Process for bluing surface of heating tube by adding color

A technology of adding color and heating tubes, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of short service life, easy rust of heating tubes, etc., and achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] By adding a layer of blue-colored coating to the surface of the heating pipe used in the electrical appliance, the invention makes the surface of the heating pipe not easy to rust, has better reduction degree of the heating pipe, uniform color, no color fading, and better protection of hair The heat pipe is not easy to be damaged and prolongs the service life.

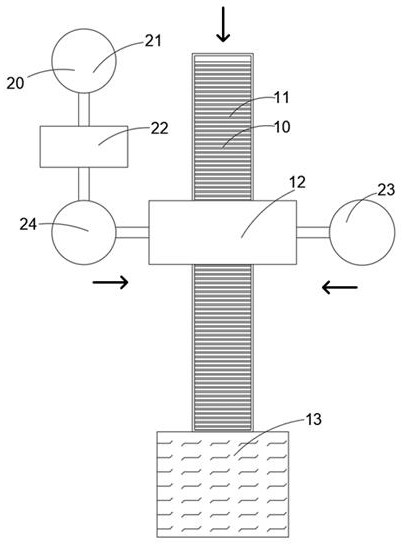

[0019] like figure 1 As shown in the figure, a process of adding color to the surface of a heating tube and turning blue includes a transmission unit 10 and an addition unit 20. The transmission unit 10 is provided with a conveyor belt 11, an oven 12 and a water tank 13, and the conveyor belt 11 is provided with all the The oven 12 is provided with a spray gun and a mixing chamber, the conveyor belt 11 passes through the lower end of the oven 12, and one end of the conveyor belt 11 is provided with the water tank 13, and the water tank 13 There is cooling water in it.

[0020] The adding unit 20 has a liquid a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com