Uninterrupted circulating type concrete automatic transporting, lifting and distributing system and method

A technology of distributing system and hoisting system, which is applied to unloading devices, manufacturing tools, supplying devices, etc., can solve the problems of uninterrupted and cyclical distribution of concrete, and inability to meet the requirements of large-volume concrete pouring, so as to avoid mutual interference, Compact structure, the effect of reducing the overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

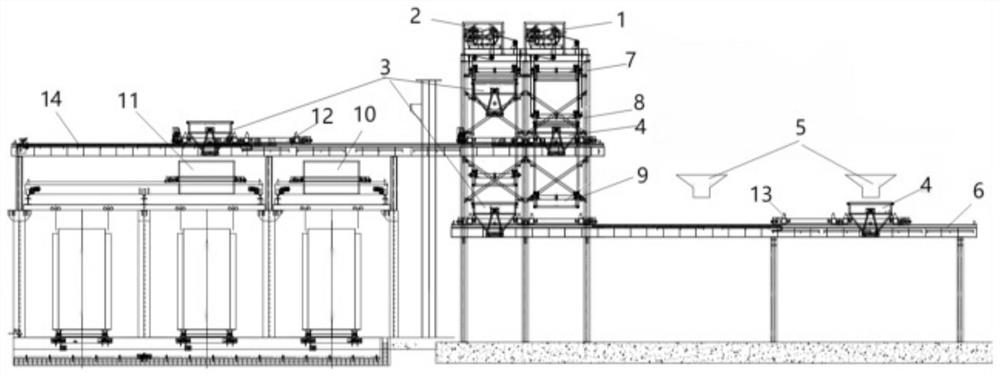

[0044] For pipeline operations, such as figure 1 The conveying direction of the conveying hopper shown is the basic direction, which is used to determine the front and rear directions of the system. Specifically, the direction in which the material (concrete) flows is forward, otherwise it is backward, and front and rear correspond to head and tail.

[0045] This embodiment provides an uninterrupted circulating concrete automatic transportation and lifting system, such as figure 1 As shown, it includes a first conveying track 6, a second conveying track 14, at least two lifting systems, at least two distributing systems, and at least two conveying hoppers. For the high height of the prefabricated components, at least two lifting systems are provided to transport the Hopper lifting; at least two distribution systems can guarantee the amount of concrete poured.

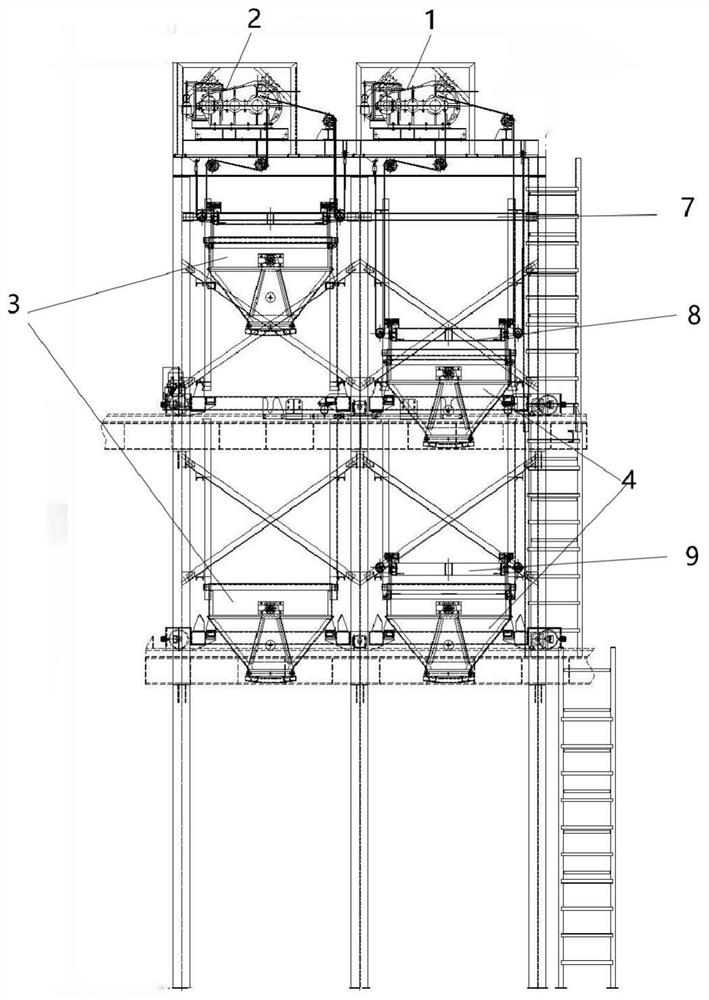

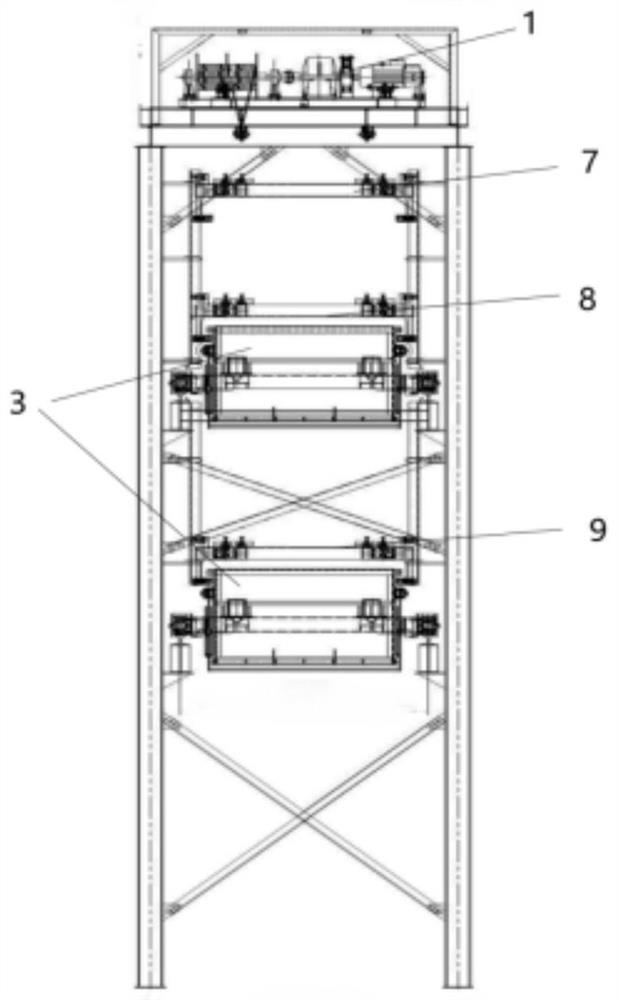

[0046] Preferably, there are two hoisting systems, namely the first hoisting system 1 and the second hoisting system...

Embodiment 2

[0070] The present embodiment provides an uninterrupted circulation type automatic transportation, lifting and distributing method for concrete, using the automatic transportation, lifting and distributing system described in the first embodiment, including the following steps:

[0071] Step 1: After the first conveying hopper 3 receives the material at the discharge port 5 of the mixing station, the first conveying vehicle 13 drives to the bottom of the lifting system, and the second lifting system 2 hangs the first conveying hopper 3 to the first working position. 7 Wait, the second conveying vehicle 12 goes under the lifting system, the hanger of the second lifting system 2 places the first conveying hopper 3 on the second conveying vehicle 12, and the second conveying vehicle 12 leaves the lifting system and goes to the distribution system.

[0072] Step 2: The hanger of the first lifting system 1 is lowered to the third work position 9 to wait, and the hanger of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com