Chain guide mechanism

A guiding mechanism and chain technology, which is applied to belts/chains/gears, mechanical equipment, engine components, etc., can solve problems such as poor workability, improve workability, improve workability, and avoid deterioration of fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

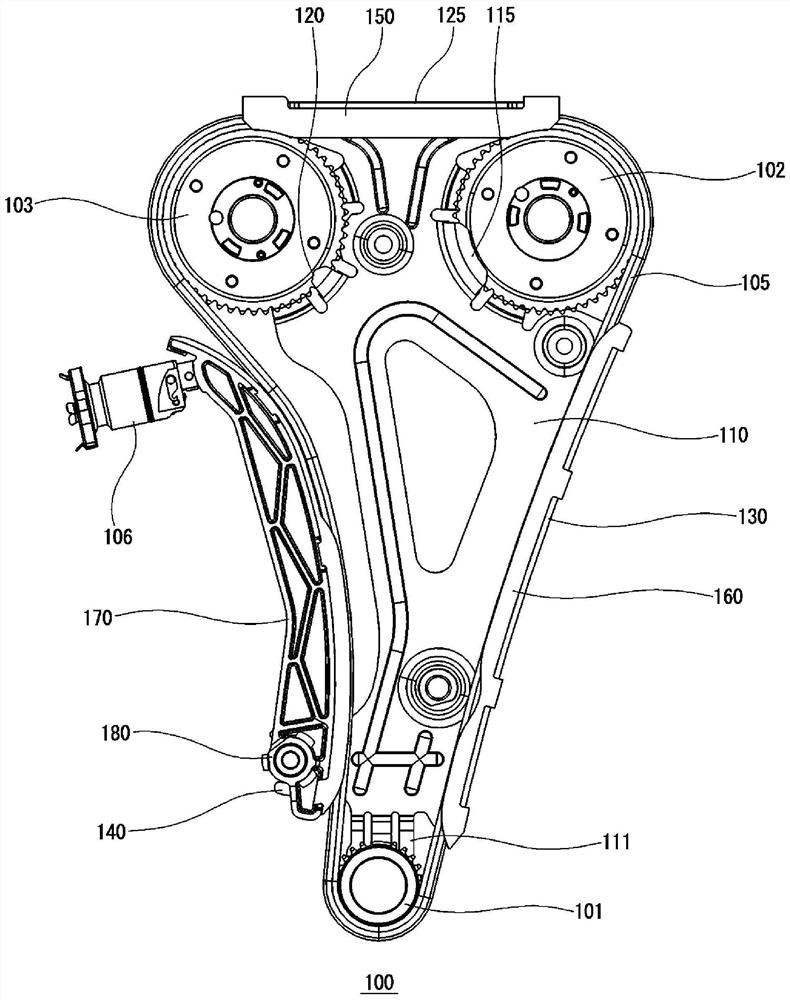

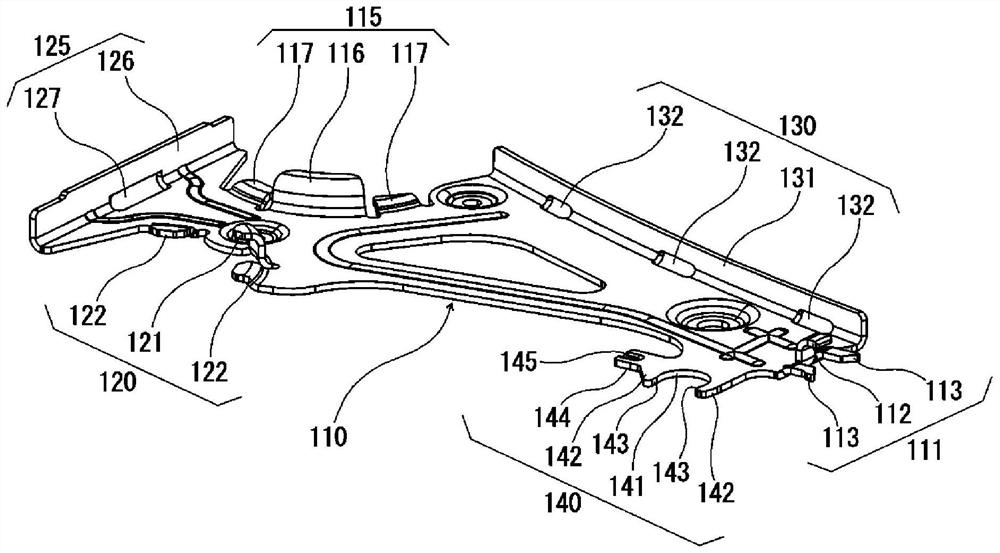

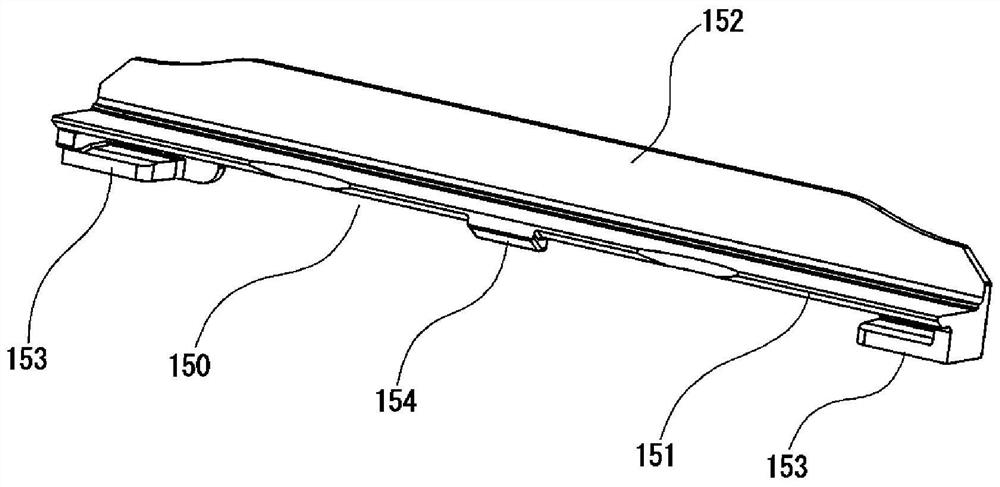

[0035]The present invention is a chain guide mechanism capable of integrally supporting constituent elements including a plurality of sprockets, a chain wound around the plurality of sprockets, and a fixing for sliding and guiding the chain by a frame. The specific embodiment of the chain guide and the swing chain guide may be arbitrary as long as the swing chain guide includes a cylinder protruding outward from one of the side surfaces in the width direction of the guide. The frame is provided with a sprocket support part for supporting the plurality of sprockets by winding the chain; a fixed chain guide support part for supporting the fixed chain guide; and a swinging The chain guide holding portion holds the mounting boss portion in a dummy fitting state, and the rocking chain guide holding portion is configured to be able to extend from the side along one of the side surfaces of the rocking chain guide. Insert the mounting sleeve part.

[0036] The chain moving surfaces o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com