Device and method for automatically and accurately positioning in touch screen and touch pen test equipment

A test equipment, precise positioning technology, applied in the direction of measuring device, measuring device casing, using optical device, etc., can solve the problem of no way to guarantee the probe, difference, relying on operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

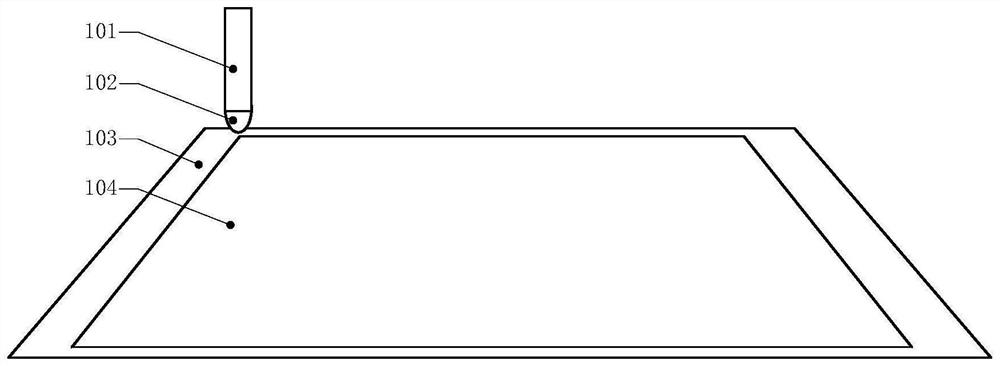

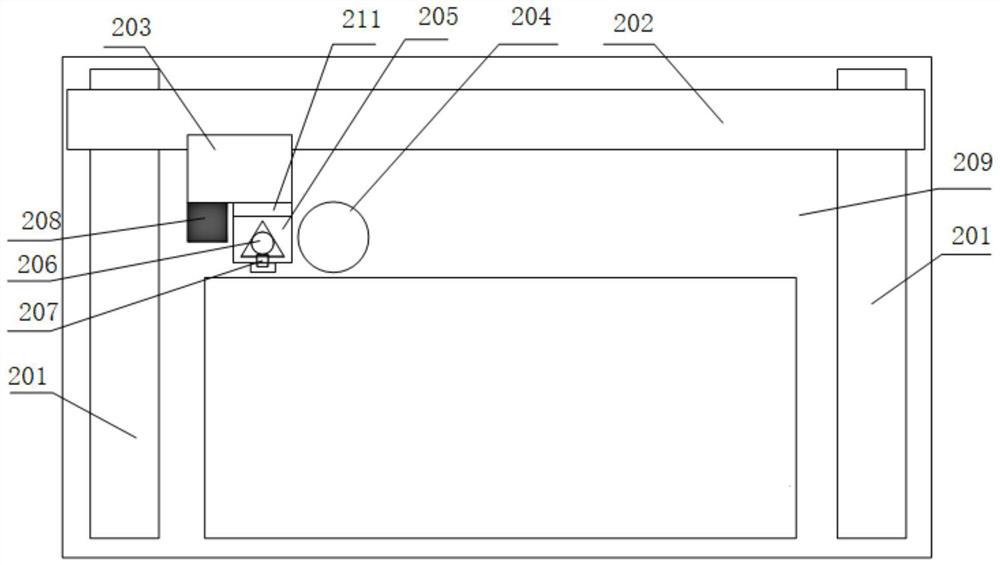

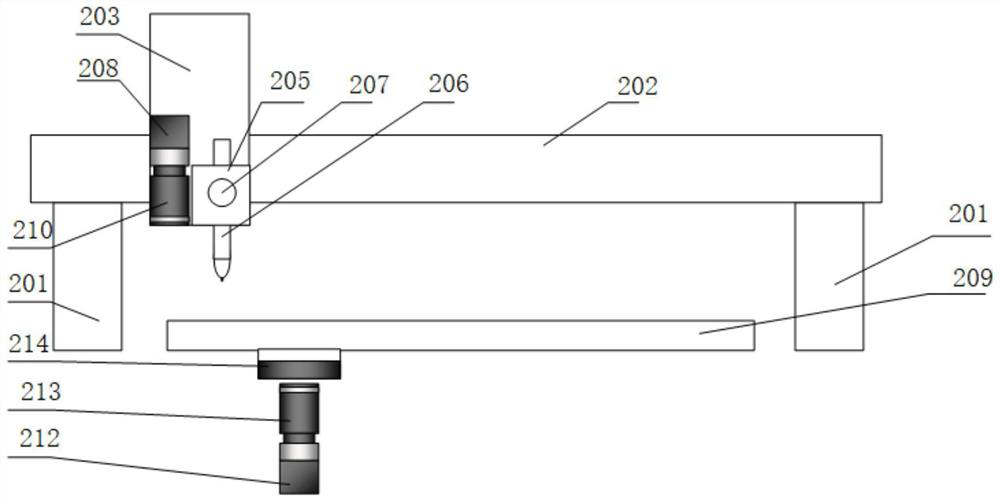

[0036] like Figure 2 to Figure 4 As shown, in this embodiment, a device for automatic and precise positioning in a touch screen and stylus pen test equipment is provided, including a test platform 209, a three-axis linear displacement mechanism, a touch screen vision system, a probe vision system, a pressure sensor The acquisition system, the angle rotation mechanism 211, the probe clamping mechanism and the data acquisition and processing control system; the three-axis linear displacement mechanism is erected above the test platform 209, and a touch screen is placed on the test platform 209. The screen vision system and the angle rotation mechanism 211 are both installed on the Z-axis 203 of the three-axis linear displacement mechanism and can slide up and down along it. The probe clamping mechanism is installed on the angle rotation mechanism 211. A probe 206 is installed on the head clamping mechanism; the test platform 209 is provided with light-transmitting holes 204 pen...

Embodiment 2

[0046] In this embodiment, a method for automatic and precise positioning in a touch screen and a stylus pen testing device is provided. The method is implemented by using the device of the first embodiment, and the method includes:

[0047] 1. The visual positioning method of the VA area of the touch screen; the touch screen is lit, the touch screen vision system moves along the X-axis 202, Y-axis 201, Z-axis 203 of the three-axis linear displacement mechanism to the set initial position, and starts taking pictures, image processing, and identification. A corner point 303 in the VA area 301 of the touch screen in the image, and calculate the coordinates of the corner point 303 and the deviation between the corner point 303 and the center of the image; if the deviation is not zero, it means the center of the field of view of the touch screen vision system If it does not coincide with the corner point 303, the touch screen vision system will automatically move in place along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com