Sandwich integrated insulation board suitable for zero-carbon building

A zero-carbon building and thermal insulation board technology, applied in construction, thermal insulation, building components, etc., can solve the problems of lack of stable butt joint structure, lack of connection structure, unfavorable construction, etc., to shorten the construction period, reduce construction waste, and reduce consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

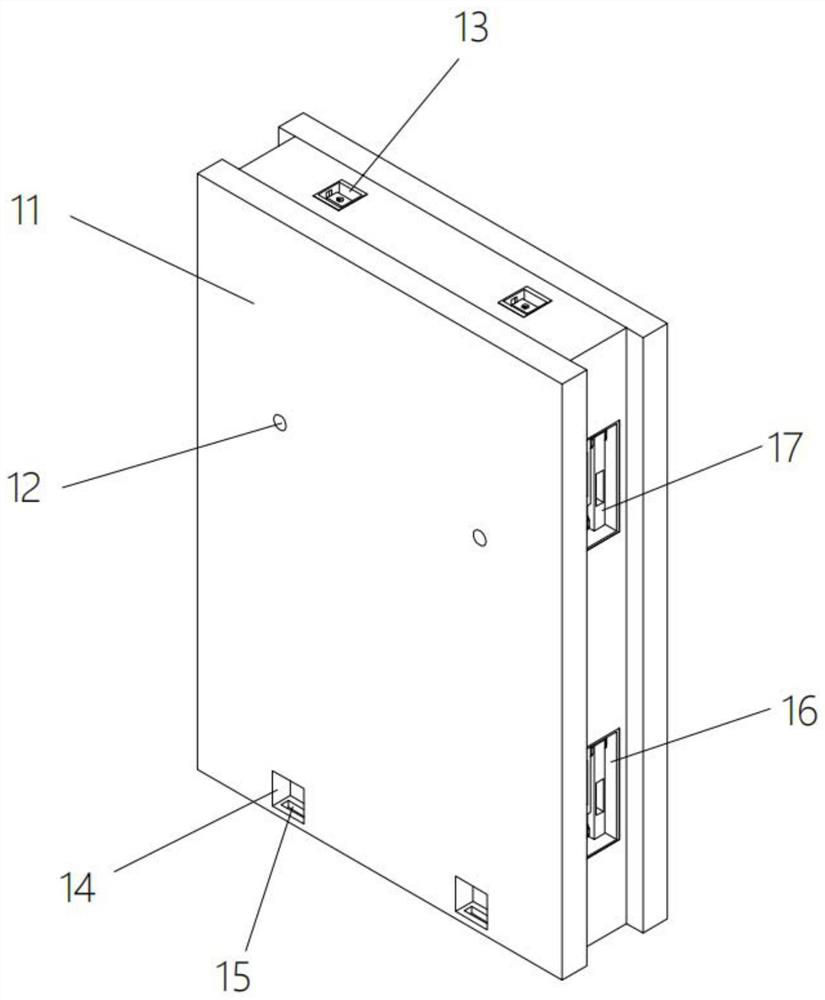

[0033] see Figure 1-Figure 8 In the embodiment of the present invention, a sandwich integrated thermal insulation board suitable for zero-carbon buildings includes two sets of substrates 11 and a thermal insulation board body 27 arranged between the two sets of substrates 11. The thermal insulation board body 27 is not connected to the substrate 11. The four groups of side walls in contact are connected with concrete seals;

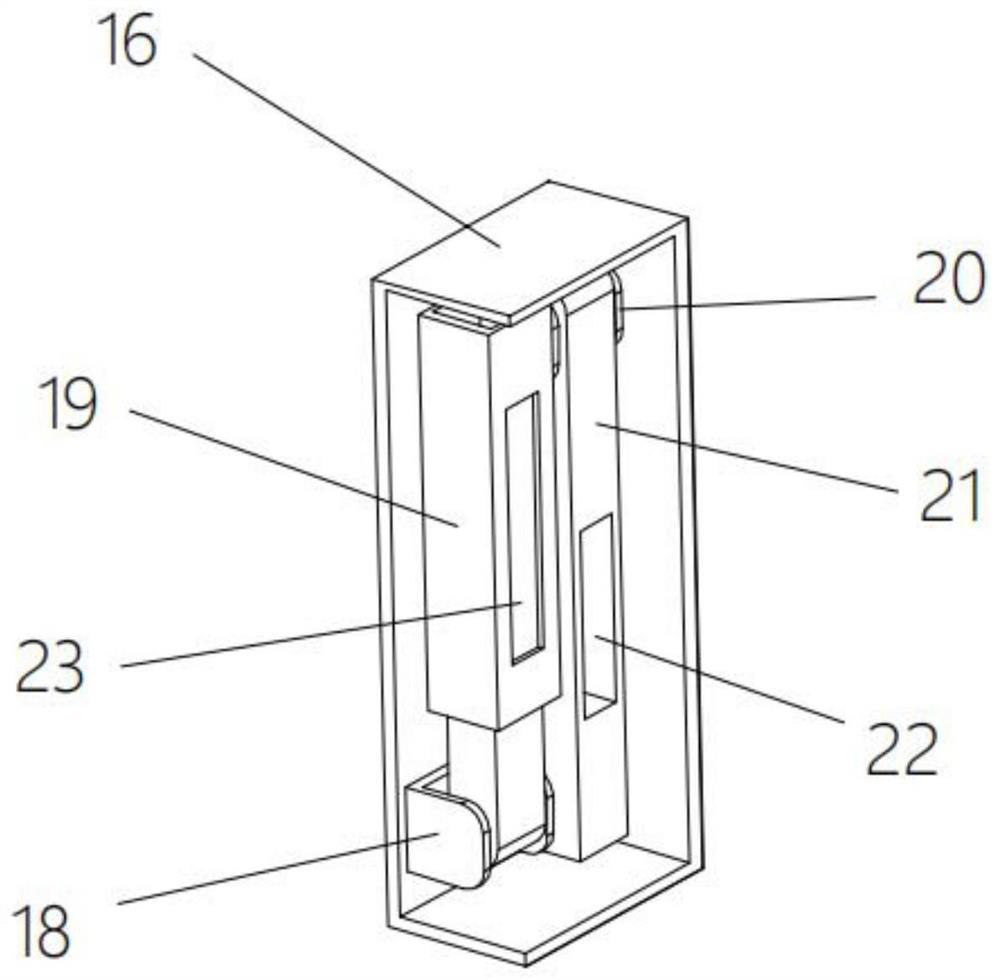

[0034] At least two sets of docking boxes 16 are provided on both sides of the thermal insulation board body 27, and the docking boxes 16 are provided with foldable docking pieces 17 for connection between adjacent thermal insulation integrated boards; the docking boxes 16 are poured in a concrete seal;

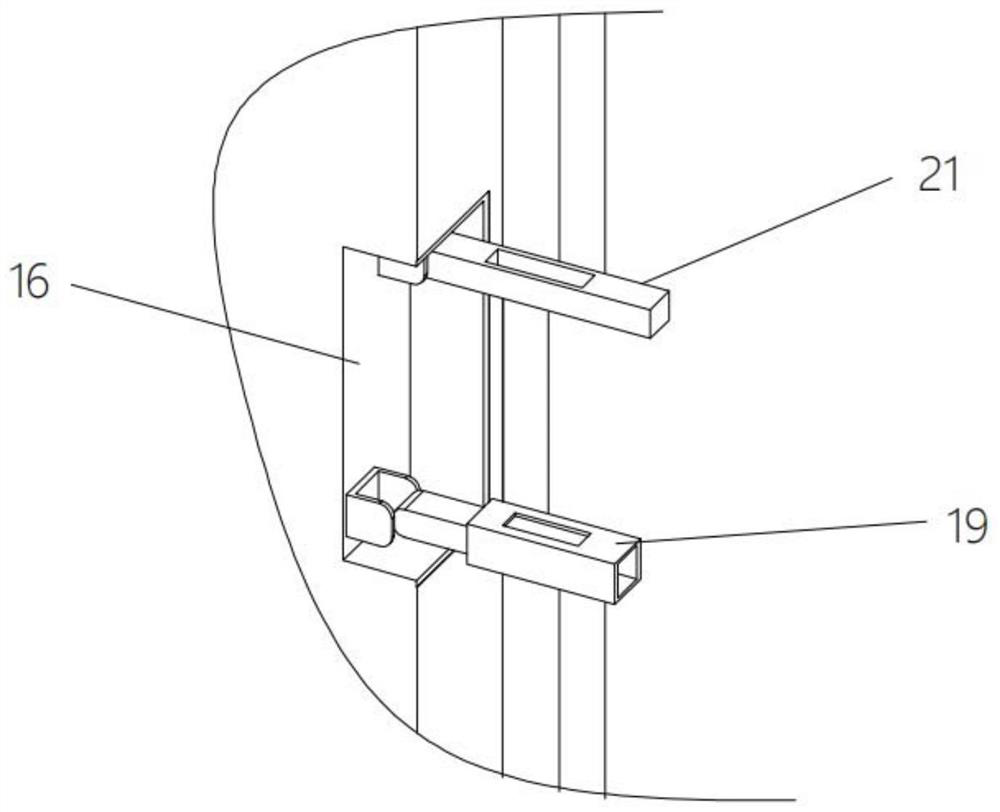

[0035] The docking piece 17 includes a sleeve rod 19 and an insertion rod 21 . The sleeve rod 19 is provided with a docking cavity for clamping the insertion rod 21 , and the docking box 16 is installed with a first hinge seat hinged with the sleeve ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com