Torsional vibration damper with torque limiter

A technology of torque limiter and torsional vibration damper, applied in the direction of spring/shock absorber, rotational vibration suppression, vibration suppression adjustment, etc. The effect of simplified removal and re-installation, simplified uninstallation and re-installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

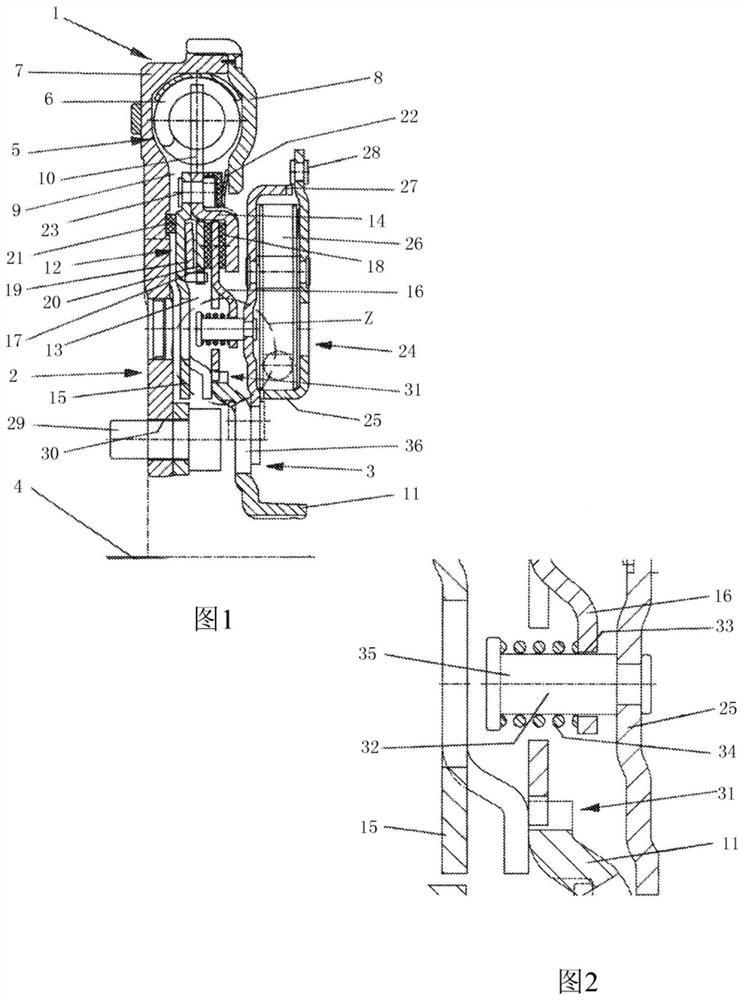

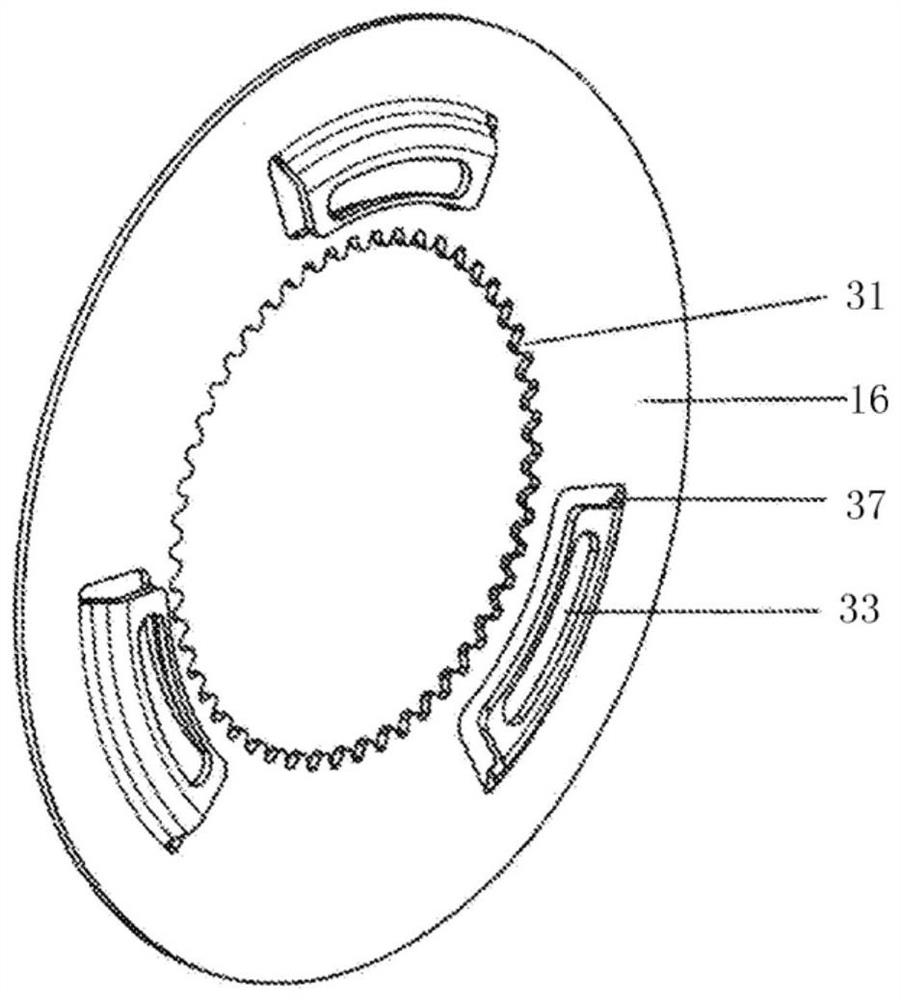

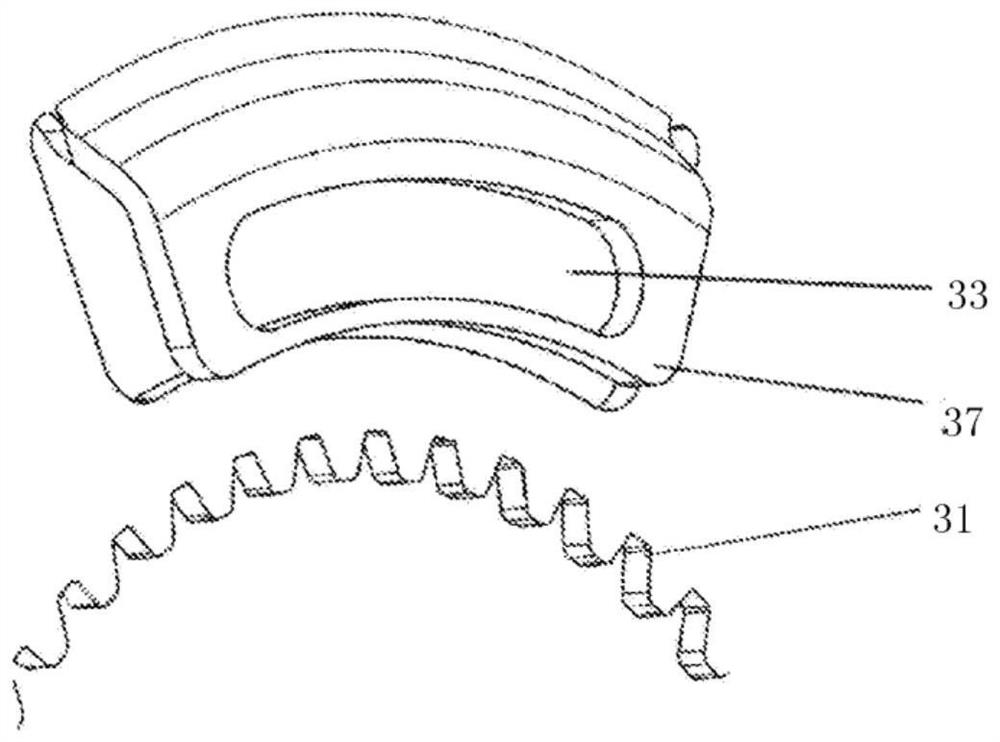

[0026] figure 1 By way of example, a torsional vibration damper 1 in the form of a dual-mass flywheel is shown, which has a primary part 2 and a secondary part 3 , which can be joined together about an axis of rotation 4 . Rotation and limited twist relative to each other. A spring damper arrangement 5 with a mechanical accumulator in the form of an arc spring 6 acts between the primary part 2 and the secondary part 3 . A torsional vibration damper 1 for a powertrain of a motor vehicle operating with an internal combustion engine, in particular for a DHT hybrid application, has the task of damping rotational inhomogeneities in the powertrain caused by the internal combustion engine.

[0027] The primary part 2 comprises a flange element 7 , which is connected radially outside in one piece to the primary cover 8 , which together enclose a spring space 9 which defines a spring space 9 for accommodating the arc spring 6 . In this case, the arc spring 6 is supported by one sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com