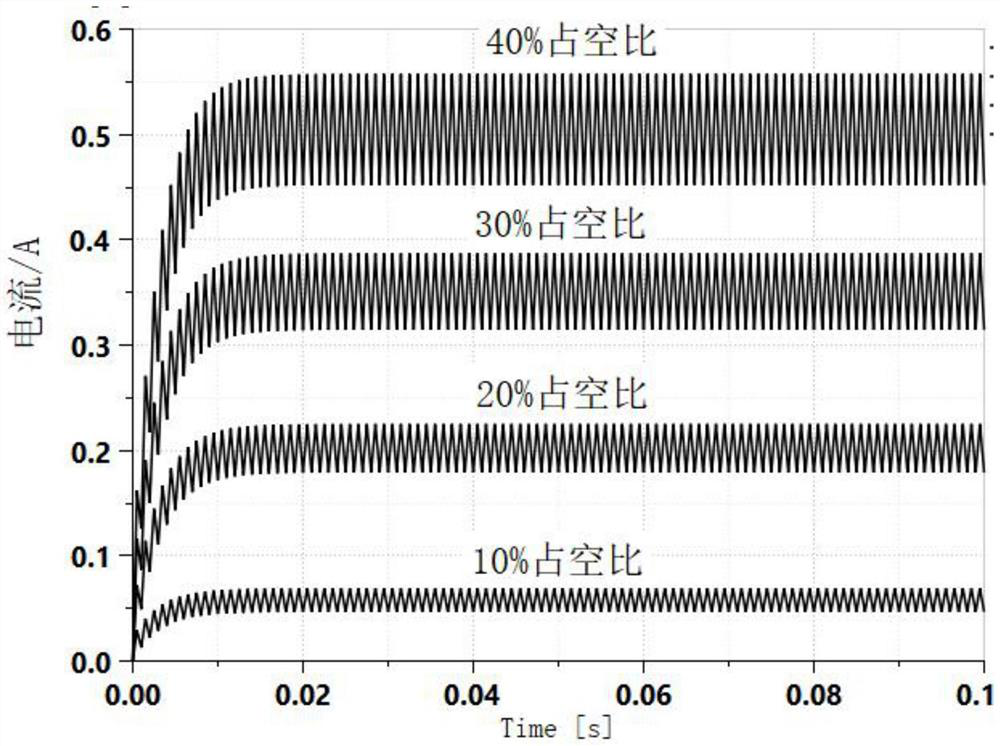

[0037] The invention provides an EBS shaft module pressure control method based on high-frequency PWM. The method realizes switching of the solenoid valve by adjusting the duty ratio of the high-frequency PWM signal and simultaneously considering the influence of the inlet and outlet pressure difference on the valve core opening. It has the function of flow regulation to achieve the purpose of accurately controlling the pressure of the brake air chamber.

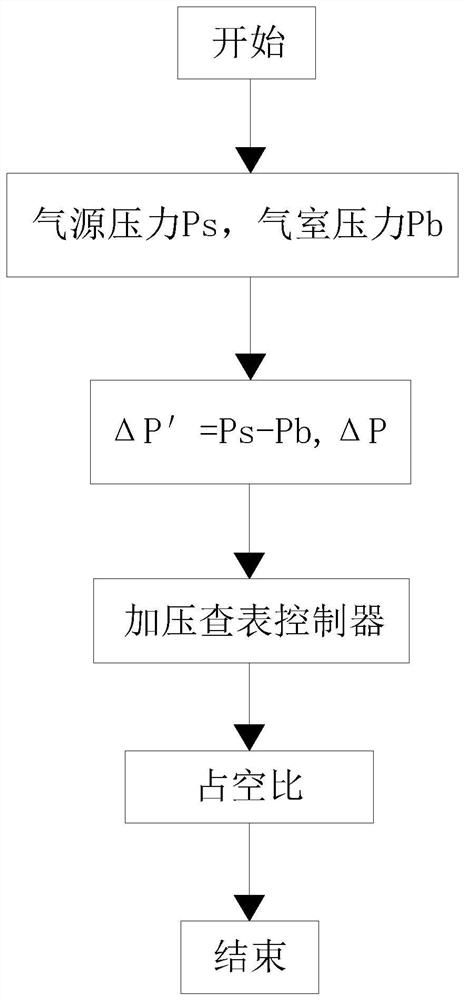

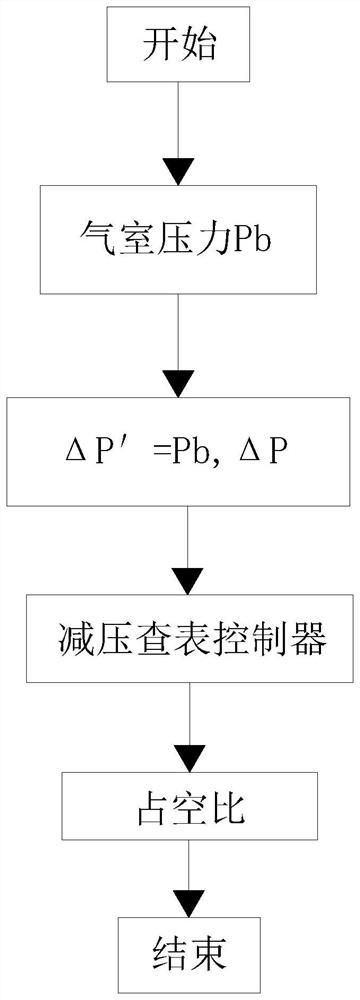

[0038] The control method is realized through the following steps:

[0039] First collect the target pressure value P output by the foot brake valve t and the current actual pressure P output by the brake chamber pressure sensor b , the difference between the two is used to calculate the pressure difference ΔP.

[0040] According to the calculated differential pressure ΔP, determine the state that the axis module needs to enter. When ΔP≥0.1bar, the axis module enters the pressurized control state, and outputs a high-frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com