Spring pin type radial well guider layer changing device

A guider and radial well technology, applied in directional drilling, drilling with liquid/gas jets, etc., can solve problems such as high cost, labor and time consumption, and save time, reduce labor, and reduce construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be described in further detail below with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than an exhaustive list of all the embodiments. Also, the embodiments of the present invention and the features of the embodiments may be combined with each other without conflict.

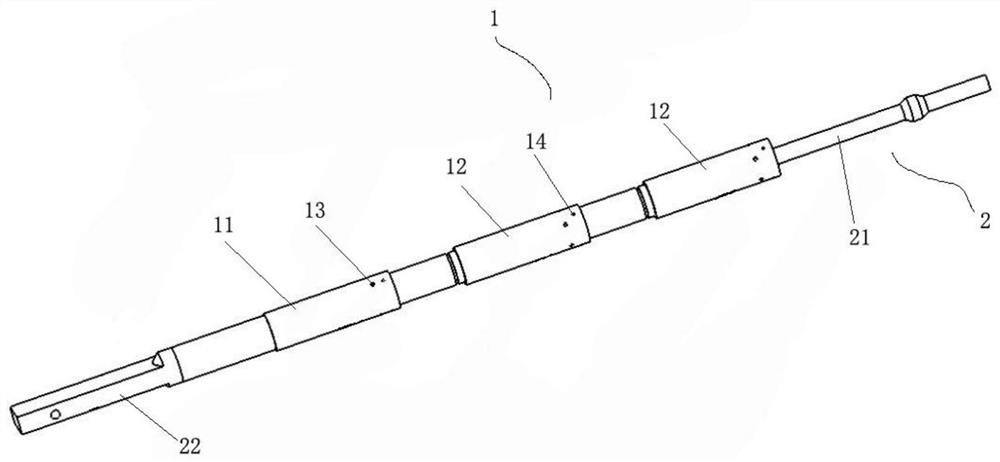

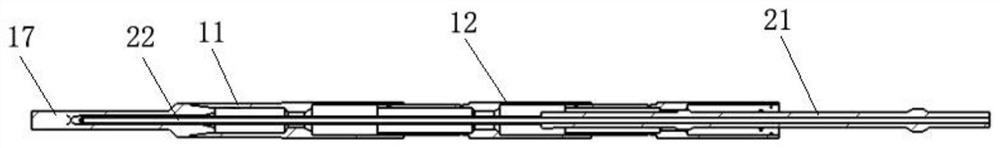

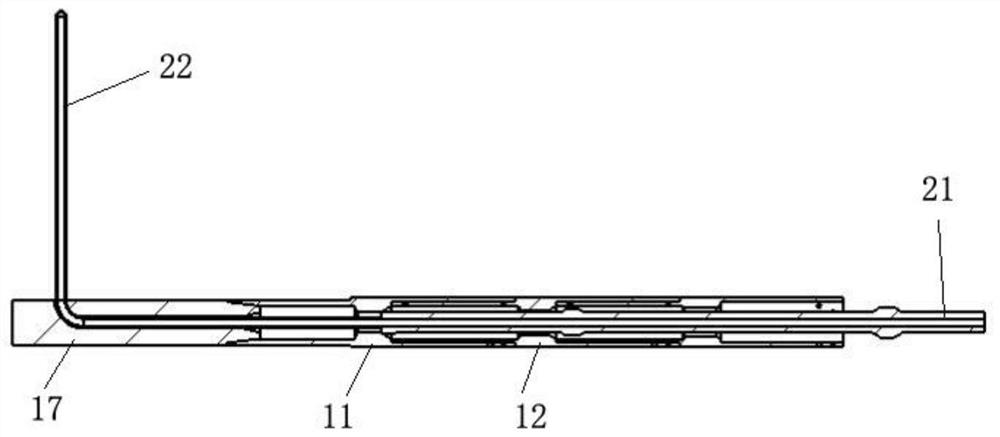

[0039] figure 1 A spring-pin radial well guide layer changing device according to an embodiment of the present invention is schematically shown, including a guide outer pipe 1 and a tool string 2 . The guide outer pipe 1 includes an oil pipe, a multi-stage layer changer connected below the oil pipe, and a guide 17 connected at the lower end of the multi-stage layer changer. The tool string 2 passes through the outer guide tube 1 and protrudes along the radial di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com