Power semiconductor device transient thermosensitive voltage testing device

A technology for power semiconductor and voltage testing, which is applied in the direction of single semiconductor device testing, measuring devices, voltage/current isolation, etc. Junction temperature test accuracy and other issues, to achieve the effect of small interference, small ripple interference, and stable waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

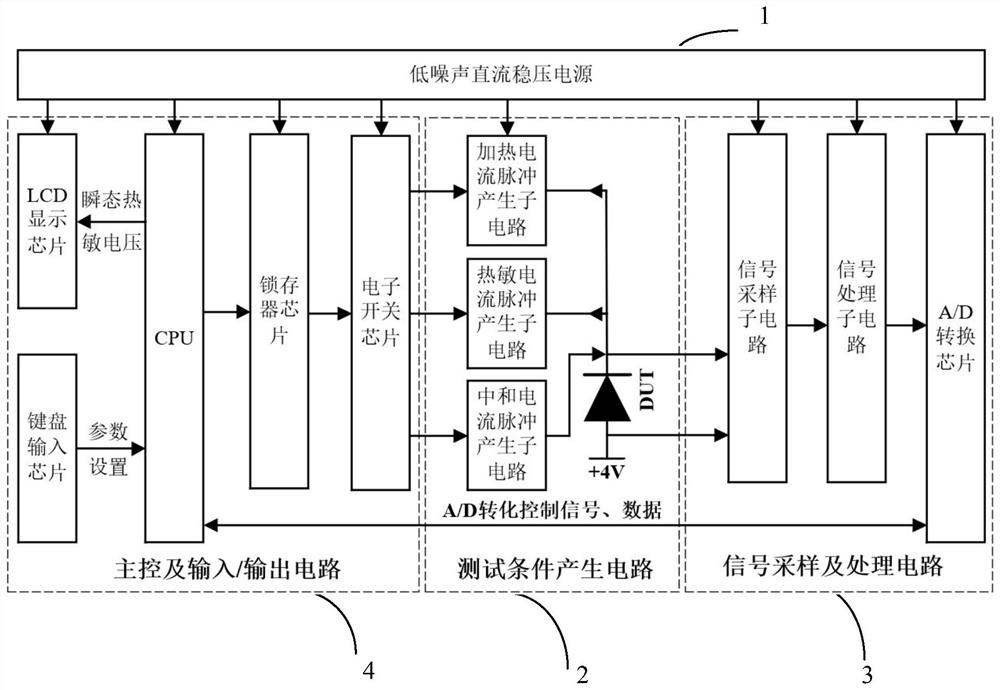

[0081] like figure 1 As shown, in the embodiment of the present invention, a power semiconductor device transient thermal voltage test device provided by the inventor is used on the tested power semiconductor device DUT, including a low-noise DC stabilized power supply 1 and its respectively connected Test condition generation circuit 2, signal sampling and processing circuit 3 and main control and input / output circuit 4; wherein,

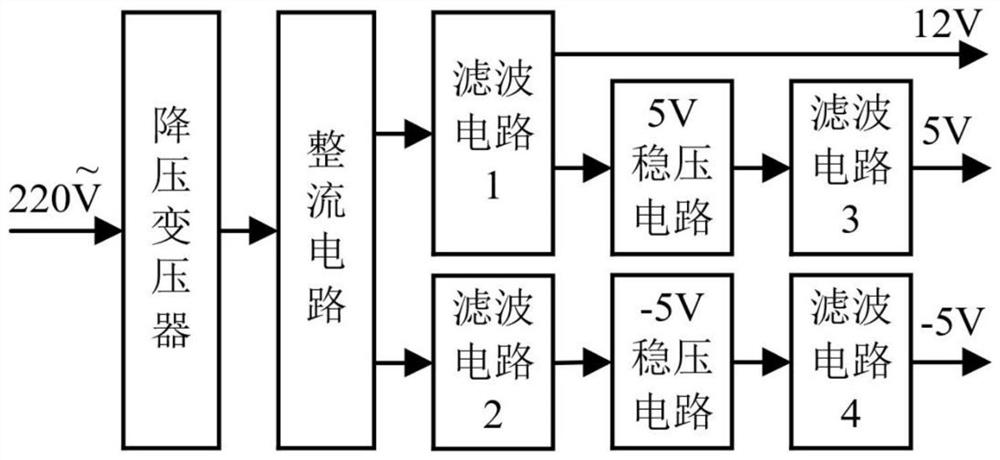

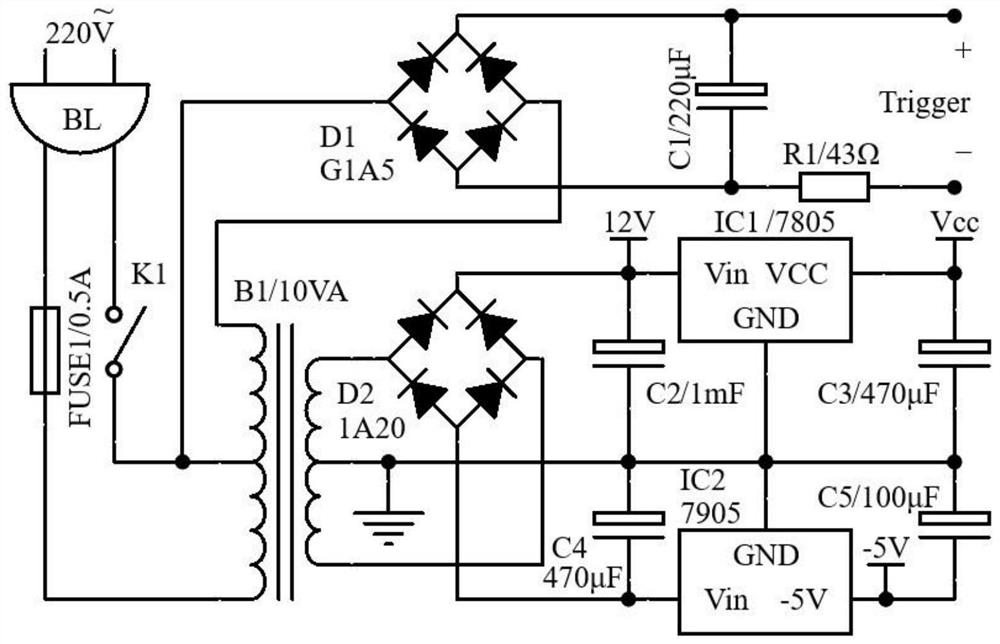

[0082]The low-noise DC regulated power supply 1 is connected to an external AC power supply (not shown), and is used to step down, rectify, filter, stabilize and filter the AC power, and then output a regulated DC power; wherein, the low-noise DC regulated power supply includes Step-down transformer, rectifier circuit, first filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com