Machine gun rack rotating device for fighter plane and machine gun rack of fighter plane

A technology for rotating devices and fighter jets, which is applied in military equipment configuration, aircraft parts, transportation and packaging, etc. It can solve problems such as increased local friction of rotating parts, difficult rotation of columns, structural deformation and damage of machine gun rack rotating devices, etc., to achieve The effect of increasing the connection strength and correct installation orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

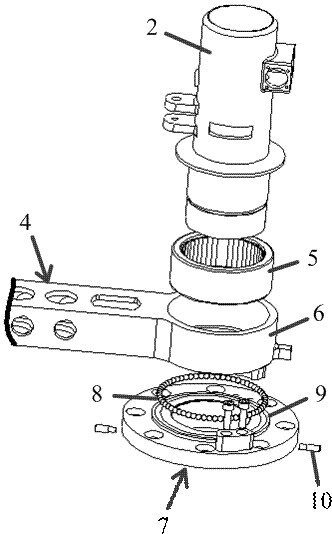

[0065] A machine gun mount turning device for fighter jets is described, such as figure 1 shown, including:

[0066] Machine gun mount base 1, connected to the floor inside the combat helicopter;

[0067] The machine gun support column 2 is arranged on the machine gun mount base 1;

[0068] The seat 3 is rotated, and the rotating seat 3 is rotatably arranged on the machine gun support column 2 through the rotating beam 4; and the rotating beam 4 is rotatably connected to the machine gun support column 2 through the needle roller bearing 5 without an inner ring . like figure 2 As shown, the end of the above-mentioned rotating beam 4 facing the machine gun support column 2 also has an annular connecting sleeve 6; , and the circular needle in the inner cavity of the needle roller bearing without inner ring 5 is connected with the outer peripheral wall of the machine gun support column 2 by rolling friction; the needle roller bearing without inner ring 5 is arranged in the an...

Embodiment 2

[0076] A fighter machine gun mount is documented, such as Figure 5 As shown, it includes: a machine gun mount turning device for a fighter; and a rotating beam 4 .

[0077] The machine gun rack rotating device includes:

[0078] Machine gun mount base 1, connected to the floor inside the combat helicopter;

[0079] The machine gun support column 2 is arranged on the machine gun mount base 1;

[0080] The seat 3 is rotated, and the rotating seat 3 is rotatably arranged on the machine gun support column 2 through the rotating beam 4; and the rotating beam 4 is rotatably connected to the machine gun support column 2 through the needle roller bearing 5 without an inner ring . like figure 2 As shown, the end of the above-mentioned rotating beam 4 facing the machine gun support column 2 also has an annular connecting sleeve 6; , and the circular needle in the inner cavity of the inner ring-free needle roller bearing 5 is connected with the outer peripheral wall of the machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com